Metal/water/air reaction feedback type engine and high-speed sea flitting aircraft with diving function

A technology of aircraft and engine, applied in the field of aircraft, can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

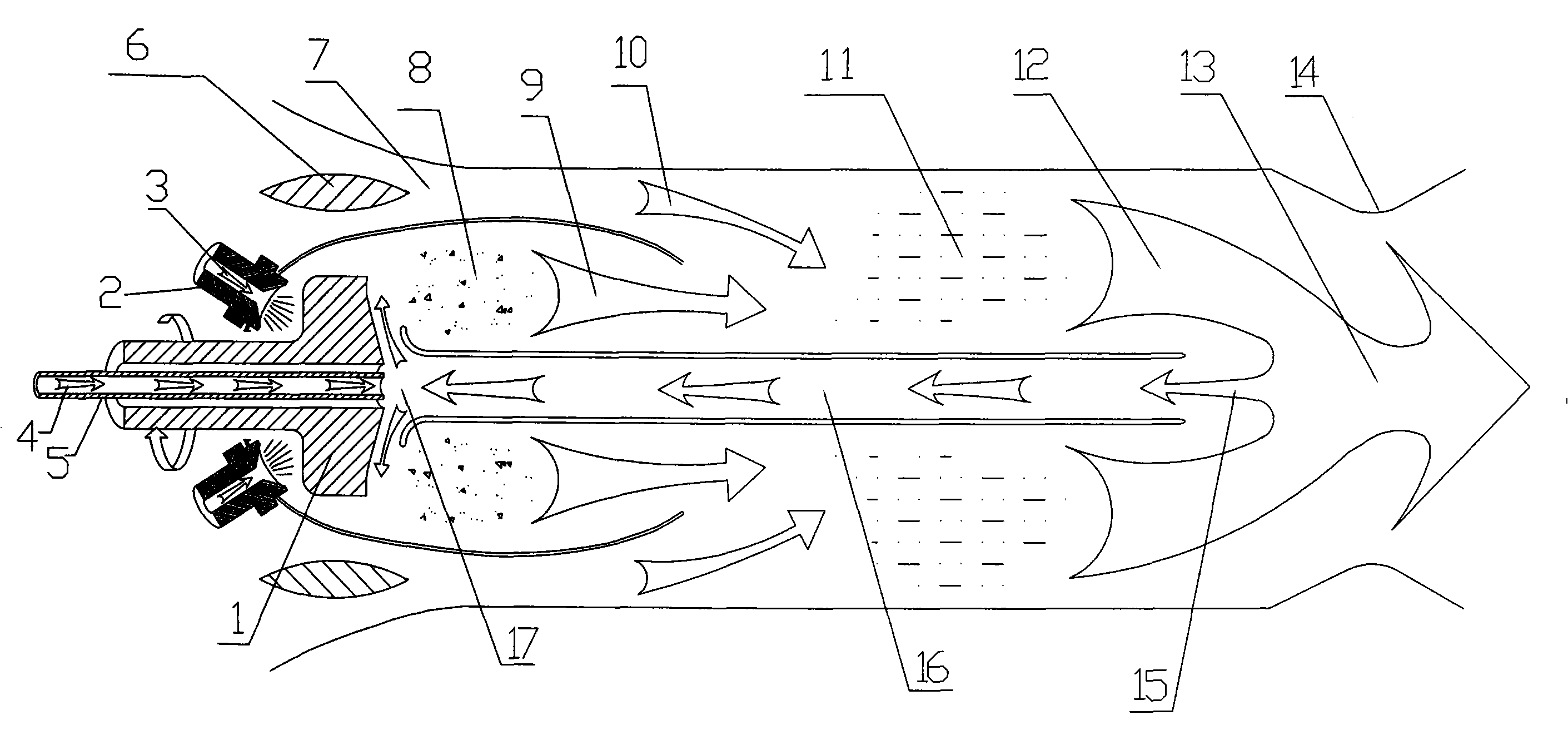

[0013] Further explanation below in conjunction with accompanying drawing

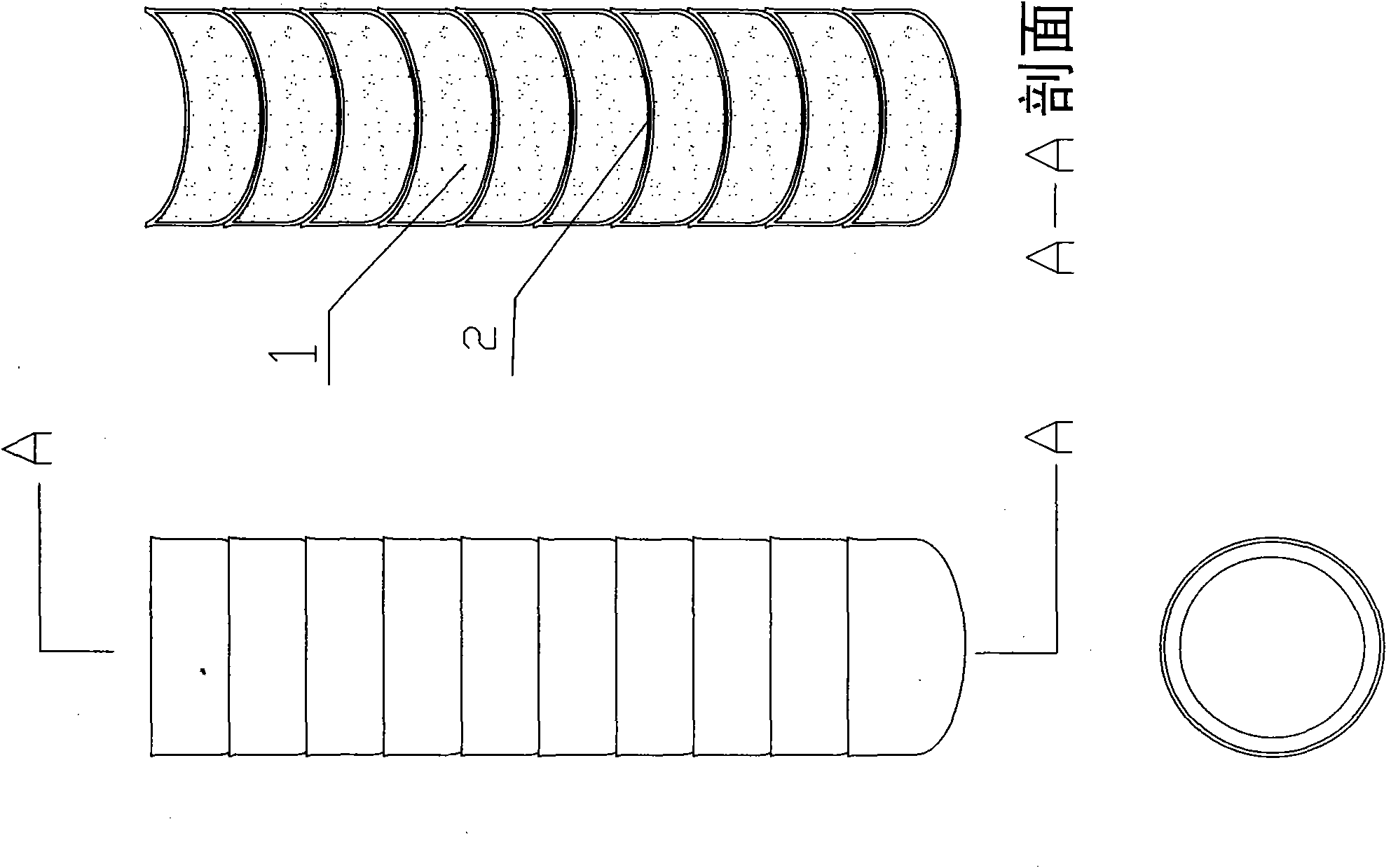

[0014] figure 1 The basic structure diagram of the metal powder unit is shown, in which: 1- is the metal powder, 2- is the aluminum film of the outer packaging of the powder, 3- the welding part of the aluminum film interface, in which the metal powder is packaged in a vacuum state, and the package is isolated after welding It prevents the contact between the external oxidant and the metal particles, and delays the oxidation process of the metal particles. The aluminum film used for packaging is broken under the action of the high-speed rotating turbine of the engine, and the broken aluminum film disintegrates into small units, which participate in combustion under high temperature conditions in the combustion chamber, laying a solid foundation for the standardized packaging of metal powder and the standardized production of cartridges. Basics; classifying encapsulated metal powders helps the aircraft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com