Extensible multifunctional control system

A control system and multi-functional technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of equipment manufacturers' high cost pressure, signal interference, safety hazards, etc., and achieve the workload of debugging and maintenance. The effect of reducing the reduction, improving the data processing capacity, and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

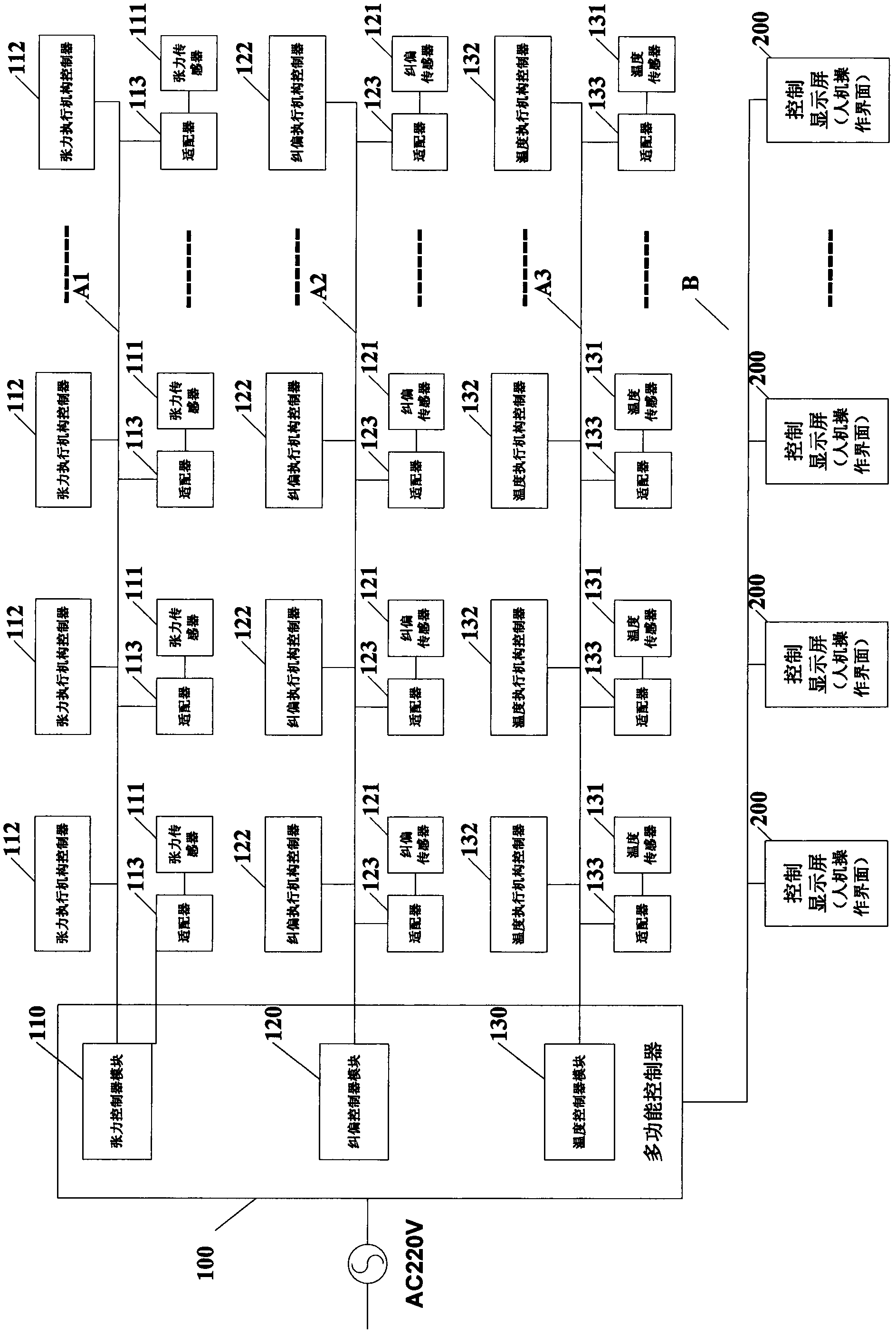

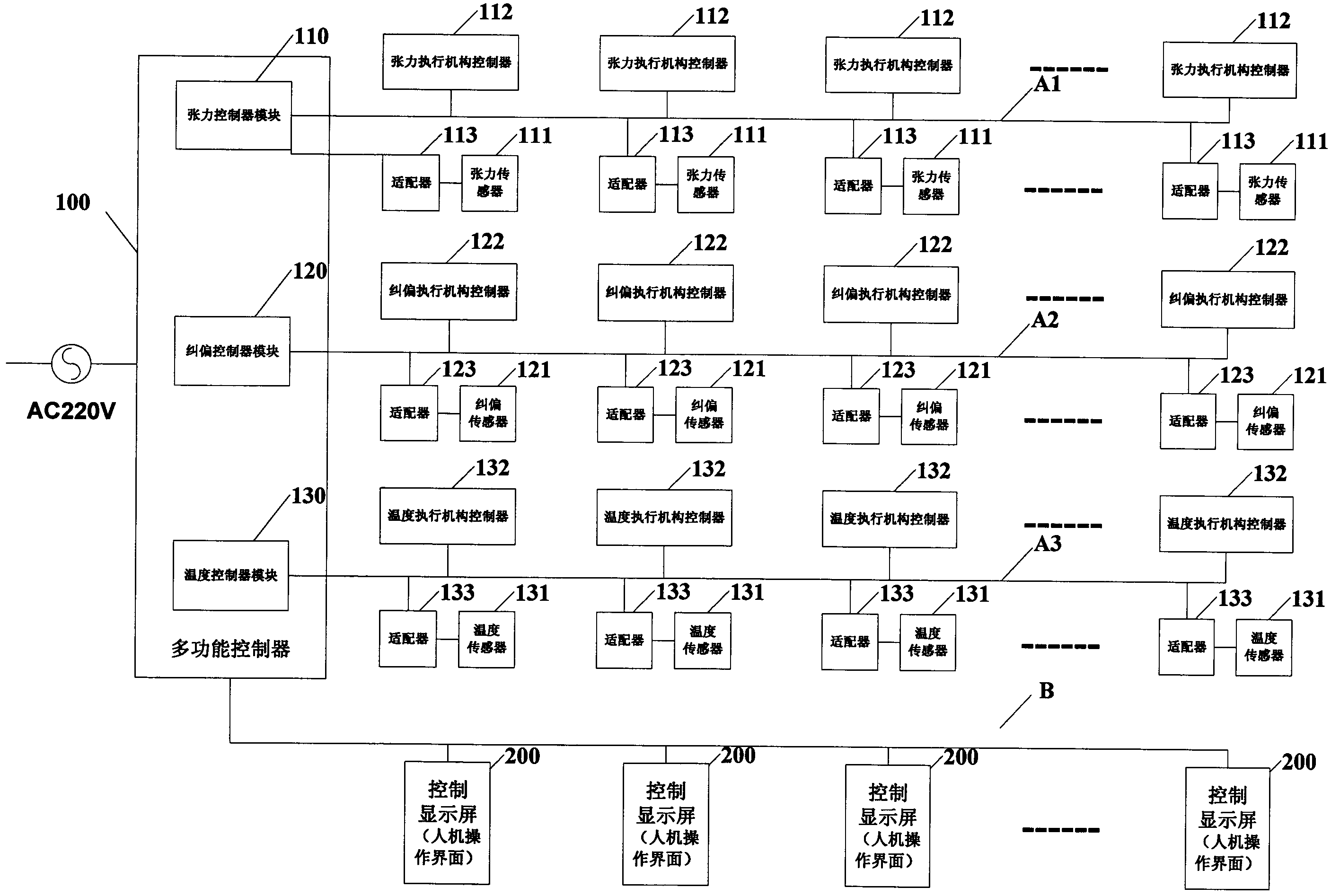

[0021] Such as figure 1 As shown, the scalable multifunctional control system described in the embodiment of the present invention includes a multifunctional controller 100 composed of a tension controller module 110, a deviation correction controller module 120 and a temperature controller module 130, and several tension Sensor 111 , deflection correction sensor 121 and temperature sensor 131 , and several tension actuator controllers 112 , deflection correction actuator controllers 122 and temperature actuator controllers 132 . Wherein, the processor of the multi-function controller 100 in the system adopts an ARM M4 processor with a main frequency of 150 MHz. In the system, each tension sensor 111 , deflection correction sensor 121 and tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com