Automatic lifting roller blind retarder

An automatic rising and retarder technology, which is applied in the direction of door/window protection devices, windows/doors, building components, etc., can solve problems such as loud impact sound, easily damaged curtains, affecting the stability and service life of curtains, and achieves improved Effects on Stability and Lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

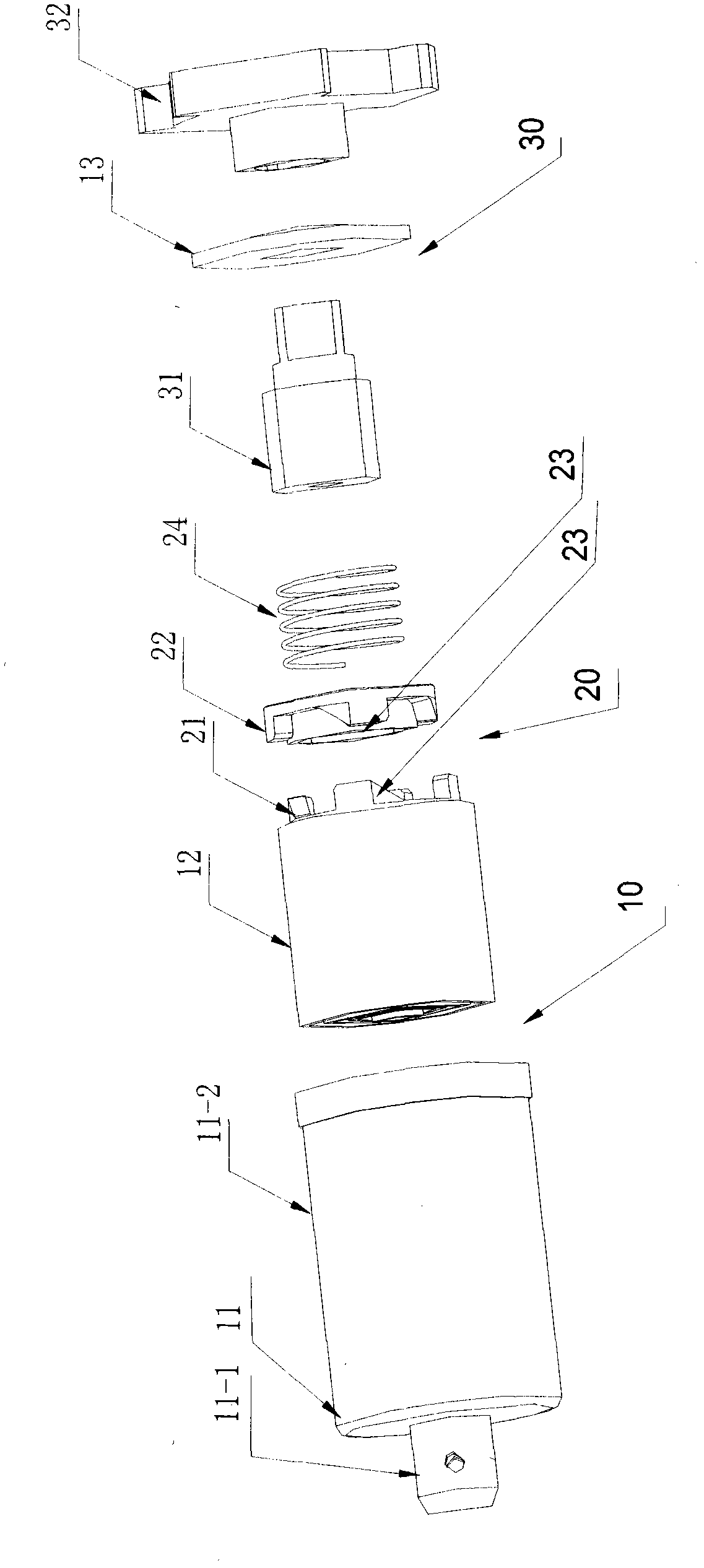

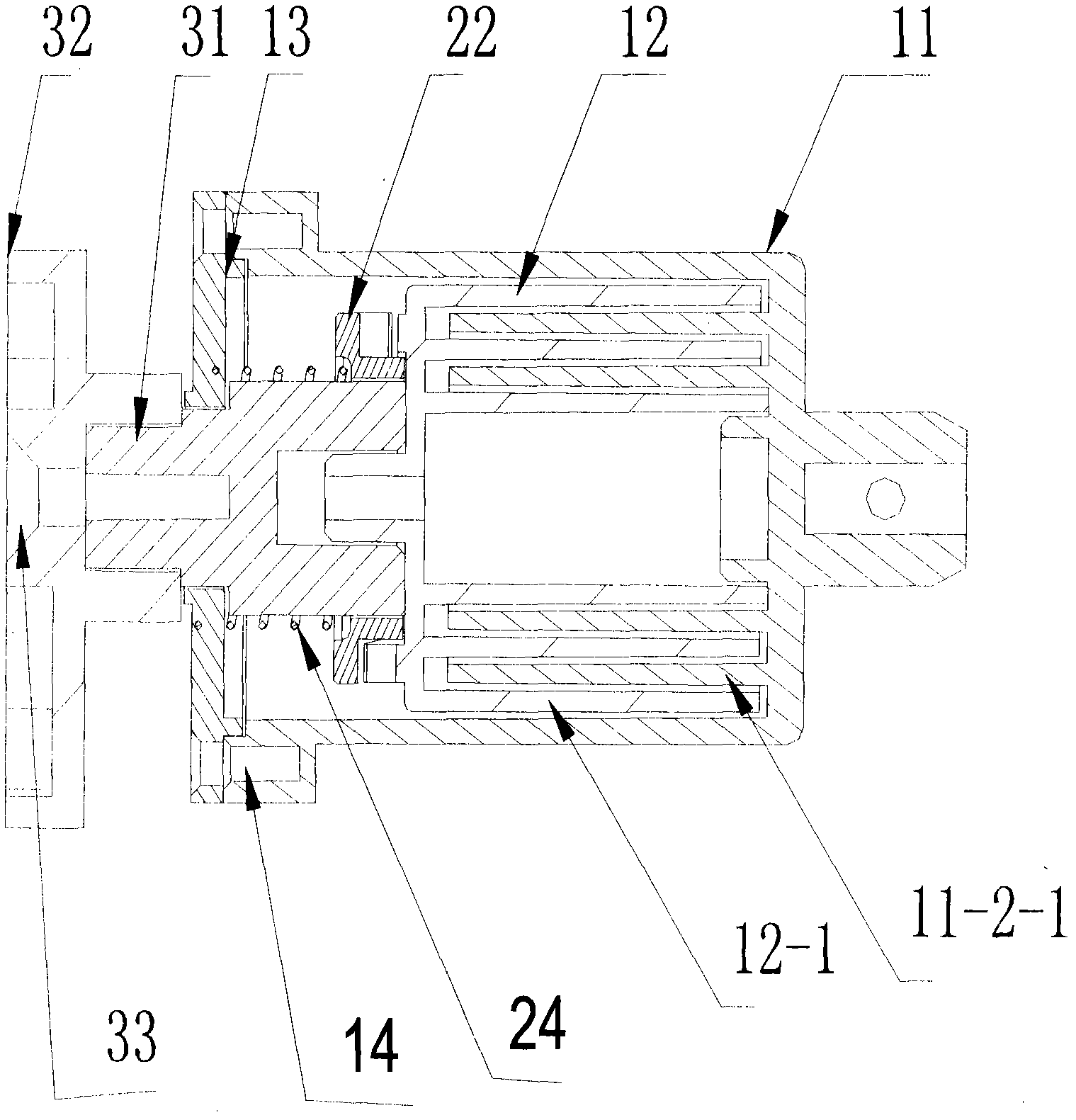

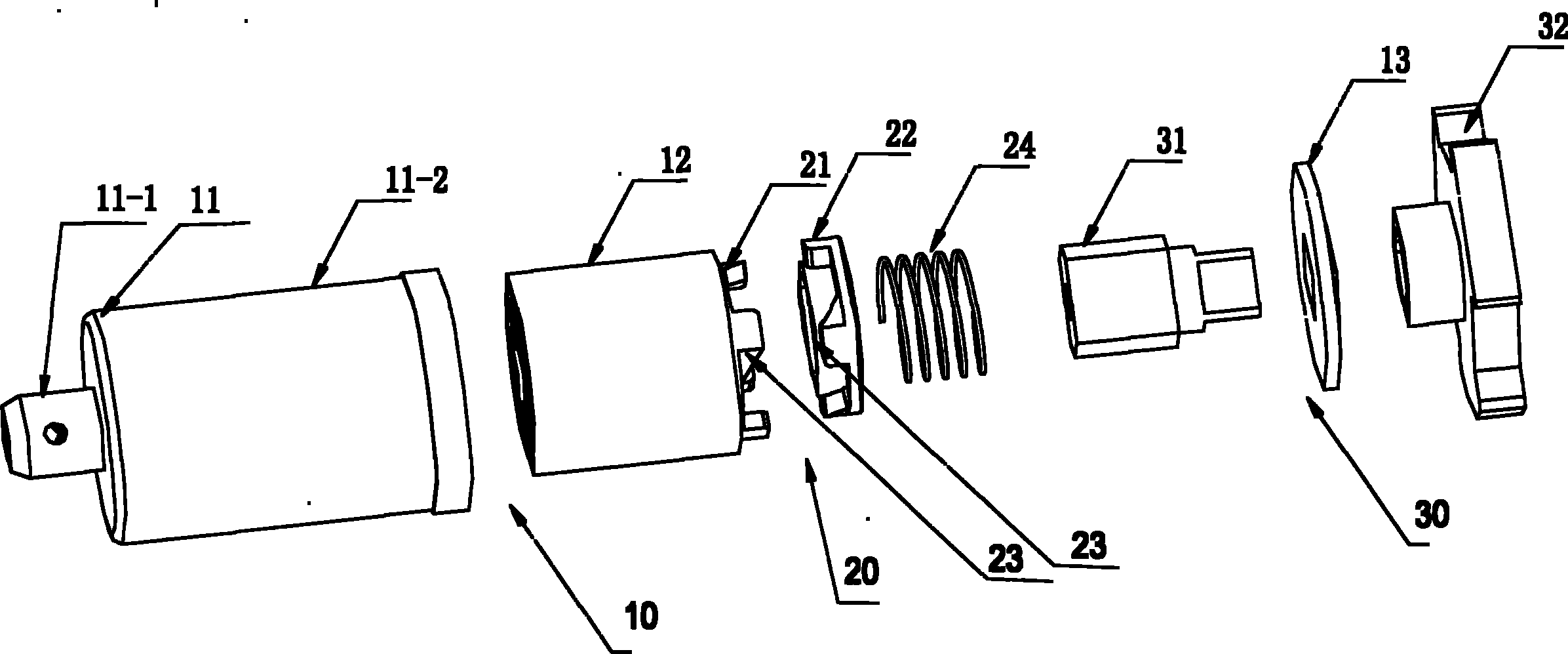

[0014] refer to figure 1 and figure 2 , the present invention provides an automatic rising roller shutter retarder, including a retarder main body 10, a clutch mechanism 20 and a transmission mechanism 30.

[0015] The retarder main body 10 includes a retarder casing 11 and a retarder core 12. One end of the retarder casing 11 has a protruding shaft 11-1, one end of the retarder casing 11 has a protruding shaft 11-1, and the other end of the retarder casing 11 has a The container 11-2 has a convex-concave ring 11-2-1 inside the container 11-2. One end of the retarder core 12 has a convex-concave ring 12-1 that fits with the convex-concave ring 11-2-1. The main body of the retarder There is also a sealing cover 13 on one side, and the sealing cover 13 is connected with the retarder housing 11 by screws 14. The sealing cover 13 makes the chamber 11-2 of the retarder housing 11 form a closed space. The chamber 11-2 of the device housing 11 is filled with damping oil.

[0016]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com