Construction method of utilizing short-frame cement stirring pipe to produce cement stirring pile

A technology of cement mixing pile and construction method, which is applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems such as inability to construct the mixing pile, high cost of rotary jetting pile, speeding up the progress of the project, etc., so as to achieve soft foundation treatment, The effect of speeding up the progress of the project and saving the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

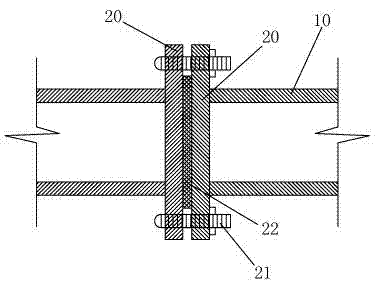

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

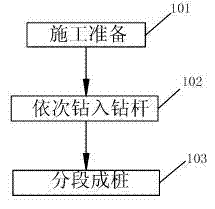

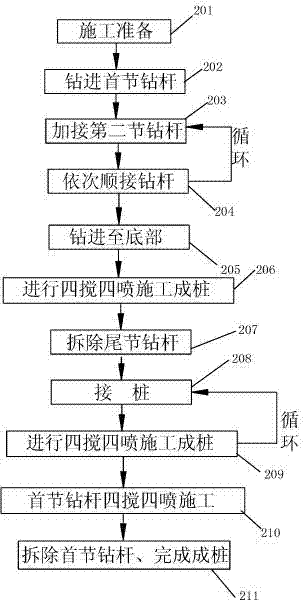

[0027] Such as figure 1 , the construction method of a kind of low-frame cement mixing pile that the embodiment 1 of the present invention provides, utilizes short-frame cement mixing pile machine to implement cement mixing pile, comprises the following steps:

[0028] Step S101, preparation before construction: according to the height requirements of the construction site, determine the height of the low-frame cement mixing pile machine, and refit the short-frame cement mixing pile machine according to this heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com