Helium-recovery plant

A technology for recycling equipment and equipment, applied in lighting and heating equipment, purification/separation of inert gas, liquefaction, etc., can solve problems such as underutilized capacity and infeasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

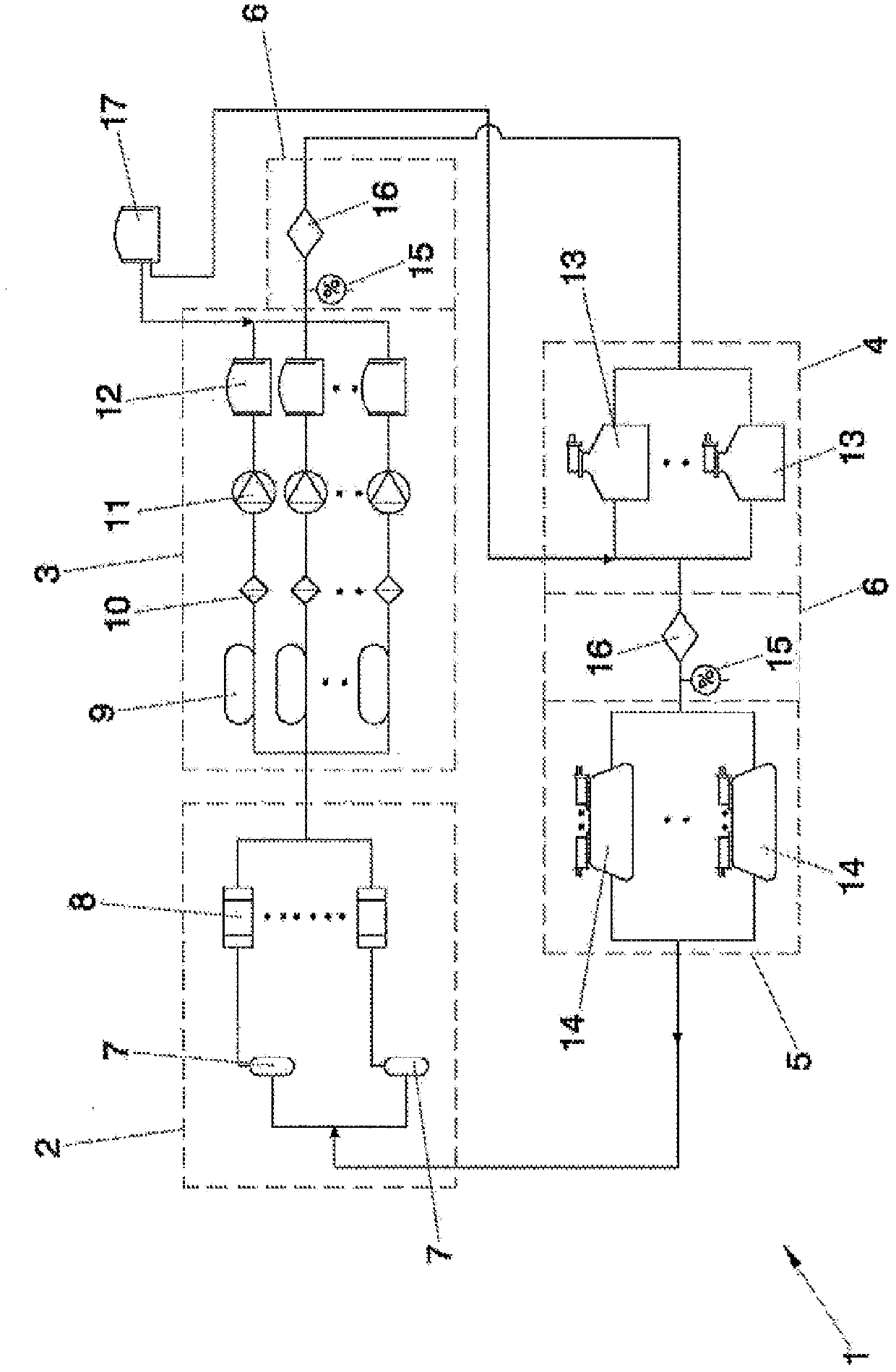

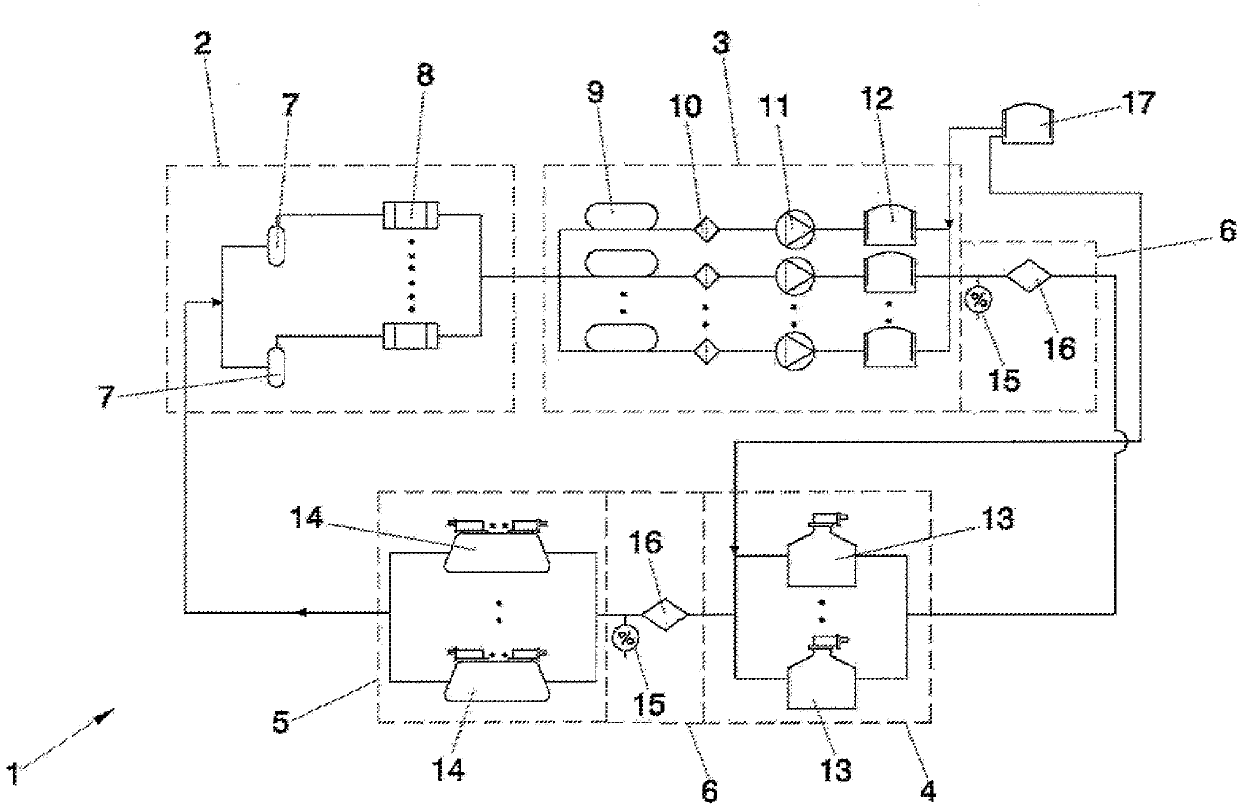

[0027] Such as figure 1 As indicated, a preferred embodiment of the helium recovery plant ( 1 ) object of the present invention is described below.

[0028] Such as figure 1 As shown in , the helium recovery device (1) consists of five modules: recovery module (2), pressurized storage module (3), purification module (4), liquefaction module (5), and distribution module (6) .

[0029]In this recovery module (2), gas is recovered from a series of scientific or medical installations (7) by means of a recovery module (2) ensuring maximum and minimum pressure conditions of the scientific or medical installation (7), such that such installations ( 7) Independently of other modules (3, 4, 5, 6) and ensure lossless recovery. The recovery module (2) includes electronic pressure sensors as well as safety and shut-off valves to evacuate excess helium in case of excessive and unforeseen evaporation in the unit (7).

[0030] Once recovered through the recovery module (2), the helium of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com