Pay-off frame for ultrathin guide line

A pay-off frame and wire technology, applied in the field of pay-off racks, can solve problems such as wire breakage, stranded wire quality and pass rate drop, breakage, etc., to achieve stable pay-off tension, not easy to break, and smooth pay-off process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

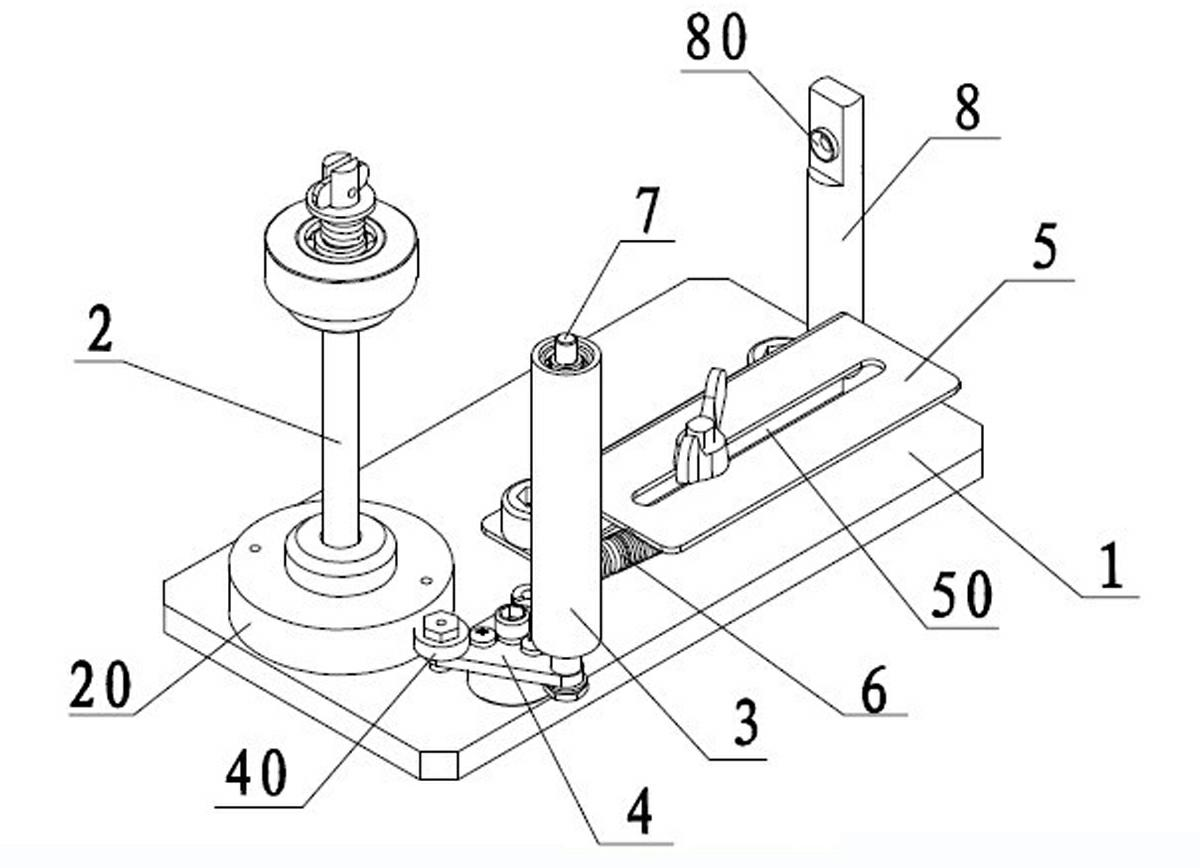

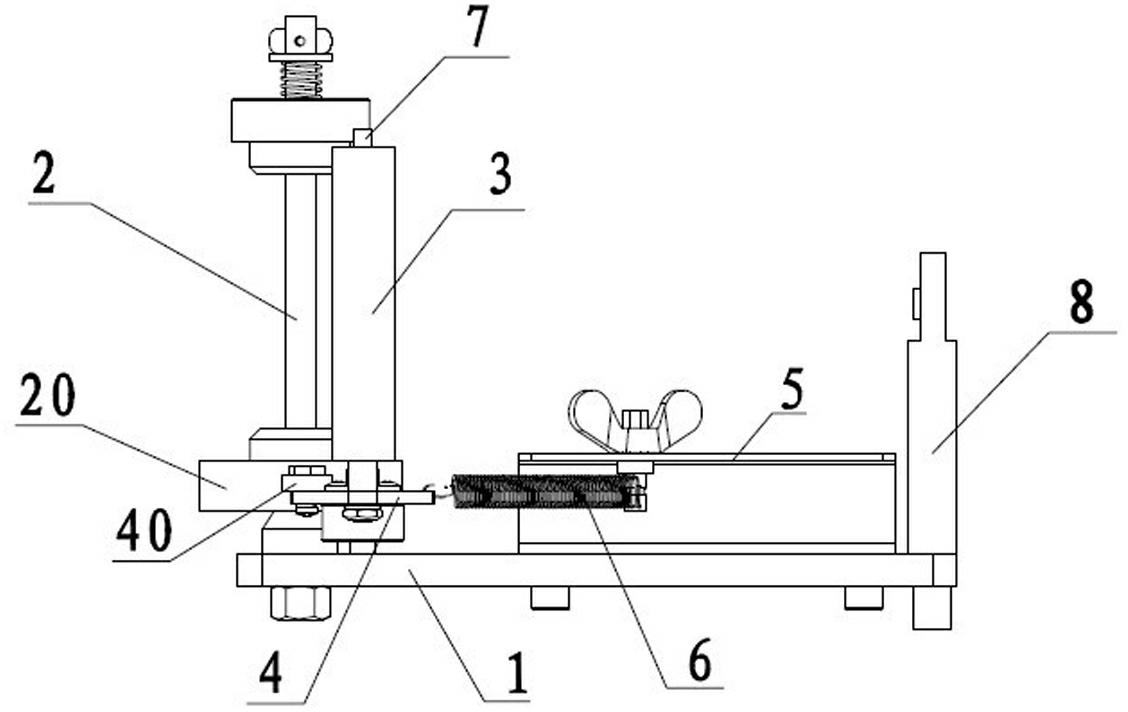

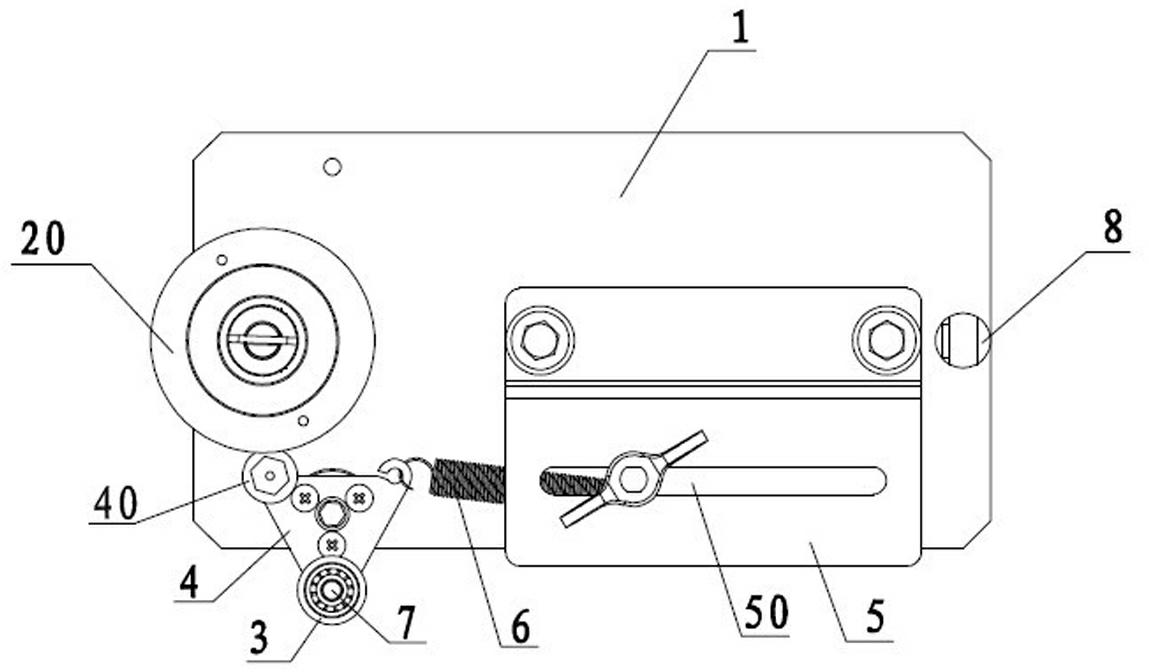

[0025] Such as Figure 1~4 As shown, a pay-off stand for ultra-fine wires includes a base 1, which is vertically arranged at one end of the base 1, and is used to cover a pay-off spindle 2 with a reel 9 wound with ultra-fine wires, a fixed shaft 7, Sleeve on the fixed shaft 7, be used for pulling the lead guide roller 3 of very fine wire when paying out, be arranged on the strut 8 on the end that is positioned at the opposite end of pay-off main shaft 2 of base 1, and be arranged on base The extension spring adjustment mechanism on the seat 1; the upper part of the pole 8 is provided with an outlet hole 80 for the ultra-fine wire to pass through.

[0026] The lower part of the pay-off main shaft 2 is provided with a rotating tray 20 that can rotate around the axial direction of the pay-off main shaft 2 and is used for supporting the pay-off reel 9 . The tension spring adjusting mechanism includes a triangular adjusting disc 4 , a fixing plate 5 arranged on one side of the...

Embodiment 2

[0030] by Figure 5 The installation of the wire reel shown and the way of paying off the wire are described as follows to the working process of the pay-off stand of embodiment 1:

[0031] Set the wire reel 9 of the ultra-fine wire on the pay-off spindle 2, and hold it by the rotating tray 20. The extension spring 6 is locked at a certain position on the guide rail 50 of the fixed plate 5 and maintains a certain tension, so that the adjustment disc 4 The friction wheel 40 is against the edge of the rotating tray 20 and gives a pressure to the rotating tray 20. Since the position of the extension spring 6 on the guide rail 50 is adjustable, the pressure of the friction wheel 40 on the rotating tray 20 is also adjustable. This pressure needs to be adjusted in advance. After testing or calculation, it is obtained to keep the tension of the ultra-fine wire at the best value when paying off, so as to balance the paying off.

[0032] When unwinding, the ultra-fine wire is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com