Method for manufacturing handle base of car door

A manufacturing method and door technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of high cost and heavy weight, and achieve the effect of saving energy consumption and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

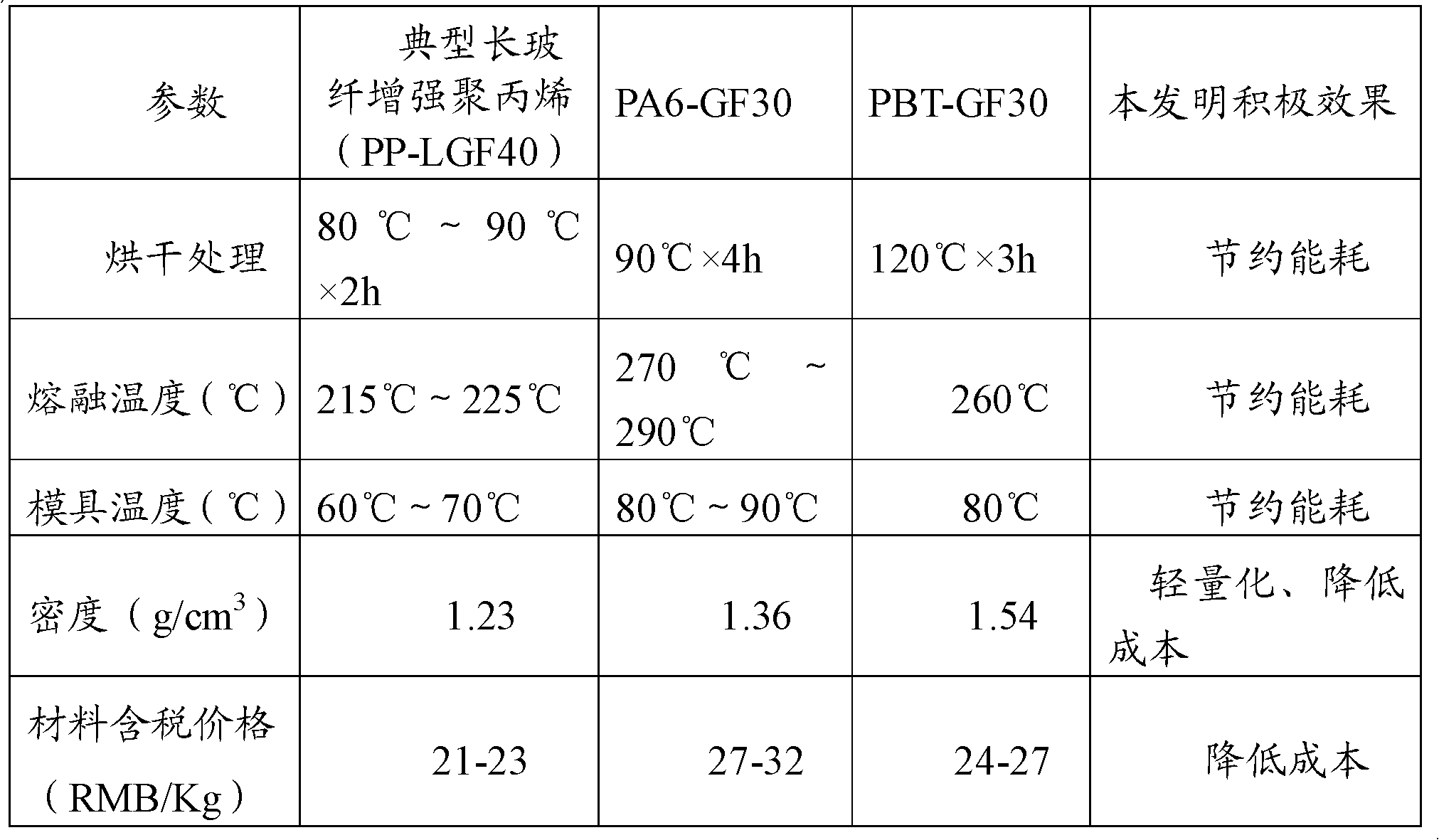

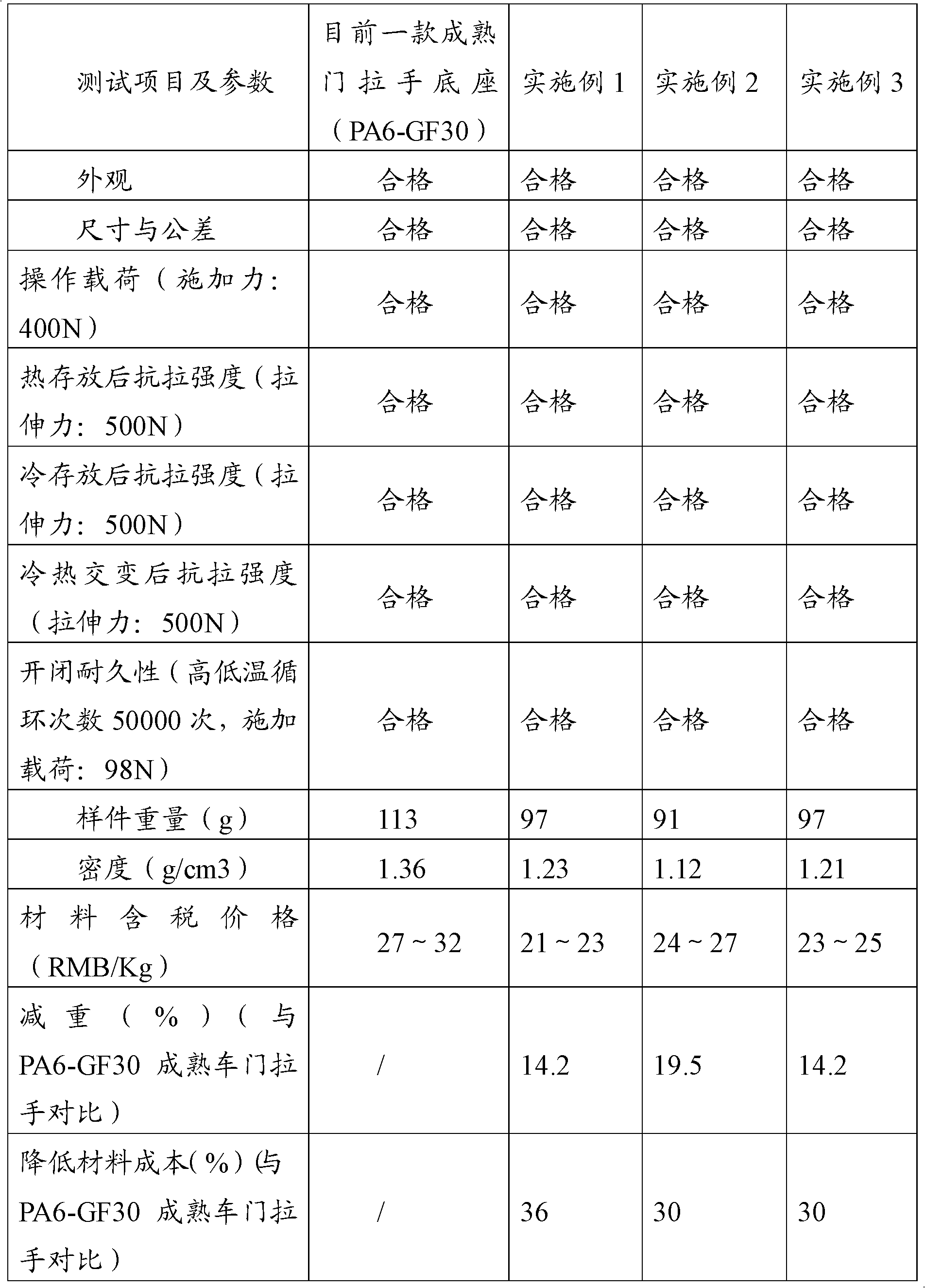

[0036] Embodiment 1: A method for making a car door handle base, using PRET A422-LG40 long glass fiber reinforced polypropylene material to make the car door handle base, specifically comprising the following steps:

[0037] Step 1: Use PRET A422-LG40 long glass fiber reinforced polypropylene material to make the required pellets, and the length of the pellets is 12mm;

[0038] Step 2: drying the pellets, the drying temperature is 90°C, and the drying time is 2 hours;

[0039] Step 3: Put the pellets into the barrel of the injection molding machine to melt, and the heating temperature of the barrel of the injection molding machine is divided into 4 sections, namely: rear section 215°C, middle section 225°C, front section 235°C, nozzle 245°C;

[0040] Step 4: Inject the molten pellets into the mold in two stages for injection molding. In order to ensure the smooth flow of the melt in the mold and avoid the incomplete filling caused by rapid cooling or the excessive temperature ...

Embodiment 2

[0042] Embodiment 2: A method for making a car door handle base, using Ticona Celstran PP-GF30-04 long glass fiber reinforced polypropylene material to make the car door handle base, comprising the following steps:

[0043] Step 1: Use Ticona Celstran PP-GF30-04 long glass fiber reinforced polypropylene material to make the required pellets, with a diameter of 3mm and a length of 12mm;

[0044] Step 2: drying the pellets, the drying temperature is 80°C, and the drying time is 2 hours;

[0045] Step 3: Put the pellets into the barrel of the injection molding machine to melt, and the heating temperature of the barrel of the injection molding machine is divided into 4 sections, namely: rear section 210°C, middle section 220°C, front section 230°C, nozzle 240°C;

[0046] Step 4: Inject the molten pellets into the mold in two stages for injection molding. In order to ensure the smooth flow of the melt in the mold and avoid the incomplete filling caused by rapid cooling or the exces...

Embodiment 3

[0048] Embodiment 3: A method for making a car door handle base, using Sabic StaMaxTM P40YM240 / 10305 long glass fiber reinforced polypropylene material to make the car door handle base, including the following steps:

[0049] Step 1: Use Sabic StaMaxTM P 40YM240 / 10305 long glass fiber reinforced polypropylene material to make the required pellets, with a diameter of 3mm and a length of 12mm;

[0050] Step 2: drying the pellets, the drying temperature is 85°C, and the drying time is 2h;

[0051] Step 3: Put the pellets into the barrel of the injection molding machine to melt, and the heating temperature of the barrel of the injection molding machine is divided into 4 sections, namely: rear section 220°C, middle section 230°C, front section 240°C, nozzle 250°C;

[0052]Step 4: Inject the molten pellets into the mold in two stages for injection molding. In order to ensure the smooth flow of the melt in the mold and avoid the incomplete filling caused by rapid cooling or the exces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com