String offset preventing mechanical axis

The technology of a mechanical shaft and a peg is applied in the field of anti-running mechanical shafts, which can solve the problems of the rotation speed and amplitude of the peg, the depth of the peg hole, and difficulty in tuning, and achieves low cost and simple structure. , the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

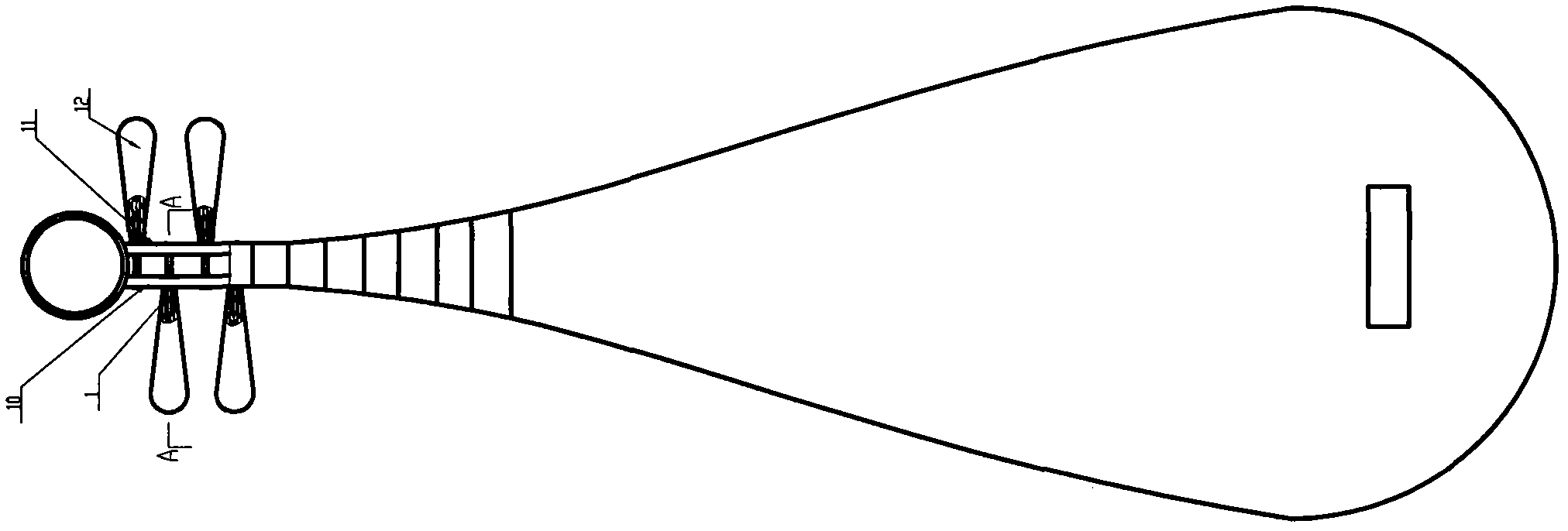

[0015] Embodiment 1, as figure 1 , figure 2 As shown, an anti-running string mechanical shaft is composed of a damping structure and a locking mechanism. Through the damping mechanism and locking mechanism arranged on the left and right plates of the string groove. The damping mechanism is arranged on the left plate (10) of the string groove of the musical instrument, and the damping mechanism is composed of a damping plate (3), a spring seat (2), a tuner sealing plate (4), and a tuner shell (5). The damping mechanism uses elastic force to press the damping plate (3) to meet the large frictional force required for tuning. The annular spring seat (2) is provided with a spring (9). The damping mechanism is made of metal and anti-aging and wear-resistant The assembly composed of materials is not affected by the change of weather temperature and humidity. The tuner shell (5) is arranged outside the damping plate (3), and the tuner shell (5) is fixed on the left plate (10) of th...

Embodiment 2

[0016] Embodiment 2, as image 3 As shown, when installing in reverse, the spring seat (2) is welded on the damping mechanism as the tuner sealing plate (4), and the spring seat (2) is welded on the tuner shell (5), and the working principle is the same. The damping mechanism uses the elastic force of the spring (9) to press the damping plate (3). Since the damping plate (3) is made of anti-aging and wear-resistant materials, the friction force required for tuning can be satisfied when the spring pressure is large. When turning the peg (1) to make the strings reach the standard pitch, you can tighten the locking screw (7). During the tightening process, the locking chuck (8) is squeezed, and the locking chuck (8) also has a taper, and the taper is the same as that of the locking screw (7), and the locking chuck (8) has a cross-shaped groove, so that The locking chuck (8) holds the peg (1) tightly, so as to achieve the purpose of locking. The piano shaft can be loosened by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com