Heat insulation UV-resistant thin film

An anti-ultraviolet and film technology, applied in the direction of film/flaky adhesives, adhesives, etc., can solve the difficulty of energy-saving promotion and application of architectural glass film, the high cost of metal-coated thermal insulation film, and the restriction of the use of thermal insulation film, etc. problems, to achieve excellent thermal insulation effect, good thermal insulation and anti-ultraviolet effect, and the effect of optimizing structure and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the drawings and examples, but the embodiments of the present invention are not limited thereto.

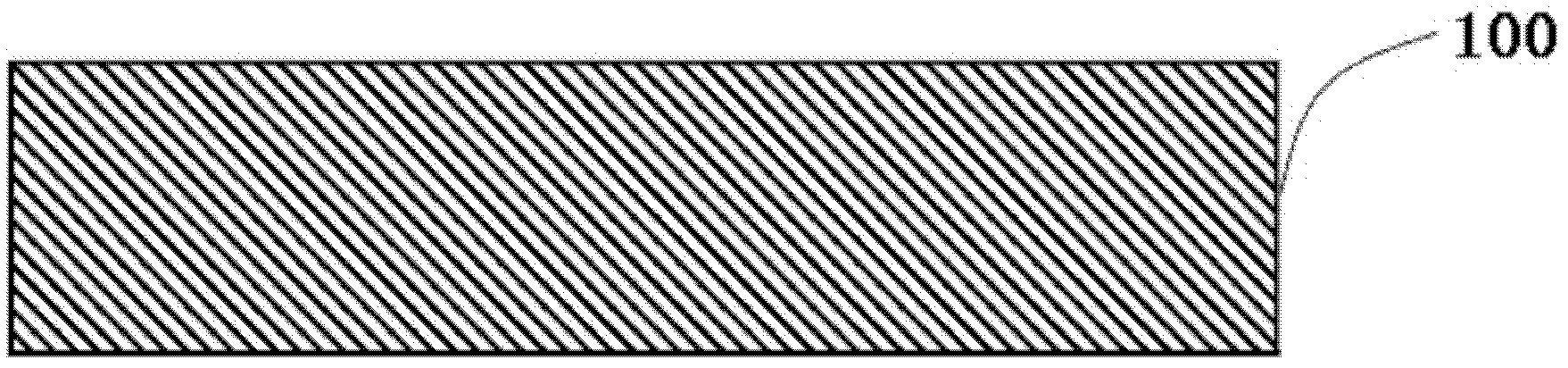

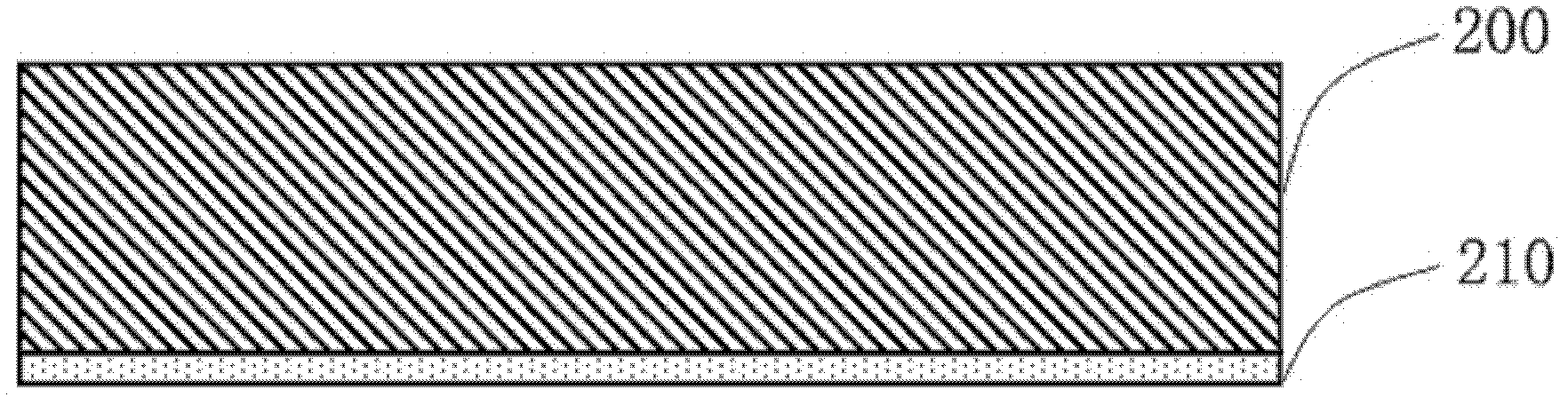

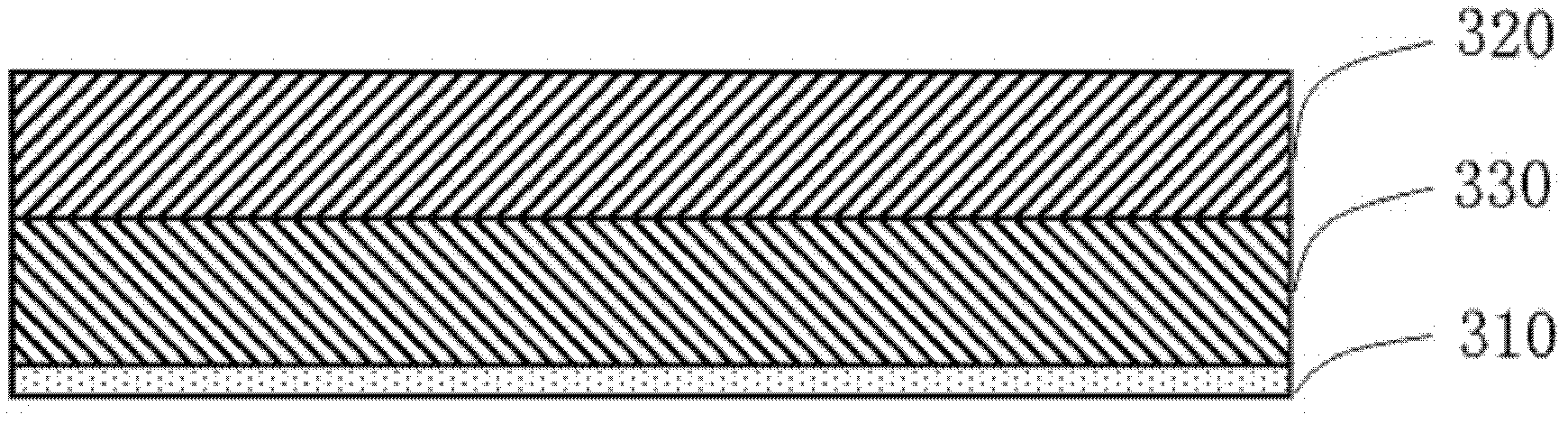

[0023] figure 1 A schematic cross-sectional structure diagram of a heat-insulating and UV-resistant film according to an embodiment of the present invention is shown. Such as figure 1 The heat-insulating and anti-ultraviolet film shown includes a structural layer 100 capable of absorbing solar heat and ultraviolet rays, and the structural layer 100 is made of a mixture of components ultraviolet absorber, solar heat absorber, antioxidant, antistatic agent, conductive agent, and colorant . The antioxidant in the heat-insulating and anti-ultraviolet film enhances the anti-oxidation ability of the material and improves the service life of the heat-insulating and anti-ultraviolet film; the antistatic agent reduces the surface resistance of the material to the order of 10^10 to 10^13 ohms; The conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com