Bottom driving mechanism of oxygen inclined blown rotating converter

A driving mechanism and oblique blowing technology, applied in the field of smelting furnaces, can solve the problems of spare parts (short service life of the rotary wheel, cumbersome debugging of the driving system, difficult speed, etc.), to reduce energy consumption, simplify installation and debugging, and improve coaxiality The effect of request reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

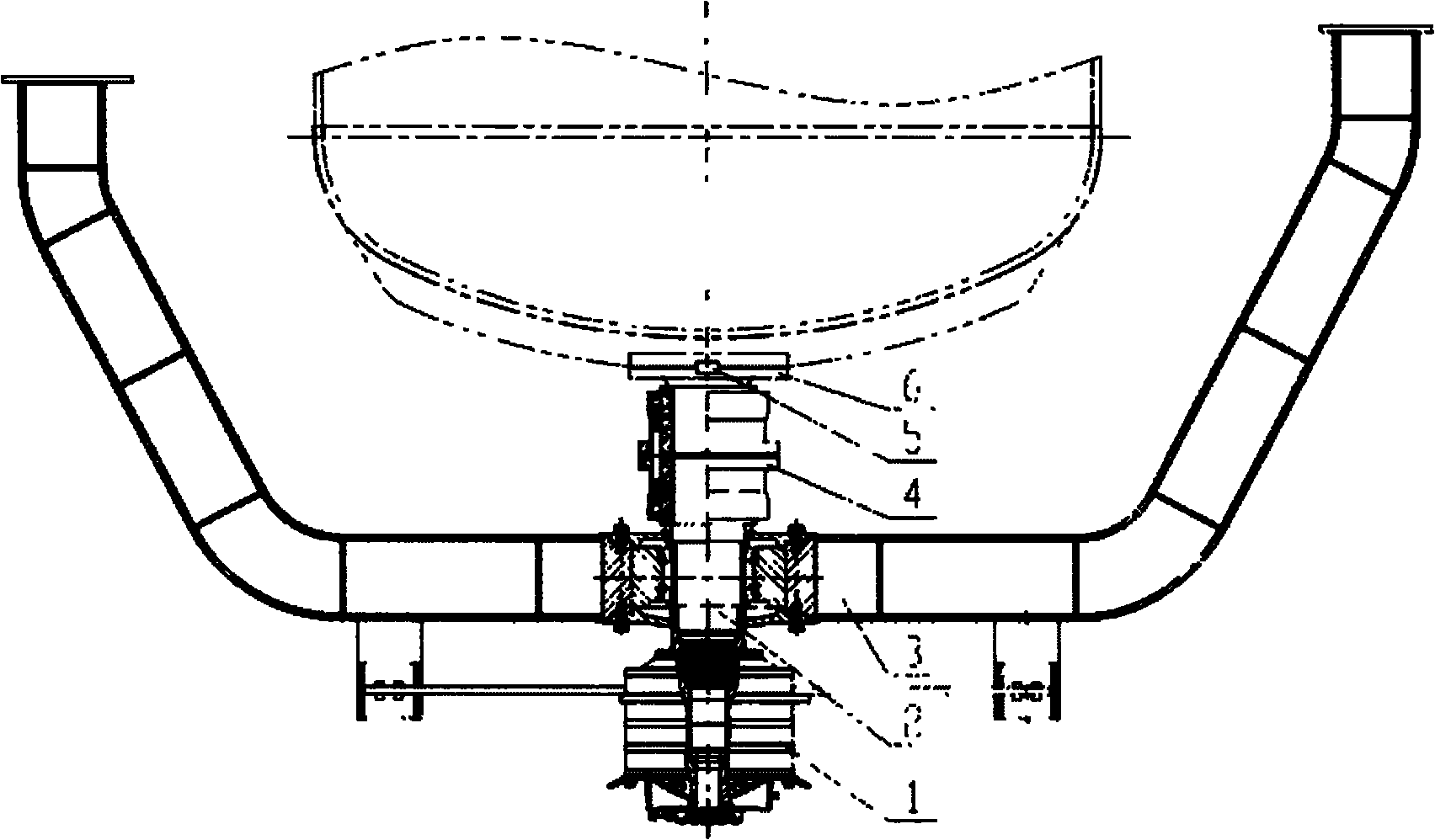

[0013] Such as figure 1 As shown, a bottom driving mechanism of an oxygen oblique-blown rotary converter includes a hydraulic motor 1 , a transmission shaft 2 , a pocket beam 3 , a drum-shaped gear coupling 4 and a connecting shaft 6 . The transmission shaft 2 passes through and is fixed on the pocket beam 3, one end of which is connected with the hydraulic motor 1, and the other end is connected with the drum-shaped gear coupling 4, and the drum-shaped gear coupling 4 is connected to the furnace through the connecting shaft 6. The body is connected; the hydraulic motor 1 is externally connected to the hydraulic station; the connection between the connecting shaft 6 and the furnace body is provided with an end face key 5 .

[0014] During on-site installation, the furnace body is tilted to the position where the bottom of the furnace faces the sky. First, the end key 5 and the connecting shaft 6 are connected to the bottom of the furnace body, and then the drum-shaped tooth co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com