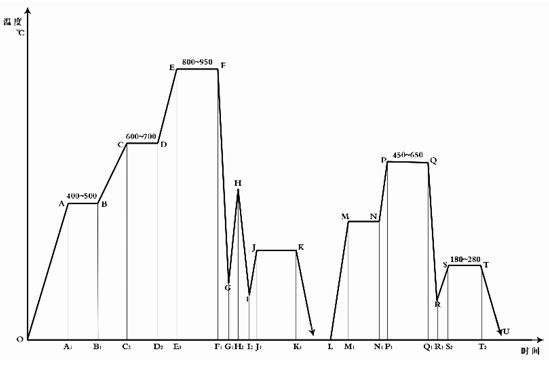

Steel isothermal quenching-tempering cooling technology

A technology of austempering and cooling technology, which is applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc. It can solve the problems that the quality and technical indicators of large workpieces are difficult to meet the standards, there is no breakthrough in the hardenability of steel, and the energy consumption of heat treatment is large. Solve hardenability problems, improve heat treatment quality, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Heat treatment difficulty factor:

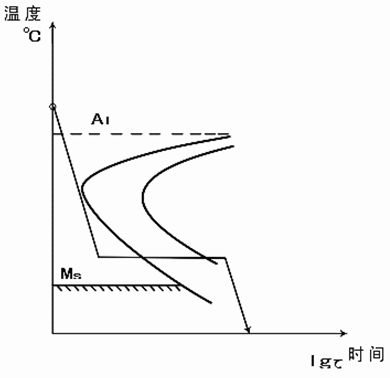

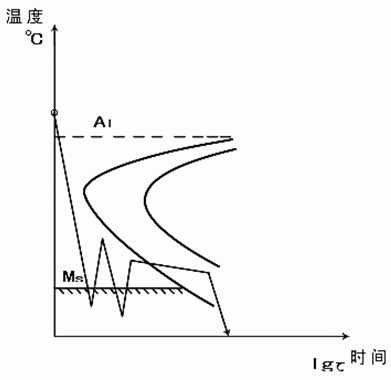

[0069] After the steel is heated and transformed into austenite, it does not transform immediately after cooling in water to the critical point A1. The austenite existing at this time is called supercooled austenite. When the supercooled austenite is cooled to a certain temperature lower than Ar1, it will decompose and transform into other organizations.

[0070] The difficulty factor of heat treatment is that after the steel is austenitized (the temperature inside and outside the workpiece is uniform, the austenite is homogenized, the phase transformation is completed, the austenite grains cannot grow, and the cost is low), the core part is cooled in water. When it reaches a certain temperature lower than Ar1, it will decompose and transform into martensite or lower bainite.

[0071] The heat treatment difficulty coefficient is calculated by the formula:

[0072] the

[0073] In the formula, N — heat treatment difficulty coeffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com