Method for improving methane yield through anaerobic fermentation of low organic matter sludge by pretreatment

A sludge anaerobic fermentation and pretreatment technology, applied in the field of solid waste recycling, can solve the problems of difficult anaerobic stable process treatment and disposal, difficulty in starting low-organic sludge, unstable gas production, etc. The effect of gas production rate, promotion of resource utilization of low organic matter sludge, and shortening of sludge residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

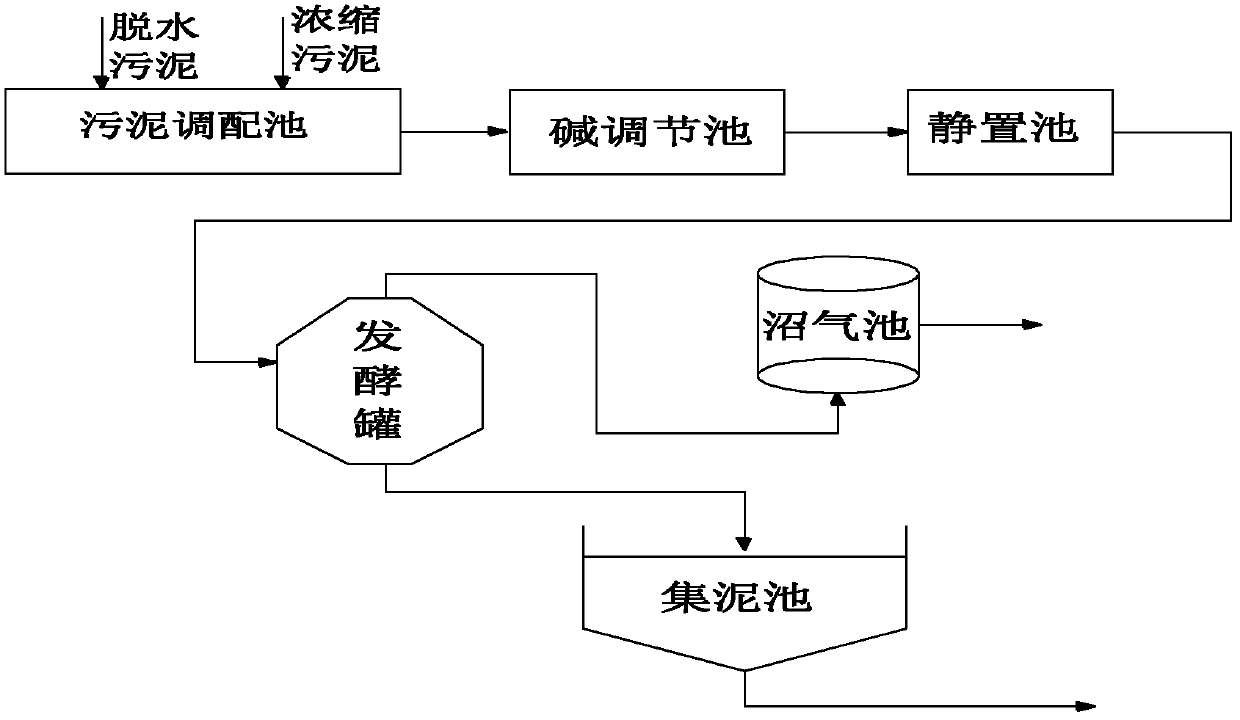

[0027] figure 1 It shows the flow chart of the method for improving biogas production by anaerobic fermentation of low-organic sludge by alkaline hydrolysis pretreatment of the present invention.

[0028] Take the dewatered sludge (water content of 78.91%) and concentrated sludge (water content of 96.17%) from a sewage treatment plant in a certain area to form a mixed sludge with a water content of 90.0% in the sludge mixing tank. The organic solids accounted for 32.5% of the total solids. Then put the above-mentioned sludge into the alkali regulating tank, add sodium hydroxide under the stirring condition of 120rpm, the dosage of sodium hydroxide is 0.05g / gVS, after stirring, let it stand in the standing tank for 24h, and then add hydrochloric acid Adjust the pH to 7.5±0.5. Take 1L of the treated sludge and put it into a 20L fermenter with an effective volume (the sludge retention time is 20d), and discharge 1L to the sludge collection tank. Collect gas through the biogas dige...

Embodiment 2

[0033] Take the dewatered sludge (water content of 79.11%) and concentrated sludge (water content of 97.62%) from a sewage treatment plant in a certain area to form a mixed sludge with a water content of 85.0% in the sludge mixing tank. The ratio of organic solids to total solids was 20.0%. Then put the above-mentioned sludge into the alkali adjustment tank, add calcium oxide under the condition of stirring at 120rpm, the dosage of calcium oxide is 0.10g / gVS, after stirring, let it stand in the standing tank for 12h, and then add hydrochloric acid to adjust the pH To 7.5±0.5. Take 1L of the above-mentioned processed sludge and put it into a 25L effective volume fermentation tank (the sludge retention time is 25d), and discharge 1L to the sludge collecting tank. Collect gas through the biogas digester every day, and control the temperature to 35±2℃, automatically adjust the pH to 7.5±0.5, and control the speed to 150rpm. After continuous operation for 2 to 3 cycles (that is, 5...

Embodiment 3

[0038] Take the dewatered sludge (water content of 78.11%) and concentrated sludge (water content of 98.35%) from a sewage treatment plant in a certain area to form a mixed sludge with a water content of 95.0% in the sludge mixing tank. The ratio of organic solids to total solids was 45.0%. Then put the above-mentioned sludge into the alkali regulating tank, add calcium hydroxide under the stirring condition of 120rpm, the dosage of calcium hydroxide is 0.15g / gVS, after stirring, let it stand in the standing tank for 18h, and then add hydrochloric acid Adjust the pH to 7.5±0.5. Take 1L of the above-mentioned processed sludge and put it into a 30L effective volume fermentation tank (the sludge retention time is 30d), and discharge 1L to the sludge collecting tank. Collect gas through the biogas digester every day, and control the temperature to 55±2℃, automatically adjust the pH to 7.5±0.5, and control the speed to 50rpm. After continuous operation for 2 to 3 cycles (that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com