Automatic treatment assembly for top drive pipe

A technology of automatic processor and assembly, applied in drill pipe, casing, drilling equipment, etc., can solve the problems of high labor intensity, reduced construction efficiency, drill pipe length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

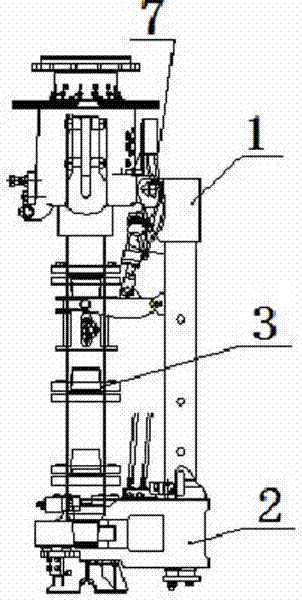

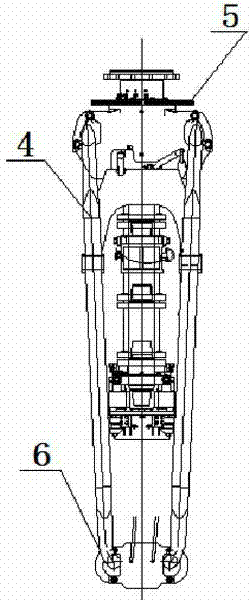

[0043] Top drive pipe automatic processor assembly, including torque arm assembly 1, back tong assembly 2, blowout preventer assembly 3, tilting mechanism 4, slewing body assembly 5, hydraulic elevator 6, hydraulic manifold 7, The upper end of the slewing body assembly 5 is connected to the gear box and moves independently of the main shaft; the torque arm assembly 1, the back clamp assembly 2, the blowout preventer assembly 3, the tilting mechanism 4, the hydraulic elevator 6, and the hydraulic manifold 7. It is hung under the rotating head and moves clockwise and counterclockwise together with the rotating head.

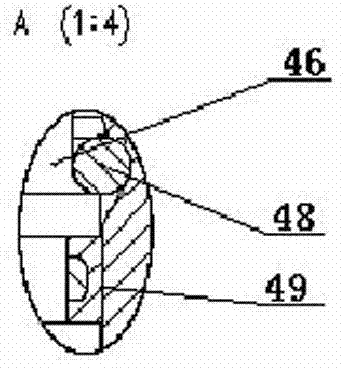

[0044] Torque arm assembly 1 includes torque beam 8, nuts 9 and 34, pin 10, pin shaft 11 and 25, bolts 12, 15 and 17, spring 13, spring post 14, washers 16 and 28, cotter pins 18 and 33, nuts 19. Bottom plate 20, spacer ring I21, spacer ring II22, spacer ring III23, back clamp suspension frame 24, copper sleeves 26, 32 and 37, rollers 27 and 29, grease nozzle 30, I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com