Self-layering organic-inorganic nano composite emulsion and method for preparing same

A technology of inorganic nano-composite emulsion, applied in the direction of coating, etc., can solve the problems of paint film scratch resistance, poor flexibility and wear resistance, application fields that are difficult to meet high performance requirements, poor anti-adhesion, etc. , to achieve excellent slippery feeling, low viscosity and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

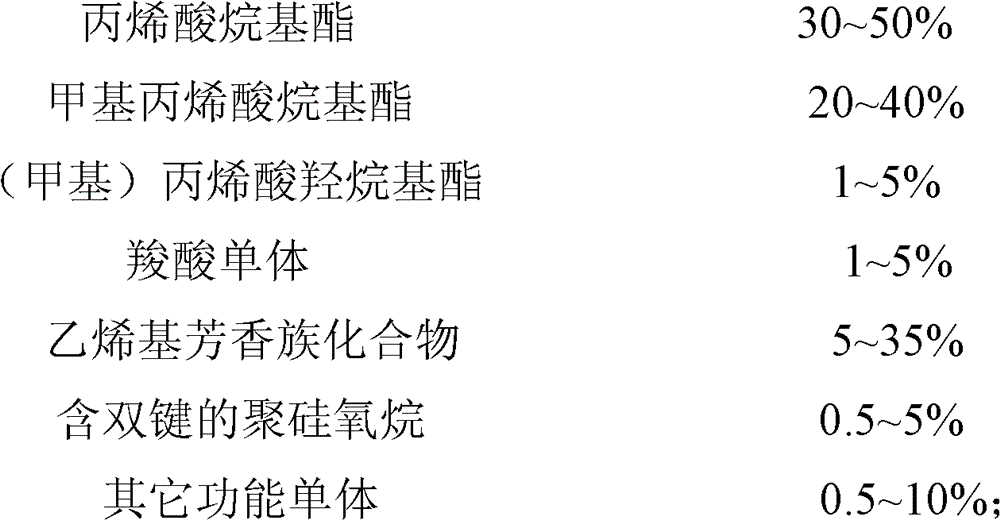

Method used

Image

Examples

Embodiment 1

[0043] Seed emulsion polymerization, inorganic components are added during seed emulsion polymerization, the specific steps are as follows:

[0044] ① Preparation of pre-emulsion: at room temperature, add 65% of the mass of emulsifier, 30% of the mass of deionized water, mixed monomers and dodecyl mercaptan into the pre-emulsification tank, and keep stirring at a stirring rate of 500rpm 15min obtains monomer pre-emulsion;

[0045] ②Preparation of seed emulsion: Add 35% of the mass of emulsifier, 50% of the mass of deionized water, ammonium bicarbonate, and inorganic components into the polymerization kettle, mix evenly at a stirring rate of 300rpm and heat up; when the temperature reaches 60°C , with a constant stirring rate of 100rpm, add 10% of the mass of the monomer pre-emulsion; add an initiator solution composed of 33% of the mass of the initiator and 5% of the mass of deionized water, continue to heat up to 82±1°C, and keep warm 15min obtains seed emulsion;

[0046] ③...

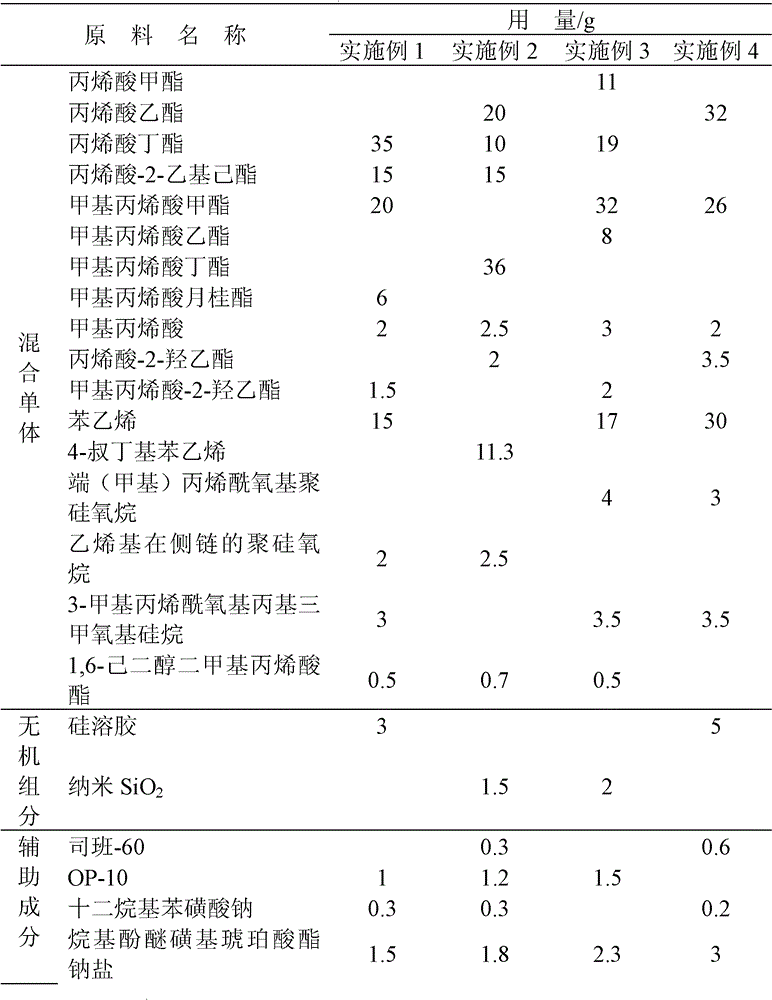

Embodiment 2~4

[0051] Repeat the method of Example 1 with the content of each component specified in Table 1 below, and the test results are shown in Table 2.

[0052] Table 1

[0053]

[0054]

[0055] Table 2

[0056]

Embodiment 5

[0058] For seed emulsion polymerization, the inorganic components are added during heat preservation. The specific steps are as follows:

[0059] ① Preparation of pre-emulsion: At room temperature, add 54% of the mass of the emulsifier, 37% of the mass of deionized water, all mixed monomers and dodecyl mercaptan into the pre-emulsification tank, and continue at a stirring rate of 500rpm Stir for 15min to obtain monomer pre-emulsion;

[0060] ②Preparation of seed emulsion: Add 46% of the mass of emulsifier, 48% of the mass of deionized water, and ammonium bicarbonate into the polymerization kettle, mix evenly at a stirring rate of 300rpm and heat up; when the temperature reaches 60°C, keep stirring at a constant rate 100rpm, add 15% of the mass of the monomer pre-emulsion; add an initiator solution composed of 40% of the mass of the initiator and 2% of the mass of deionized water, continue to heat up to 82±1°C, and keep warm for 15min to obtain a seed emulsion ;

[0061] ③Dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com