Full-automatic silver powder centrifugal filtering and washing device and silver powder washing method

A technology of centrifugal filtration and washing device, which is applied in the direction of separation method, mobile filter element filter, filtration separation, etc., which can solve the problems of increasing sodium chloride immersion silver work, not adapting to modern production, increasing wastewater treatment costs, etc., and achieves saving Drying time, improvement of filtration and separation effect, and effect of saving treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

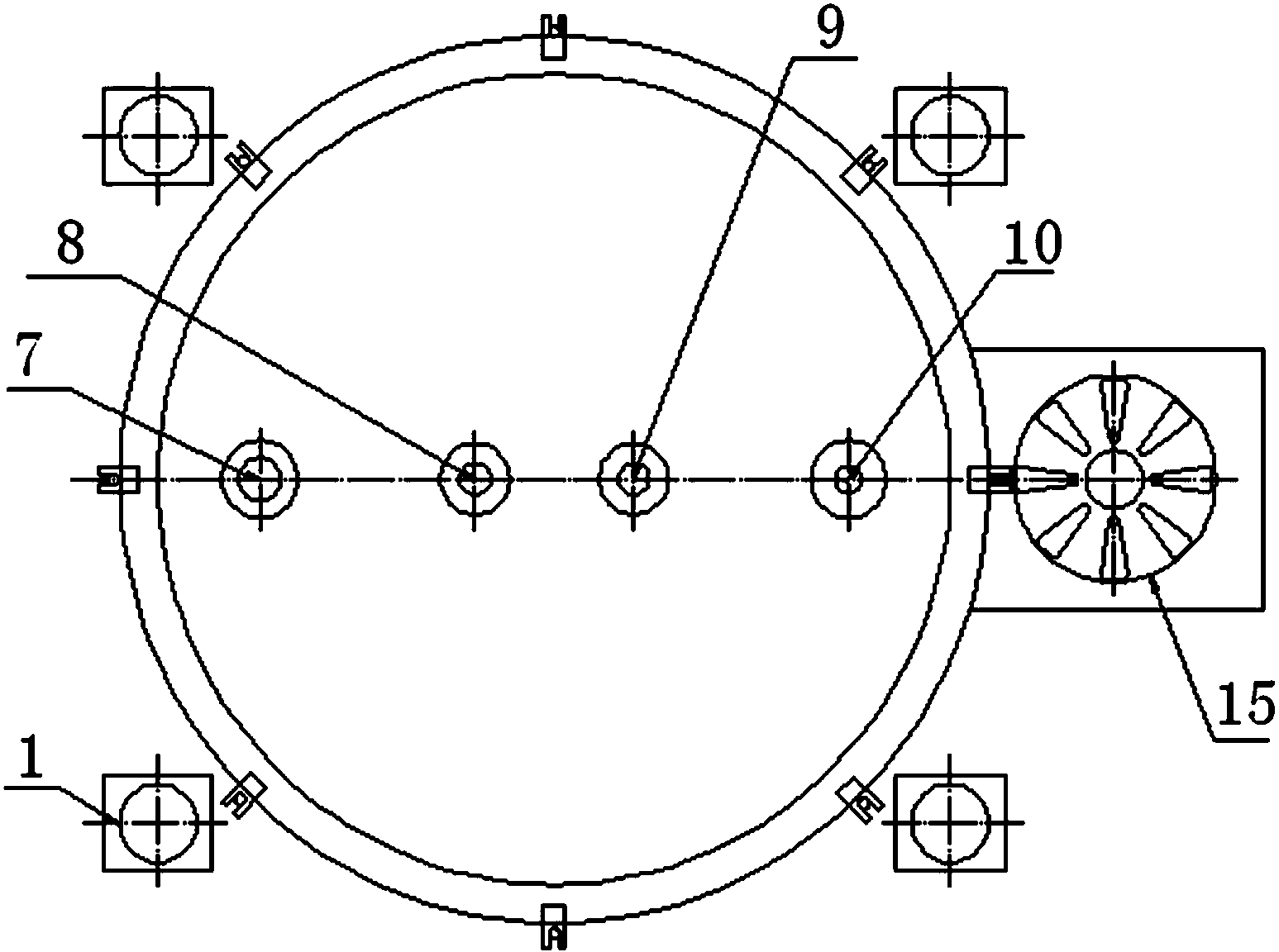

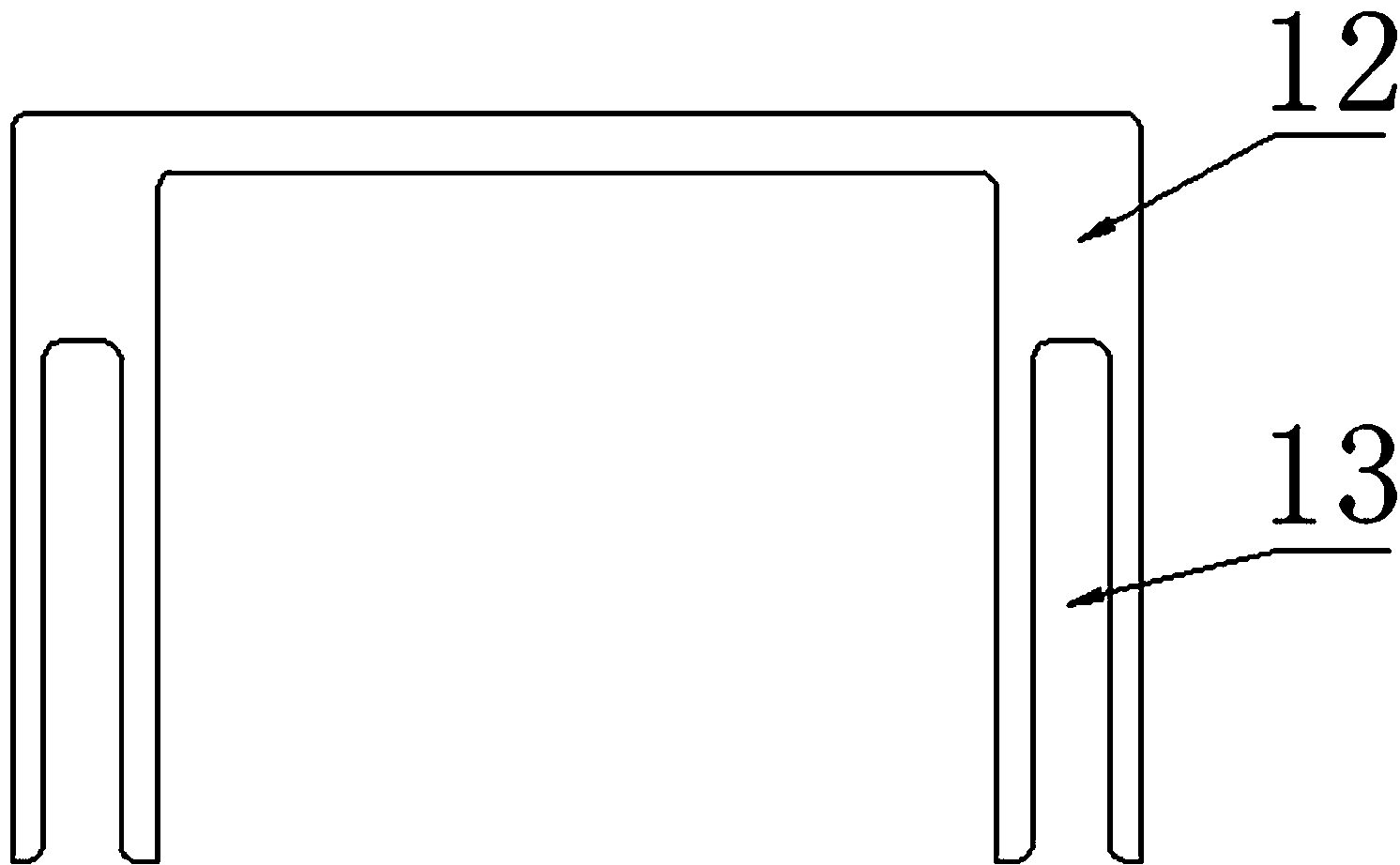

[0019] As shown in the figure, the device of the present invention includes a base 1 , a casing 5 installed on the base, and a cover 6 mounted on the top of the casing. A vertical center shaft assembly 2 is arranged inside the casing 5 , an outer drum 11 fitted on the center shaft assembly 2 and fixedly coupled with the center shaft assembly 2 , and an inner drum 12 arranged inside the outer drum. At least two vertical fixing pins 14 are evenly distributed on the inner bottom plane of the outer drum 11, and at least two vertical pins recessed into the side wall of the inner drum are evenly arranged corresponding to the bottom end of the inner drum 12. The hole 13 is used to fit the inner drum 12 to the outer drum 11 by inserting the pin hole 13 into the fixing pin 14 to form a centrifugal device with a double drum structure. In this example, four fixing pins 14 are symmetrically arranged on the inner bottom plane of the outer drum 11 , and four pin holes 13 are symmetrically a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com