Turbine engine driven fracturing pump truck

A technology of turbine engine and fracturing pump truck, which is applied to motor vehicles, auxiliary drive devices, and vehicles used for freight transportation, etc., can solve the problems of increasing the total mass of vehicles, long research and development cycle, and reducing mileage, so as to reduce land acquisition and transportation costs. The effect of working area, saving manpower and material resources, and improving output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

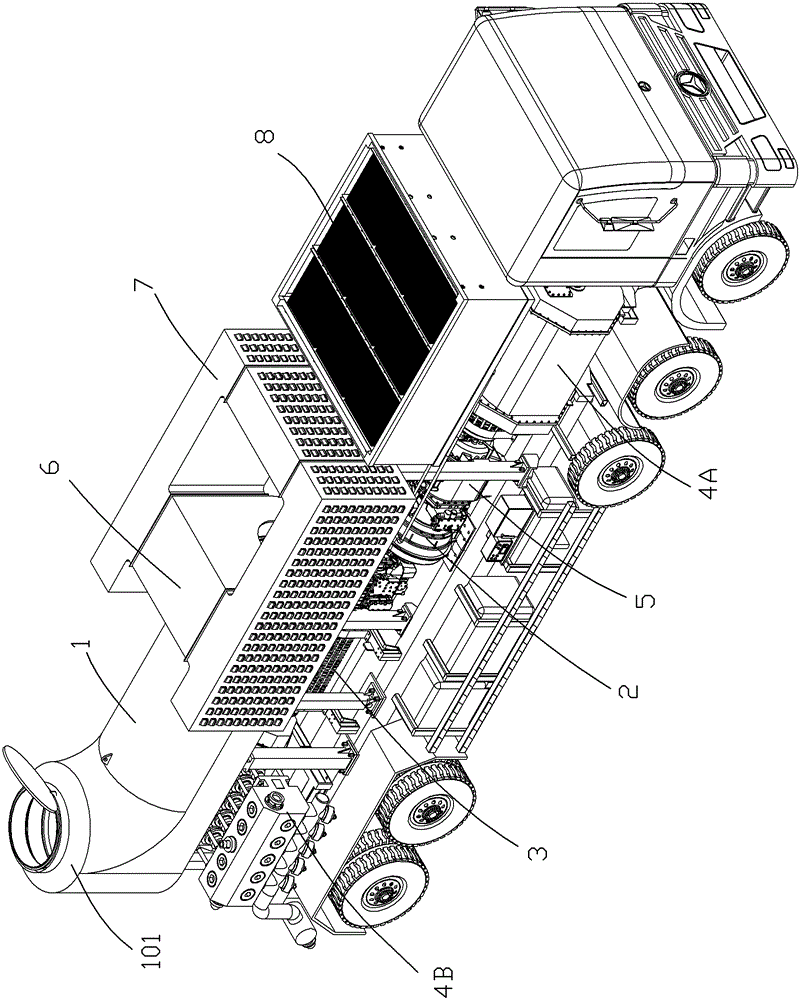

[0034] Embodiment 1 has two fracturing pumps installed horizontally opposite each other, such as figure 2 Shown:

[0035] For the convenience of expression, the direction of the chassis towards the front of the vehicle is called the front, and the direction of the chassis towards the rear of the vehicle is called the rear.

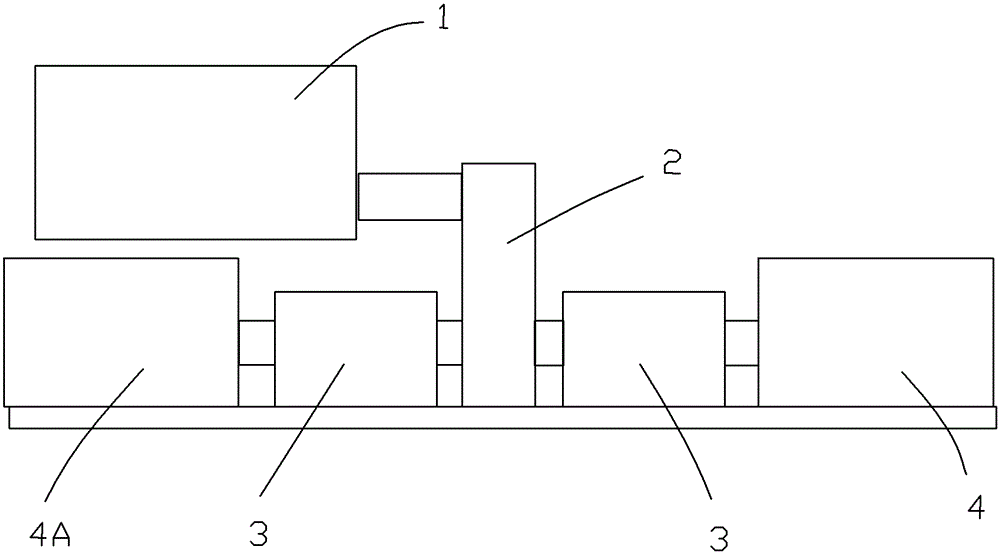

[0036] In order to effectively utilize the space of the automobile chassis, preferably, a fracturing pump is respectively installed at the front of the automobile chassis, and a reduction box 2 is installed at the middle of the automobile chassis. The reduction box 2 has two output shafts located on both sides of the reduction box, that is, the extension directions of the two output shafts are opposite. The other output shaft faces the front of the car and is connected with another fracturing pump I4A fixed on the front of the car chassis.

[0037] Furthermore, since the turbine engine has the advantages of small size and light weight, in this embodimen...

Embodiment 2

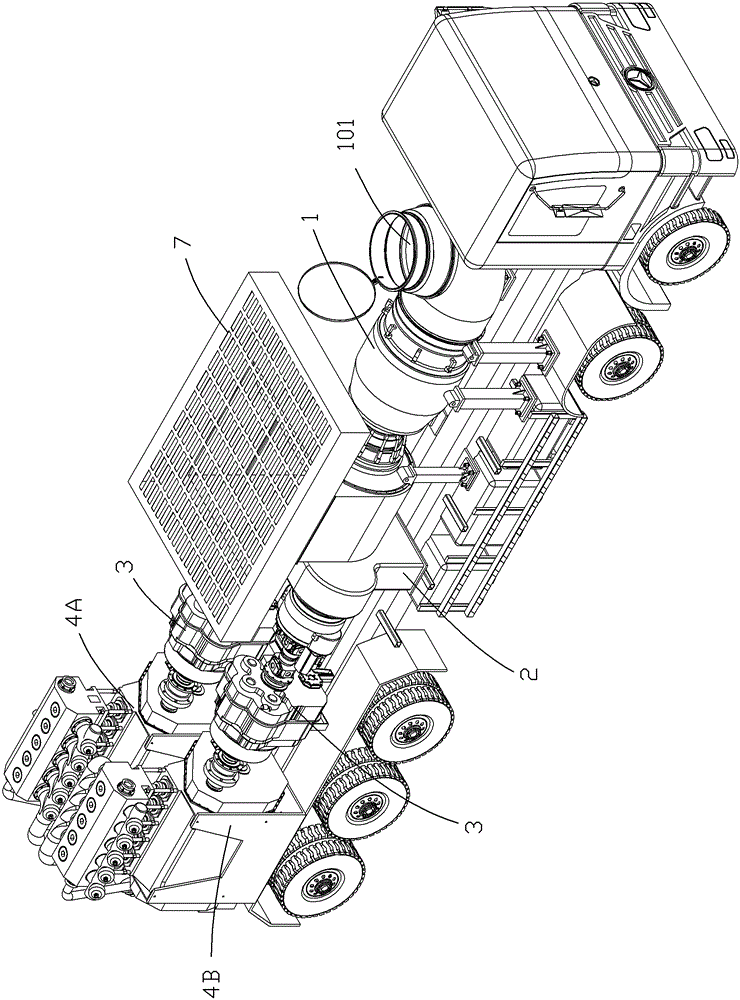

[0039] Embodiment 2 has two fracturing pumps centrally installed at the rear of the automobile chassis, such as figure 2 and Figure 4 Shown:

[0040] The turbine engine 1 is fixedly mounted on the front part of the chassis of the car, which is different from the elevated turbine engine 1 in Embodiment 1, and the turbine engine 1 in this embodiment is directly fixed on the chassis of the car. The speed reducer 2 is arranged in the middle part of the chassis of the car, and the two fracturing pumps 4 are installed side by side at the rear of the chassis of the car, so that the center of the car body is moved back, the weight of the front axle of the car body is reduced, and the stability of the chassis of the car is improved. bridge passability.

[0041] The transmission shaft of the turbine engine 1 is connected to the input shaft of the reduction box 2 . The reduction box 2 has two output shafts, and the two output shafts are located on the same side of the reduction box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com