Coal loosening device

A coal loosening device and coal loosening technology, applied in the direction of combustion method, block/powder supply/distribution, combustion equipment, etc., can solve the problems of poor combustion, production impact, low temperature, etc., and achieve safe and reliable use, easy installation Convenience and simple effects

Inactive Publication Date: 2012-07-18

吴舒克

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the raw coal meets the coal gate, it is compressed by the force of the opposite direction of the coal gate. Therefore, the raw coal entering the furnace has poor ventilation and poor combustion, and black slag is easy to appear, resulting in waste of raw coal.

Moreover, the combustion is not good, and the temperature is not high, which will affect the production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

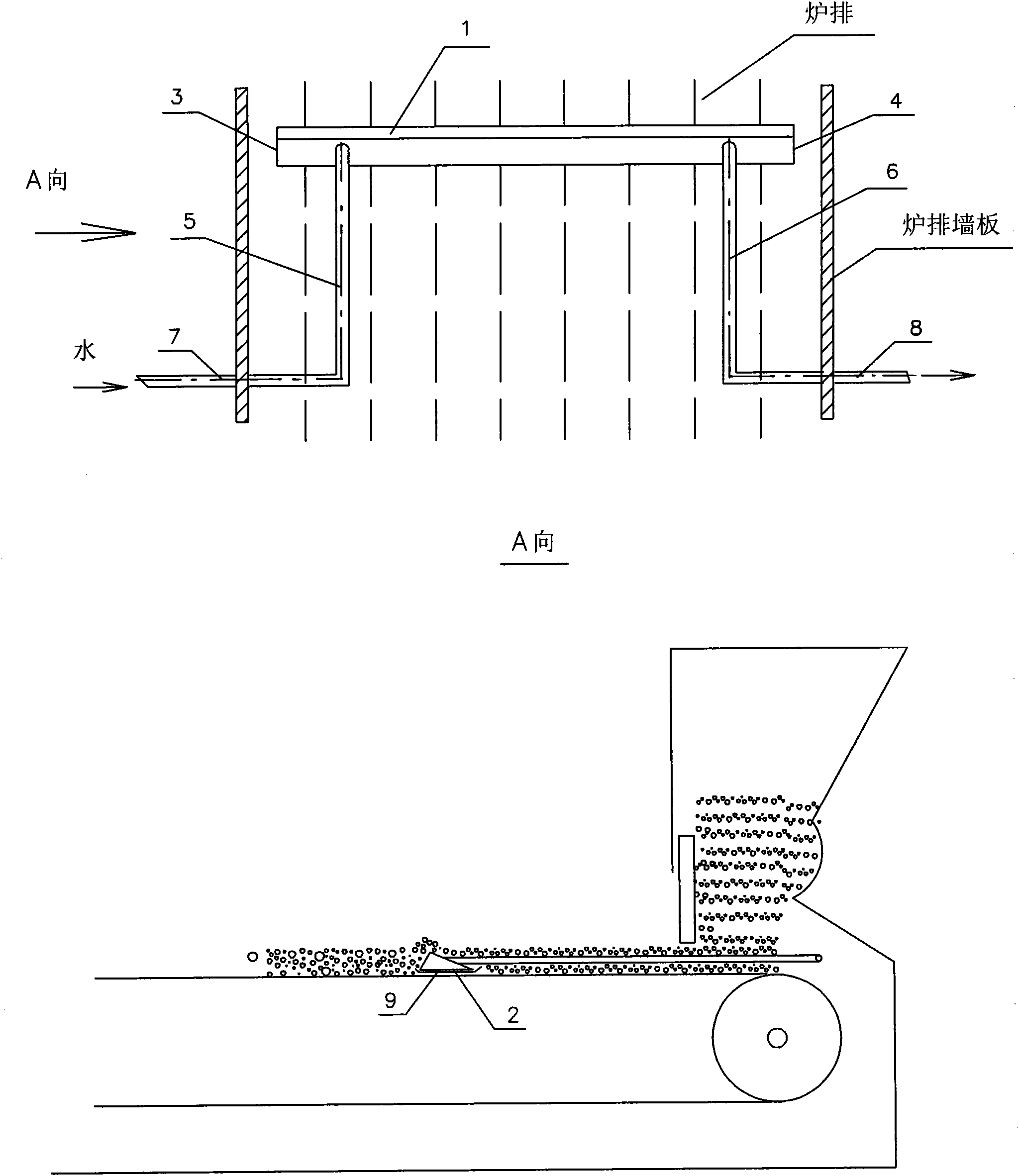

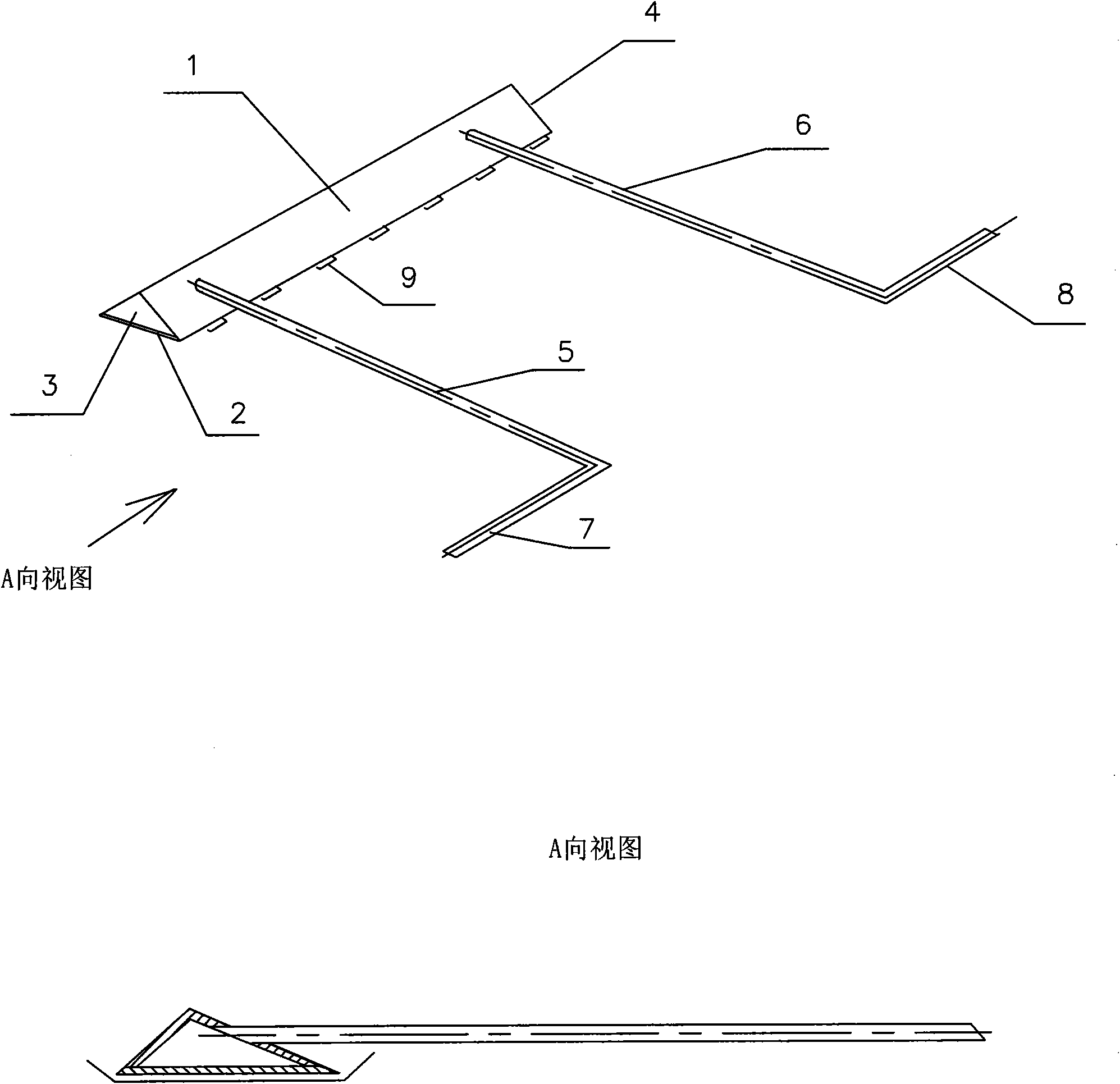

[0010] First put the coal loosening device flatly on the grate surface, then connect the connecting pipes (7), (8), and finally connect the pipes with cooling water. During operation, as long as the cooling water is turned on, it can be used normally.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a device, which is mounted on a grate below a boiler coal bucket, and used for loosening raw coal by the aid of movement power of the chain grate and the raw coal. The scheme of the device mainly includes that the length of the device is controlled to be smaller than the width of the whole grate by the size of a grate bar by hot-rolled inequilateral angle iron (1). Two right-angle sides of the hot-rolled inequilateral angle iron are sealed by a steel plate (2) with a moderate width, two ends of the hot-rolled inequilateral angle iron are also sealed by steel plates (3) and (4), a stereoscopic triangle is formed, a long side of the stereoscopic triangle is downwardly placed on the grate, two pipes (5) and (6) of the same length are parallelly welded on the surface of the triangle with the long right-angle sides, one end of each pipe is provided with a screw socket, other pipelines (7) and (8) are connected onto a left side wallboard and a right side wallboard in front of the grate respectively through screw sockets, cooling water is led into the pipelines, and wear-resistant sections are welded below a bottom plate of the coal loosening device at intervals through flat iron (9), so that wear of the coal loosening device due to the grate is relieved.

Description

technical field [0001] The invention relates to a boiler equipment, which is installed on the fire grate under the coal hopper of the boiler, and relies on the coal seam to move on the fire grate chain to loosen the coal seam, so that the raw coal can enter the furnace for more complete and thorough combustion. technical background [0002] At present, most chain boilers are not equipped with a coal loosening device in operation. The raw coal must pass through the coal gate before entering the furnace from the coal hopper. The role of the coal gate is to fix the thickness of the coal seam and control the amount of coal input. When the raw coal meets the coal gate, the raw coal is compressed by the opposite force of the coal gate. Therefore, the raw coal entering the furnace has poor ventilation and poor combustion, and black slag is easy to appear, resulting in waste of raw coal. Moreover, the combustion is not good, and the temperature is not high, which affects production....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23K3/08

Inventor 吴舒克

Owner 吴舒克

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com