Pay-off device for many groups of cable reels

A pay-off device and cable reel technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as difficult tension, long time consumption, and large work space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

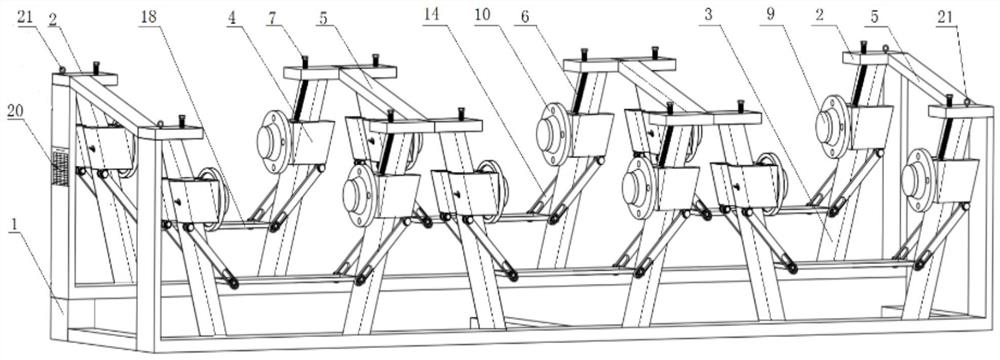

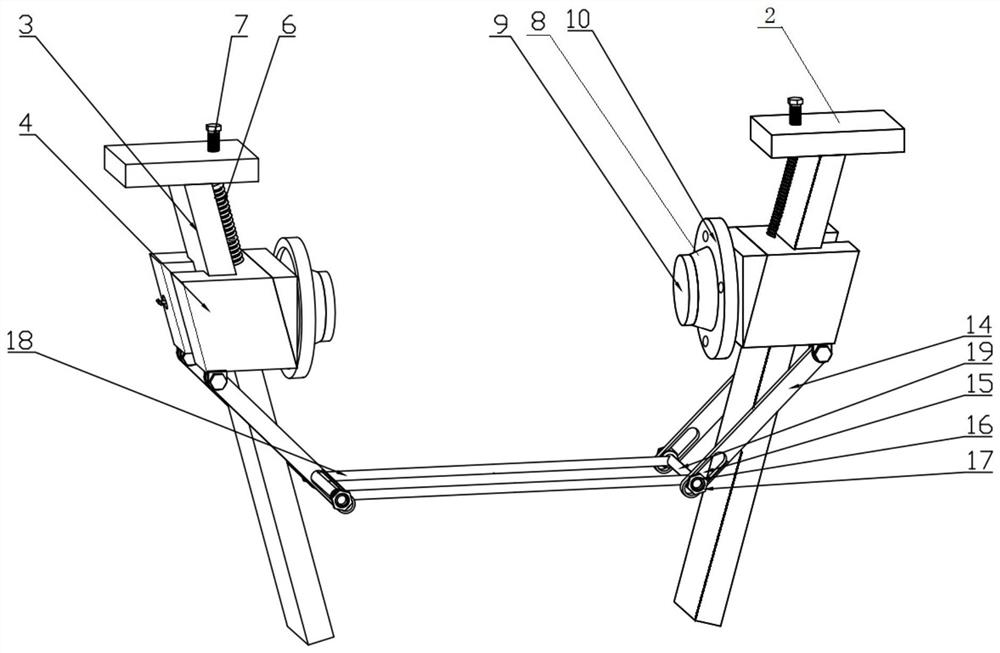

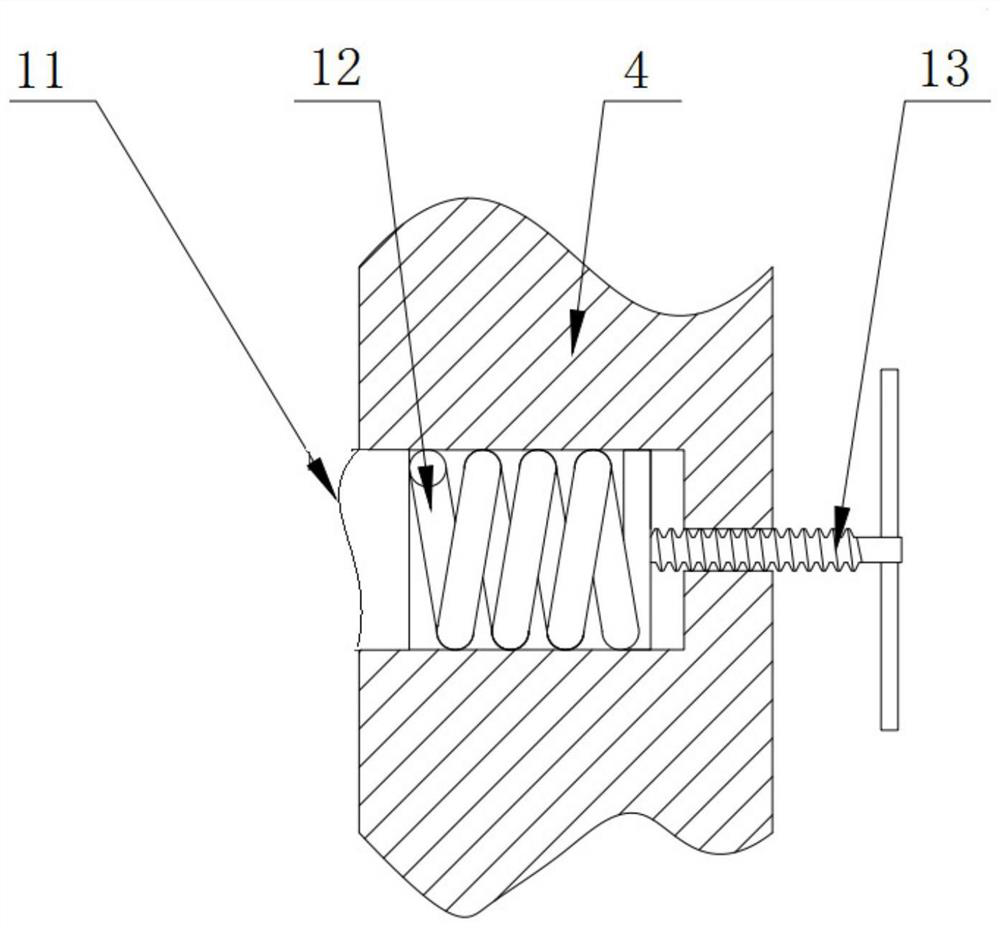

[0021] A multi-group cable reel pay-off device, such as Figures 1 to 3 , including a frame 1, the frame 1 is provided with two front and rear discharge wire frame groups along the length direction, each discharge wire frame group is composed of a number of wire release frame bodies connected in series, and the wire discharge frame body includes two inverted Trapezoidally arranged on the guide rail 3 on the frame 1, the top of the guide rail 3 is provided with a fixed plate 2, a slider 4 is slidably arranged on the guide rail 3, and a thimble shaft 8 and a thimble head are coaxially arranged on the inner side of the slider 4 9. The tension disc 10, the upper end of the slider 4 is connected to the fixed plate 2 through the tension spring 6, two pull rods 14 are hinged on both sides of the upper guide rail 3 on the lower side of the slider 4, and the two guide rails 3 of a pay-off frame body A bracket 18 is hinged between the upper pull rods 14, and the bracket 18 and the pull ...

Embodiment 2

[0033] On the basis of Embodiment 1, the rear discharge wire frame group set on the frame 1 is overall higher than the front discharge wire frame group. While facilitating the lead-out of the rear row of wires, it avoids winding of the lead-out wires from the front and rear disks.

Embodiment 3

[0035]On the basis of Embodiment 1, a connecting plate 5 is connected between the rear discharge wire frame body and the fixed plate 2 of the front discharge wire frame body arranged on the frame 1 along the front and rear direction. The connecting plate 5 connects the front and rear two discharge wire frame bodies together, making it stable in structure and safe and reliable in use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com