Pressure-differential type aluminum producing device for aluminum alloy melting furnace

A technology for melting furnaces and aluminum alloys, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of unsealed aluminum outlets, danger, and leakage of aluminum liquid, so as to save aluminum working time and save time , Improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

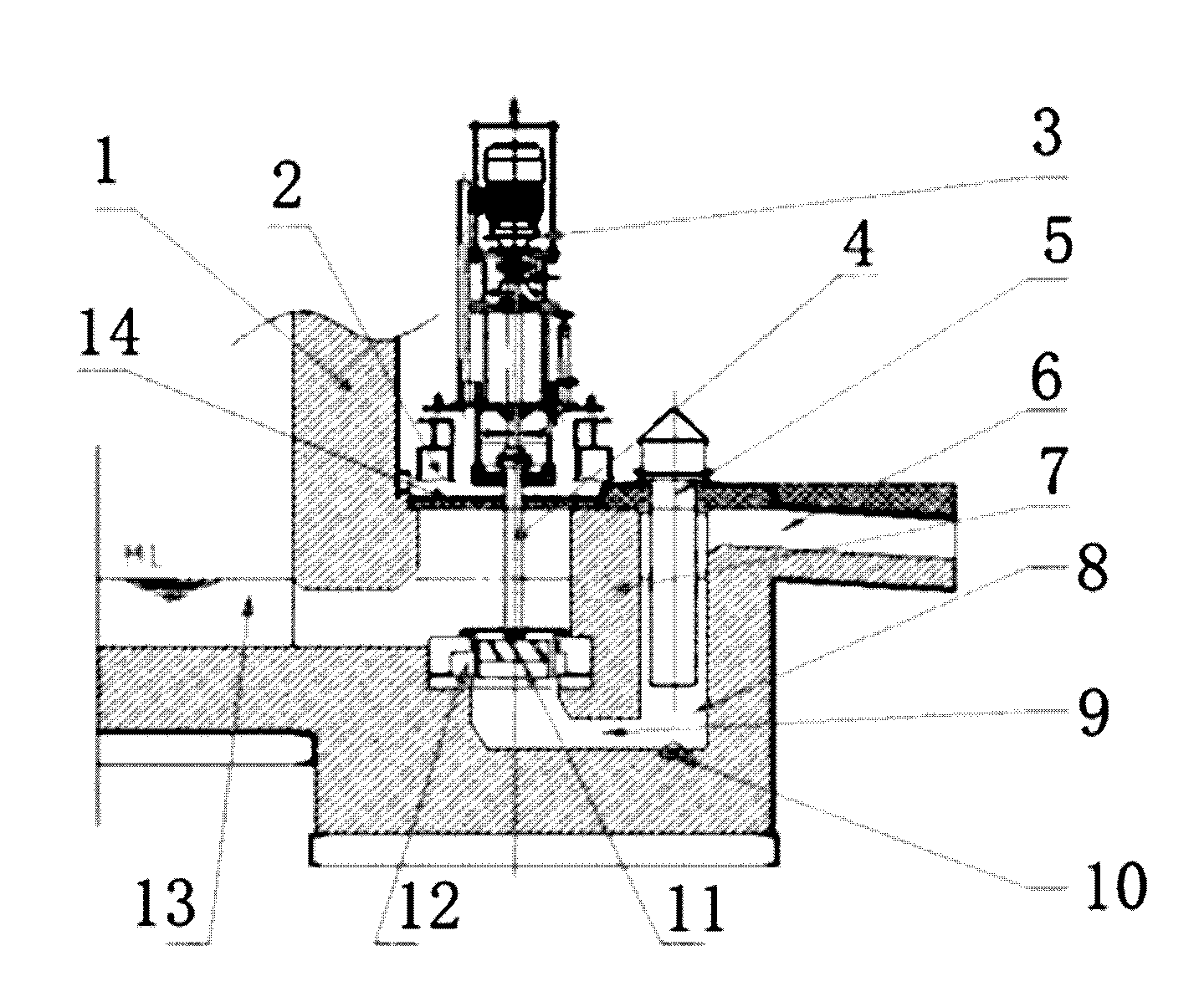

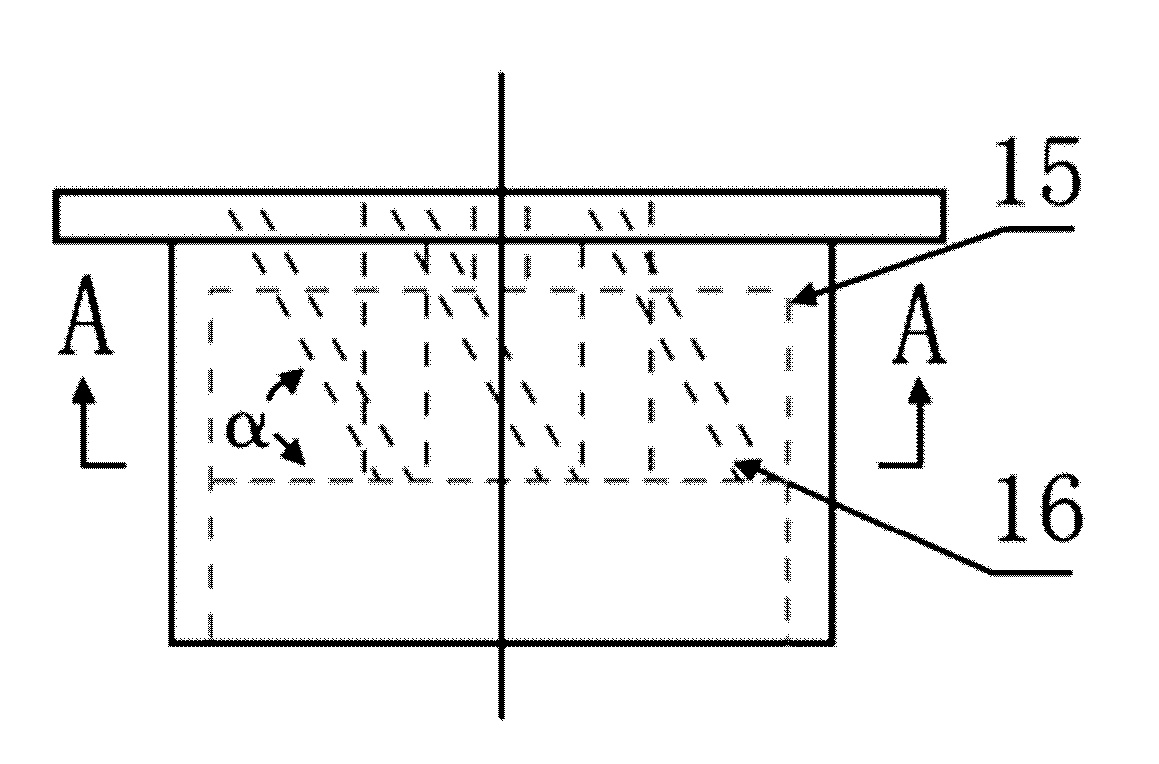

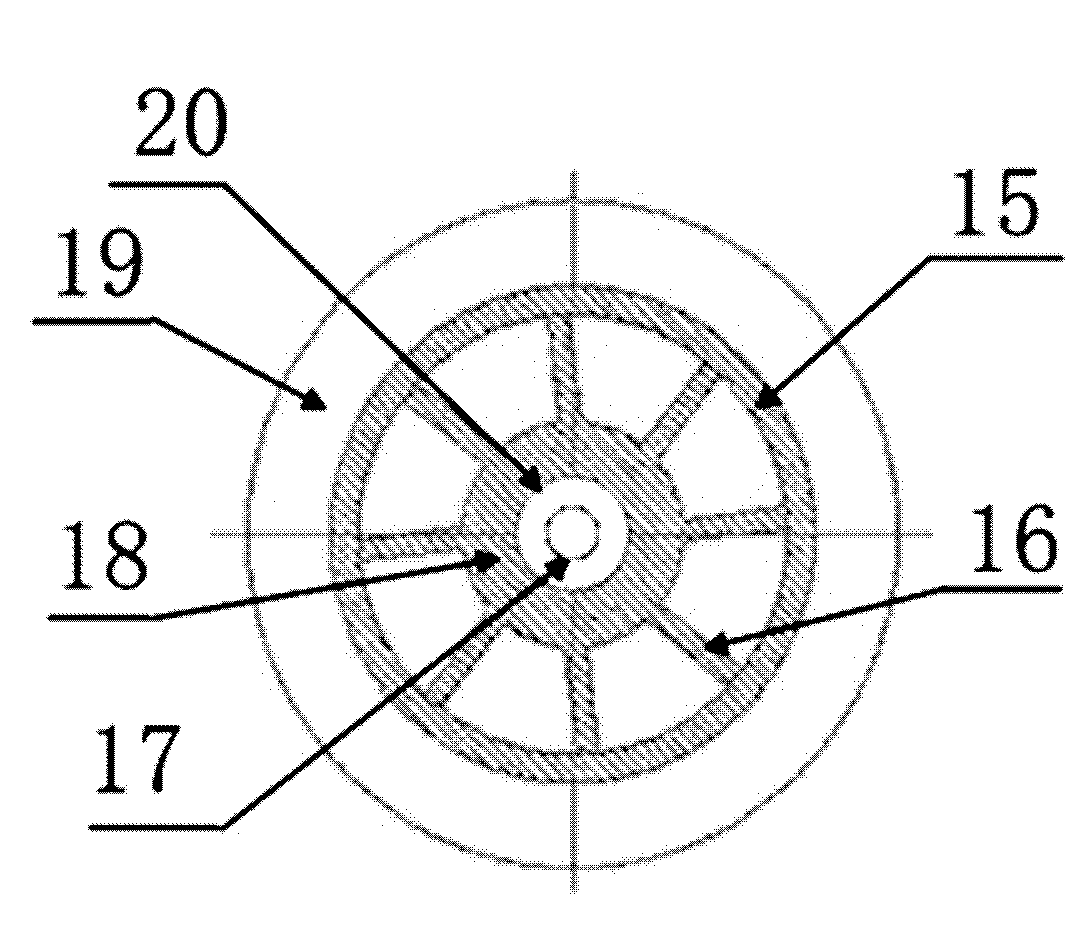

[0018] The aluminum outlet designed by the present invention is as attached figure 1 shown in the attached figure 1 Among them, 1 is the furnace wall, 2 is the fixed frame, 3 is the motor and deceleration system, 4 is the impeller shaft, 5 is the heating heater, 6 is the aluminum outlet tank, 7 is the partition wall, 8 is the liquid outlet chamber, and 9 is the aluminum liquid Horizontal channel, 10 is a discharge port, 11 is an impeller, 12 is an impeller vortex, 13 is an internal molten pool, and 14 is a cover plate. Depend on figure 1 It can be seen that the device is located outside the furnace wall of the aluminum alloy melting furnace equipment, and an impeller vortex 12 connected with the molten pool inside the aluminum alloy melting furnace body is designed. The bottom surface of the impeller vortex 12 is slightly lower than the bottom surface of the molten pool inside the furnace body , the impeller vortex 12 is placed with the impeller 11 driven by the impeller sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com