Automatic balance regulating system and method of hanging scaffold for vertical shaft construction

An automatic balance and adjustment system technology, applied in the direction of clockwork mechanism, hoisting device, etc., can solve the problems of potential safety hazards, information feedback, unstable operation, etc., to improve safety and reliability, and improve leveling efficiency , to avoid the effect of operating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

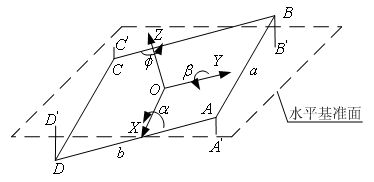

[0021] figure 1 As shown, the automatic balance adjustment system of the shaft construction hanging pan of the present invention is mainly composed of an attitude angle sensor 1, a tension sensor 2, four steel wire ropes 4 uniformly suspended hanging pan 3, and four winches 5 respectively controlling the four steel wire ropes 4 , PLC controller 6, signal acquisition card 7 constitute. Tension sensors 2 are respectively installed on the four steel wire ropes 4 evenly suspended on the suspension pan 3, and an attitude angle sensor 1 and a signal acquisition card 7 are installed on the suspension pan 3. The signal acquisition card 7 on the hanging pan 3 is connected, and the signal acquisition card 7 is connected with the PLC controller 6 arranged on the winch house through the communication cable, and the PLC controller 6 is connected with the winch 5 arranged at the wellhead through the communication cable; The X and Y inertial axes of the attitude angle sensor 1 on the dish 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com