Creep test device and test method thereof

A testing device and creep technology, applied in measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve problems such as difficulty in maintaining constant pressure, low precision of tensile displacement, waste of manpower and energy, etc. , to achieve the effect of small fluctuation, stable load and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

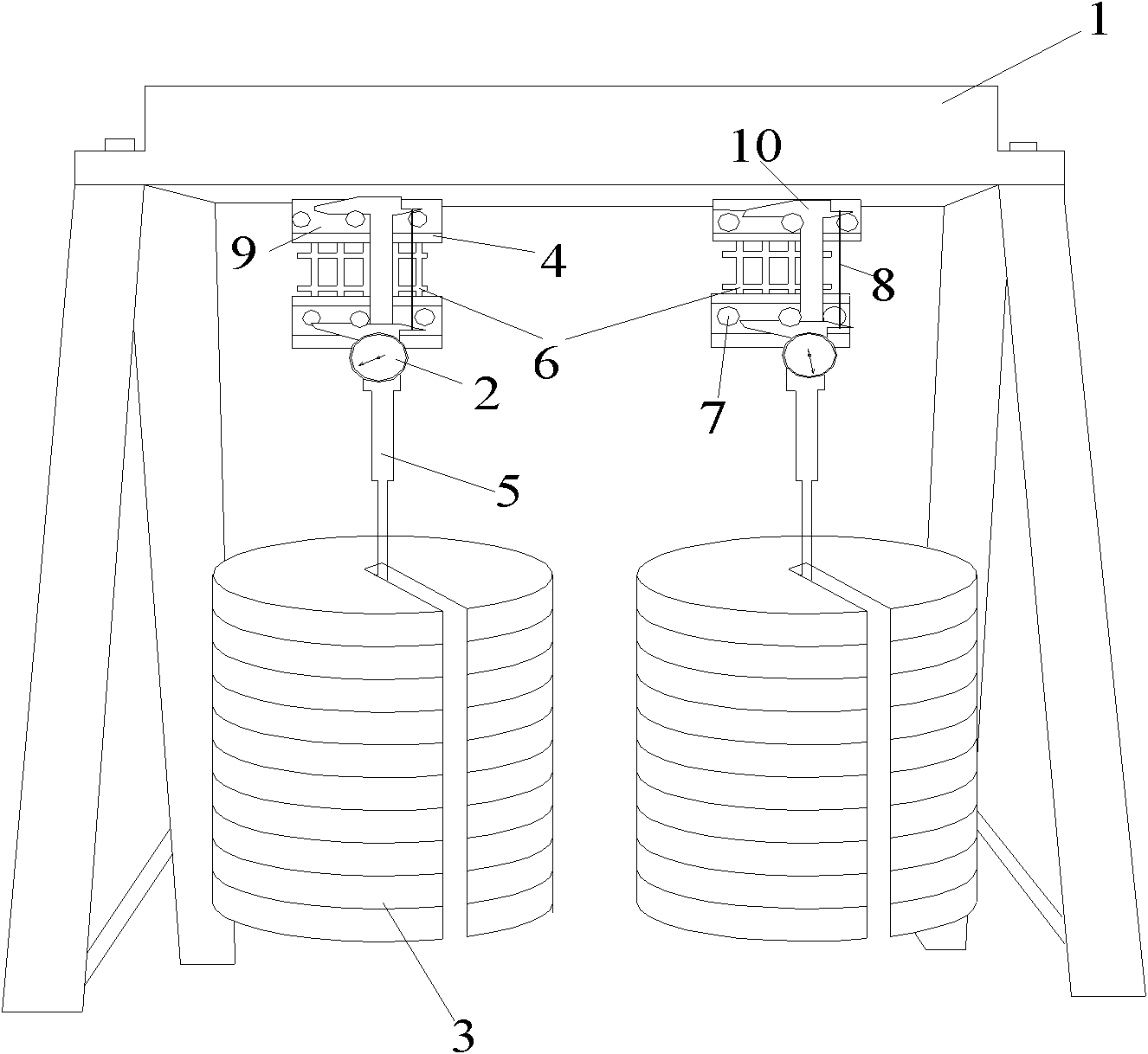

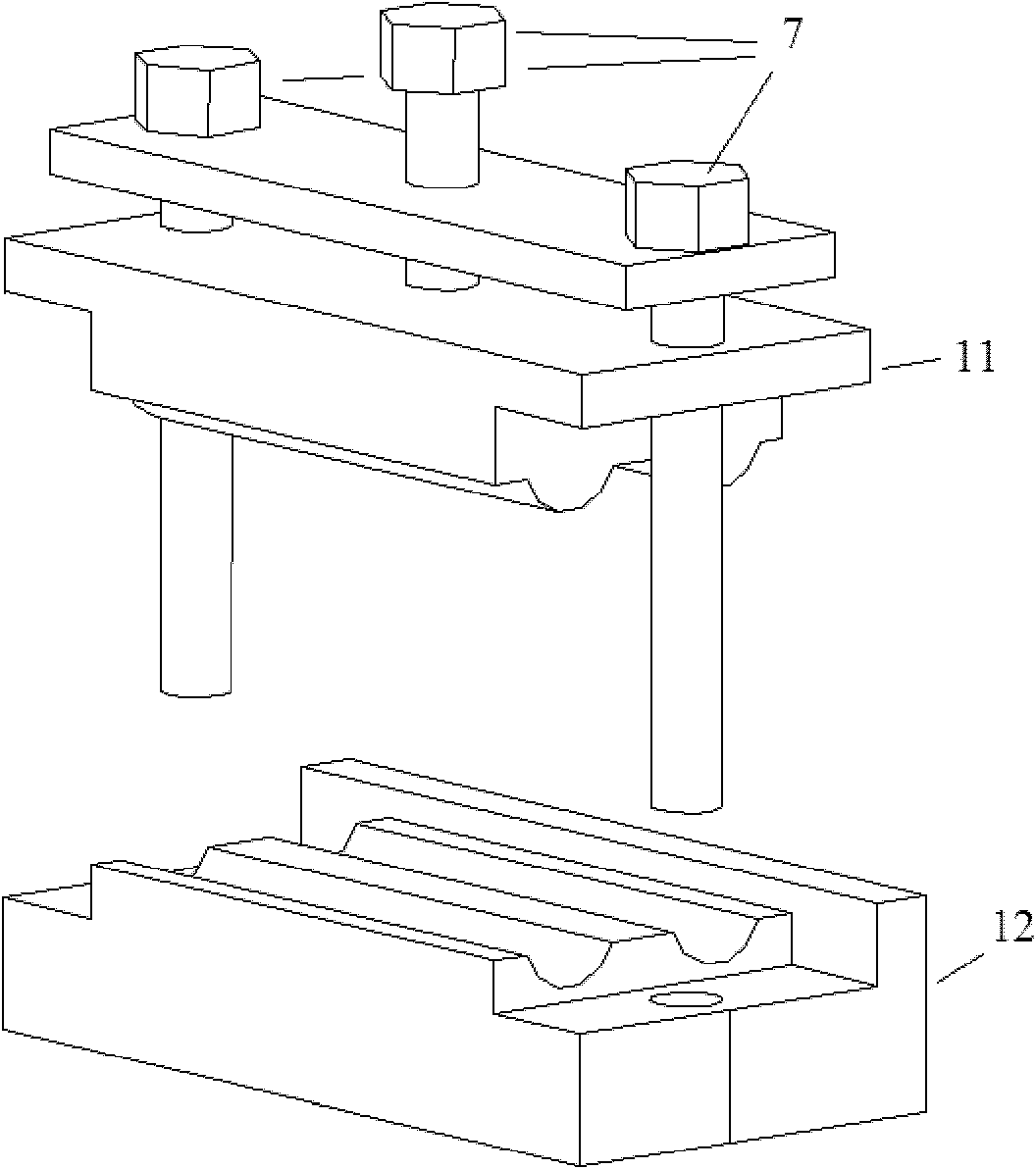

[0032] Such as figure 1 , 2 As shown, a creep test device includes a test bench with a tetrapod 1 structure, and the four legs of the tetrapod 1 are connected by beams. A fixing system 4 for fixing the geogrid test sample 6 is arranged on the lower side of the top of the test bench, a vernier caliper 2 with a watch is arranged on the fixing system 4, and a loading device is connected to the lower part of the fixing system 4. The fixing system 4 includes two sets of upper and lower relative upper and lower clamps 11, 12 connected by screws 7, on the corresponding surfaces of the two relative upper and lower clamps, wherein the lower surface of the upper clamp 11 is provided with two protrusions, The upper surface of the lower fixture 12 is provided with two grooves corresponding to the protrusions.

[0033] The two measuring claws 10 of the vernier ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com