Full-automatic chamfering machine

A chamfering machine, fully automatic technology, applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of low production efficiency, difficult to control production cost, low processing accuracy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

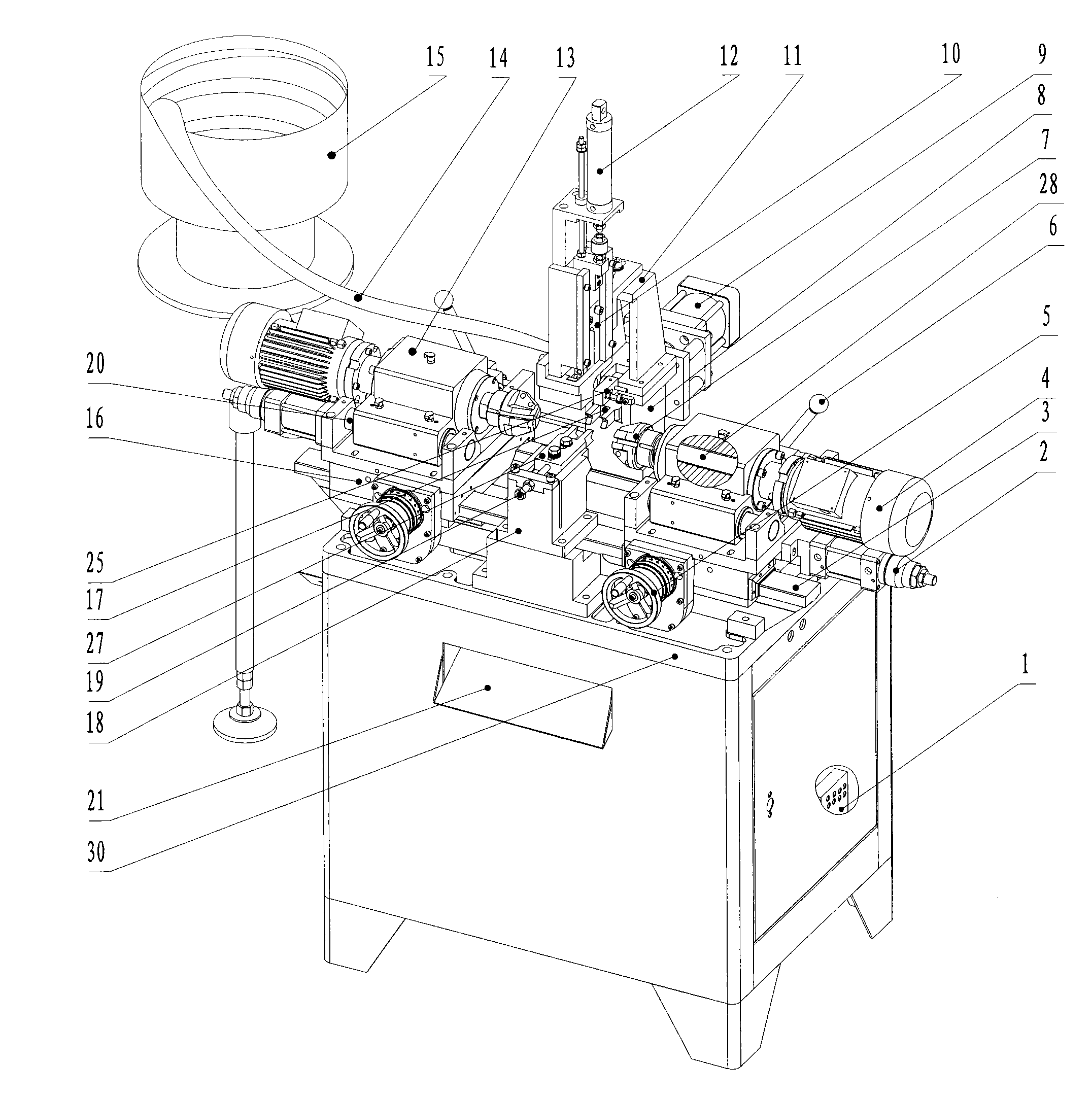

[0038] like figure 1 As shown, the fully automatic chamfering machine of the present invention includes:

[0039] A rack with a programmable logic controller (PLC) 1 inside,

[0040] The top surface of the frame is provided with a large frame base plate 30, and a feed opening is centered on the frame large base plate 30,

[0041] The rear side of the upper middle part of the large base plate 30 of the frame is provided with a feed clamp 10, the feed clamp 10 is located at the discharge end of the feed pipe 14, and the cylindrical workpiece 22 is sent to the feed clamp 10 through the feed pipe 14,

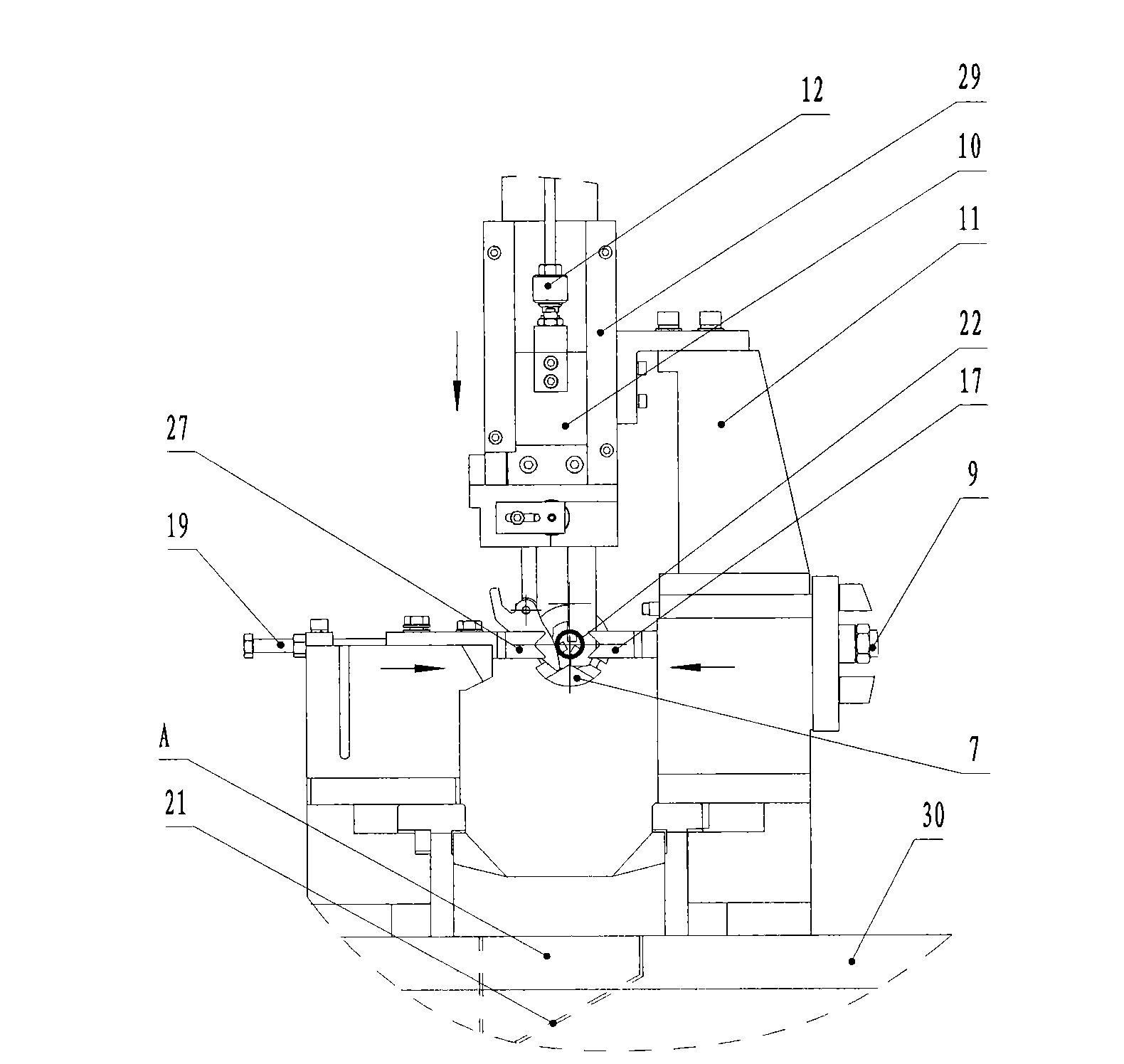

[0042] like image 3 As shown, both sides of the feed clamp 10 are provided with feed guide blocks 29 that limit its movement track, and the feed guide blocks 29 are located directly above the discharge port on the large bottom plate 30 of the frame, and are lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com