Vertical and horizontal compound excitation type piezoelectric energy harvester

A technology of piezoelectric energy harvesting and compound excitation, which is applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of limited freedom and unsuitable multi-directional vibration energy recovery and other issues to achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

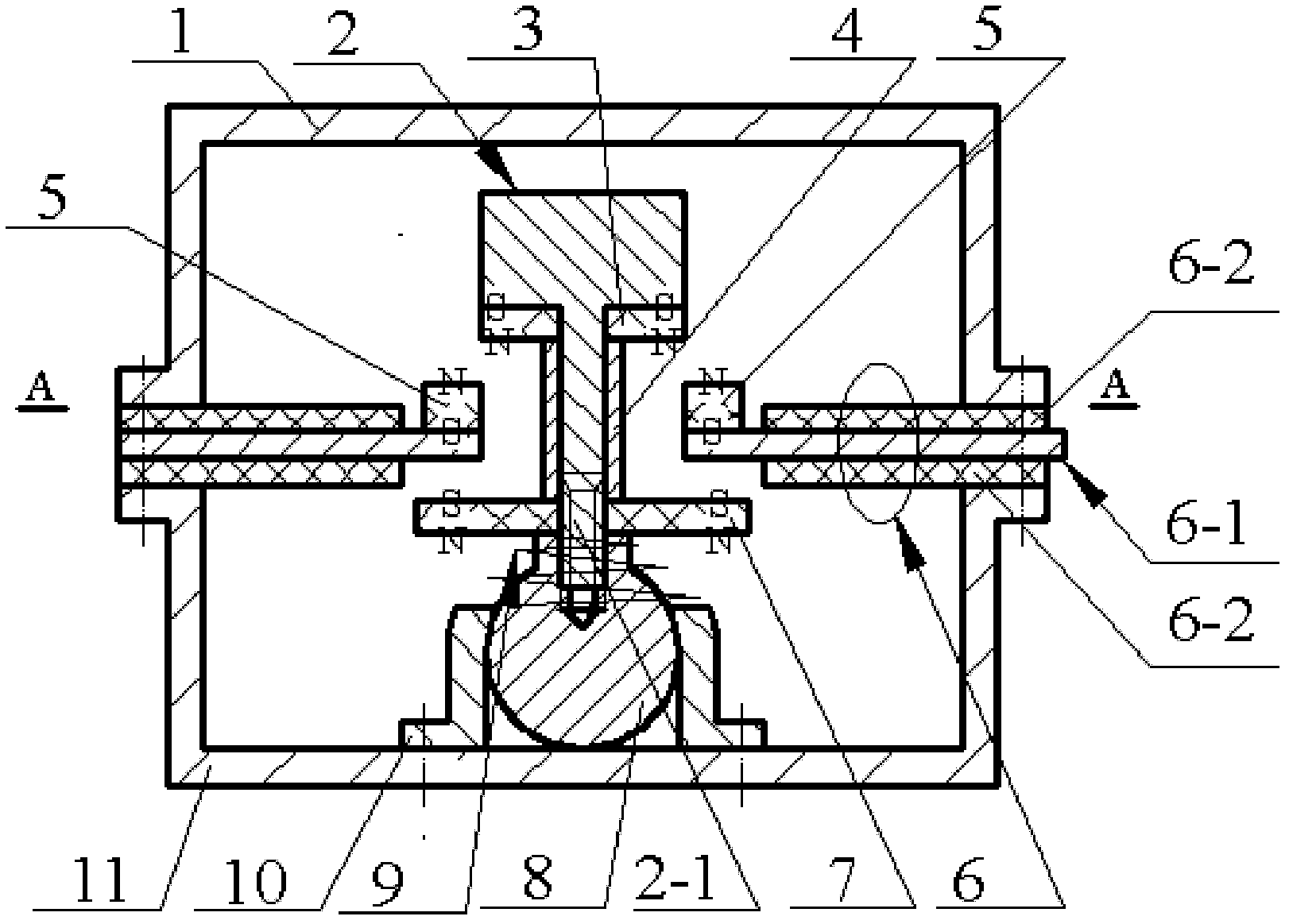

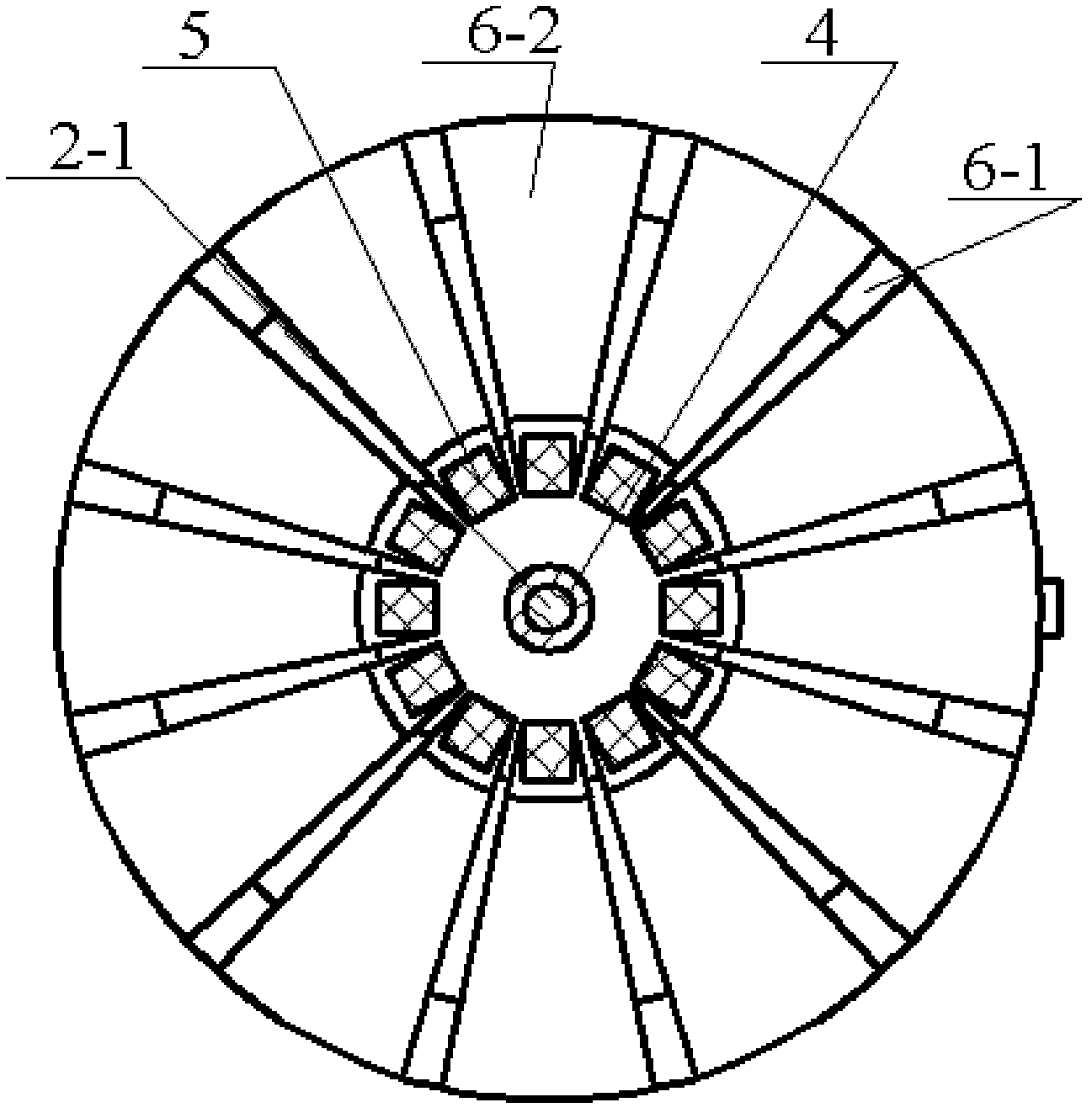

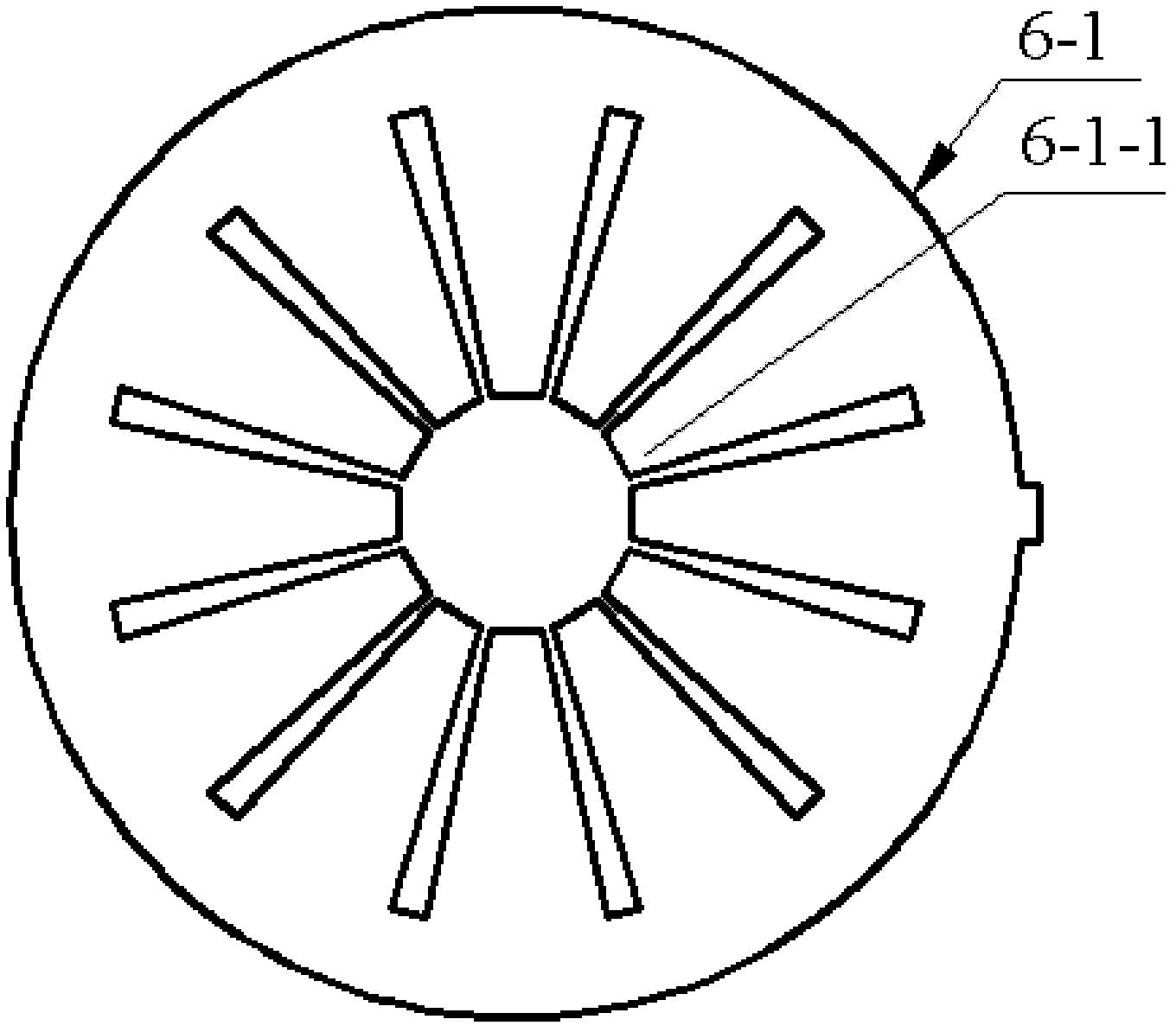

[0013] like figure 1 , figure 2 , image 3 As shown, the upper casing 1 and the lower casing 11 are connected by screws, and a group of piezoelectric vibrators 6 are clamped between the upper casing 1 and the lower casing 11; the piezoelectric vibrators 6 are composed of a metal substrate 6- 1 and the piezoelectric wafer 6-2 are bonded together. The free end of the piezoelectric vibrator 6 is installed with a magnet 5; A ball pin 8 is installed; the ball pin 8 is connected with the inertia block 2 through the screw 2-1 on the inertia block 2; the screw 2-1 is sleeved with a first annular magnet 3, a sleeve 4 and a Two ring magnets 7, the first ring magnet 3, the sleeve 4 and the second ring magnet 7 are crimped between the ball pin 8 and the inertia block 2; the ball pin 8 is covered with a spring 9, so The spring 9 is crimped between the ball pin sleeve 10 and the second annular magnet 7; the magnet 5 installed on the piezoelectric vibrator 6 and the first annular magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com