Variable volume trace gas sampling valve

A technology of trace gas and sampling valve, which is applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as inability to be applied, and achieve the effects of simple structure and method, accurate quantification, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

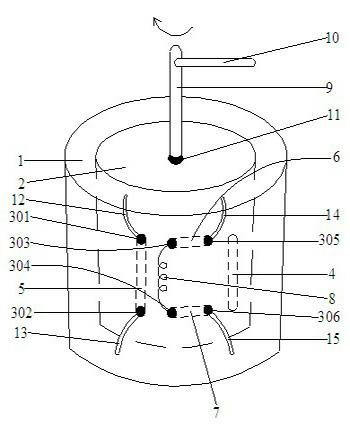

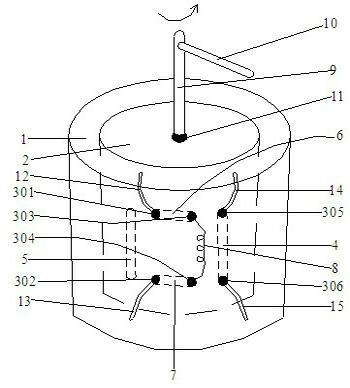

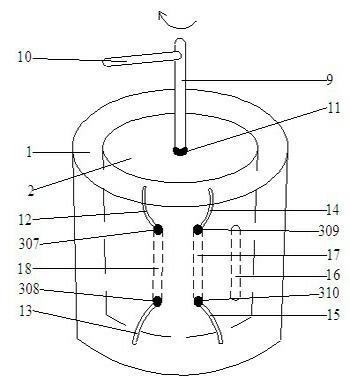

[0021] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0022] Such as Figure 1~4 A variable-volume trace gas sampling valve shown includes a fixed shell and a rotating inner core. The rotating inner core 2 is set in the fixed shell 1, and the upper center of the rotating inner core is fixed by a thread 11 to a vertical rod 9. The handle 10 is fixed on the vertical rod, and the rotating core is rotated 90 degrees in the fixed shell through the handle. The fixed shell is made of stainless steel, and the rotating core is made of resin with sealing performance. The vertical rod in the center is a stainless steel rod . There are ten holes on the side of the fixed shell, which are respectively composed of six-hole structures and four-hole structures corresponding to the positions. The side of the rotating core corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com