On-line leakage detecting method of gas cutting-off system

A gas and electric butterfly valve technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of gas poisoning of staff, high labor intensity of workers, gas explosion, etc., and achieve accurate and timely detection and judgment, reduce The labor intensity of workers and the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

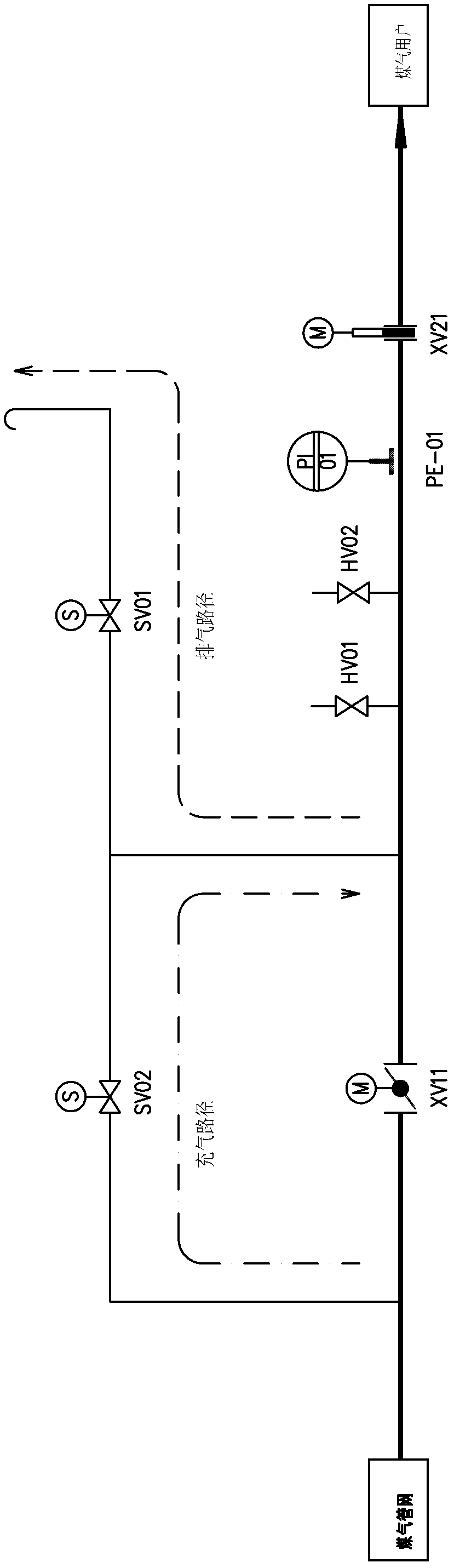

[0024] figure 1 It is the gas path connection diagram of the present invention, including the gas pipeline between the gas pipeline network and the gas user, and the electric butterfly valve XV11, the analysis and sampling valve HV01, the purge valve HV02, and the pressure switch arranged in sequence on the gas pipeline according to the gas flow direction PI01 and electric glasses valve XV21 also include bypass solenoid valve SV02 and vent solenoid valve SV01, wherein the bypass solenoid valve SV02 is connected in parallel with the electric butterfly valve XV11 through a pipeline, and one end of the vent solenoid valve SV01 is connected to the electric butterfly valve XV11 and the analysis valve through a pipe. On the pipeline between the sampling valve HV01, the other end is connected to the atmosphere.

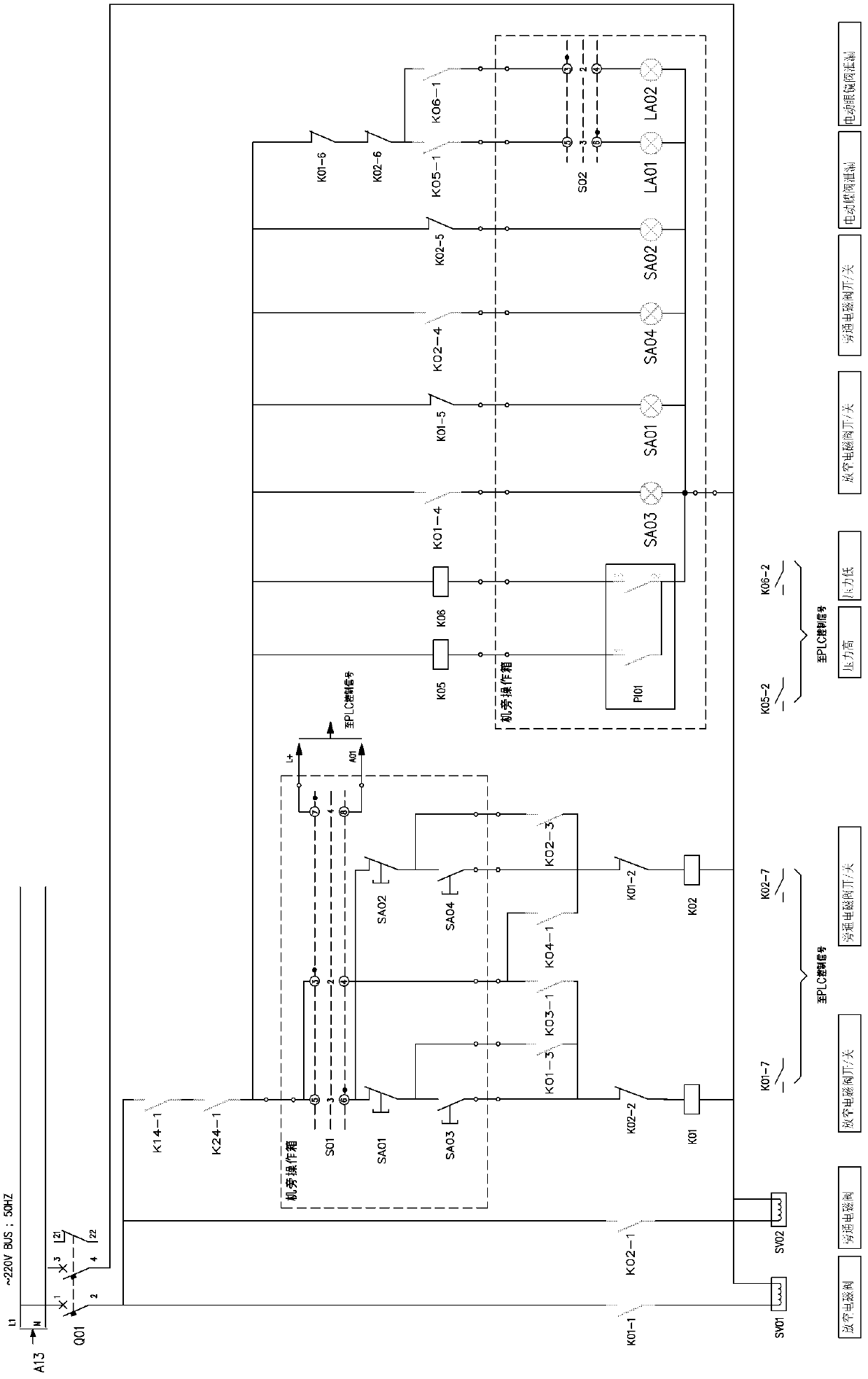

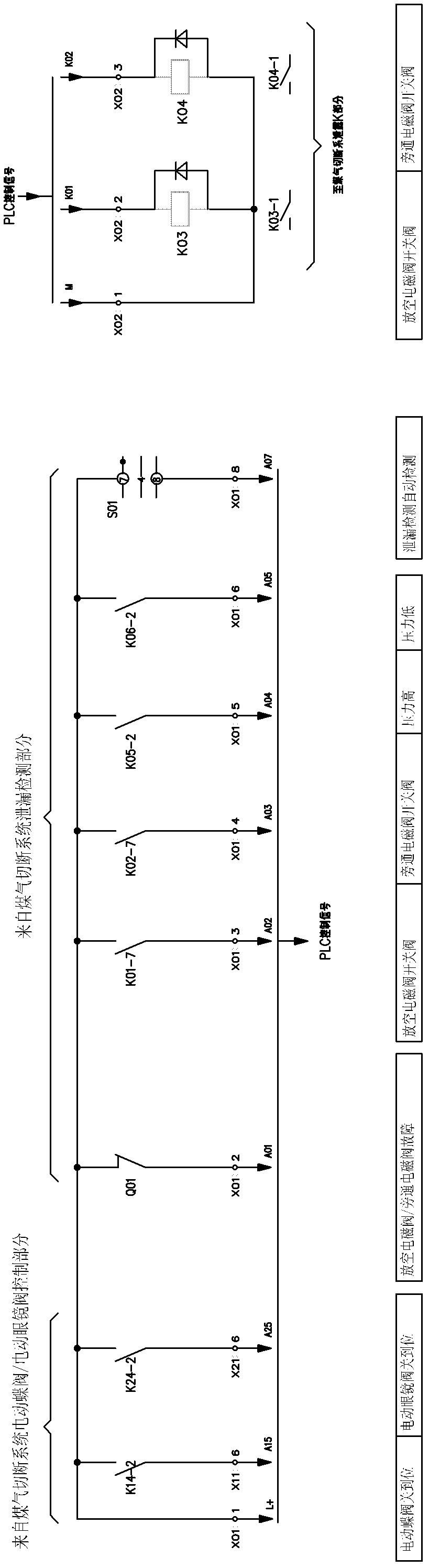

[0025] like figure 2 , image 3 As shown, the pressure switch PI01, the bypass solenoid valve SV02 and the vent solenoid valve SV01 are all controlled by the programmable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com