Side slope anchoring hole drilling construction equipment and side slope anchoring hole drilling construction method

A technology of construction equipment and drilling equipment, which is applied in the direction of drilling equipment and methods, drilling equipment, directional drilling, etc., which can solve the problems of high danger for construction personnel, long construction period, and large construction volume, so as to improve construction safety , improve work efficiency, simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

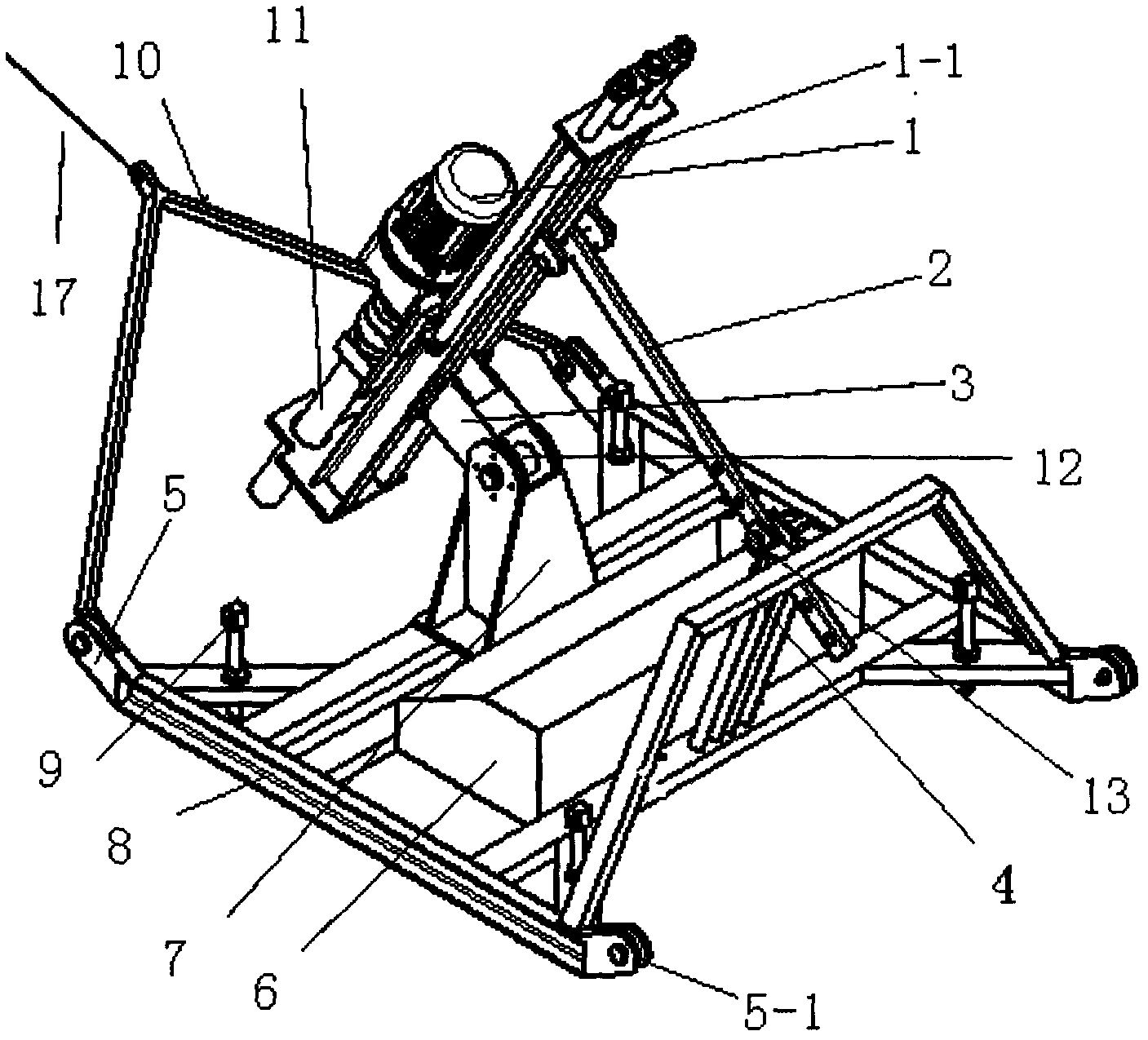

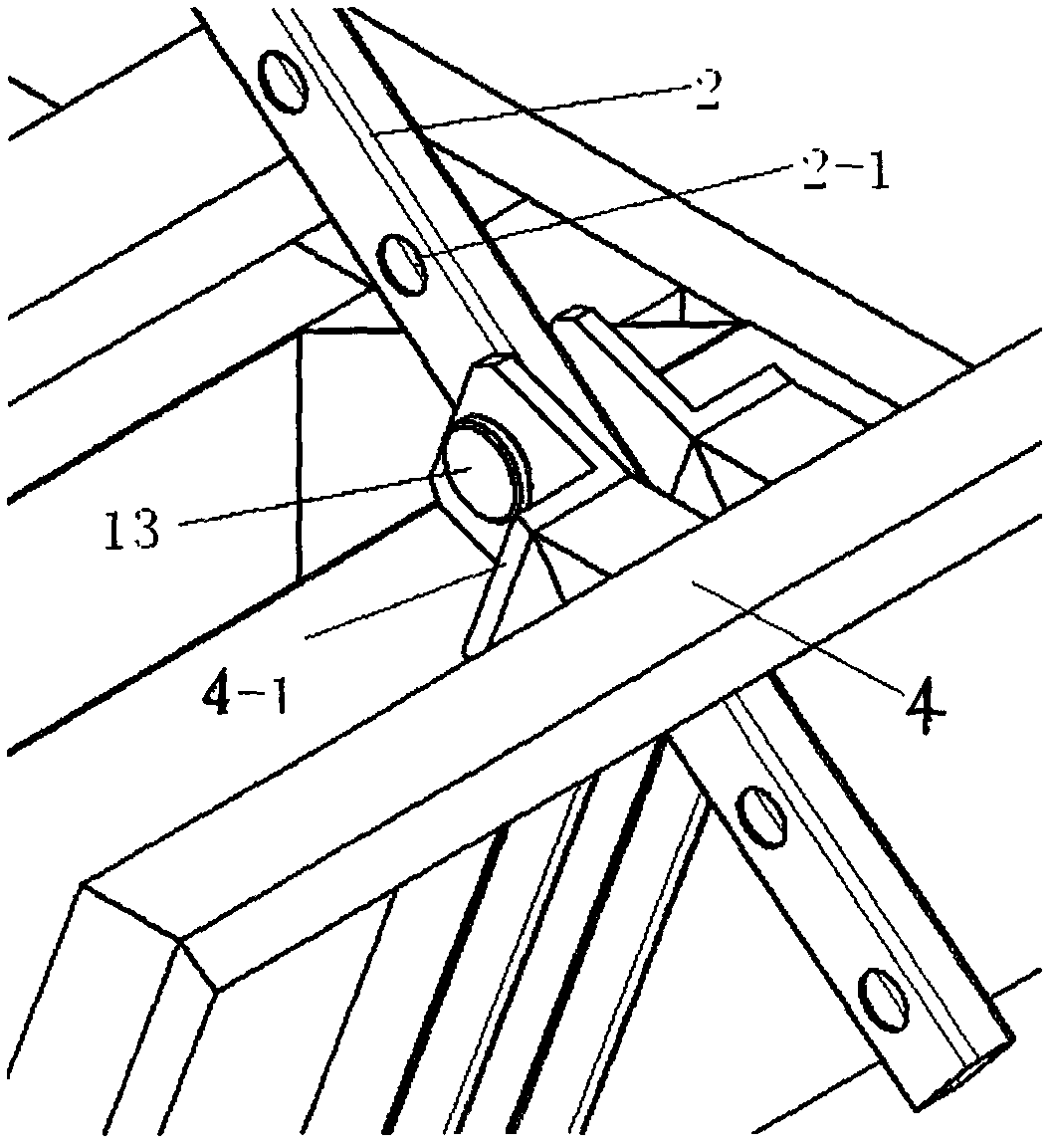

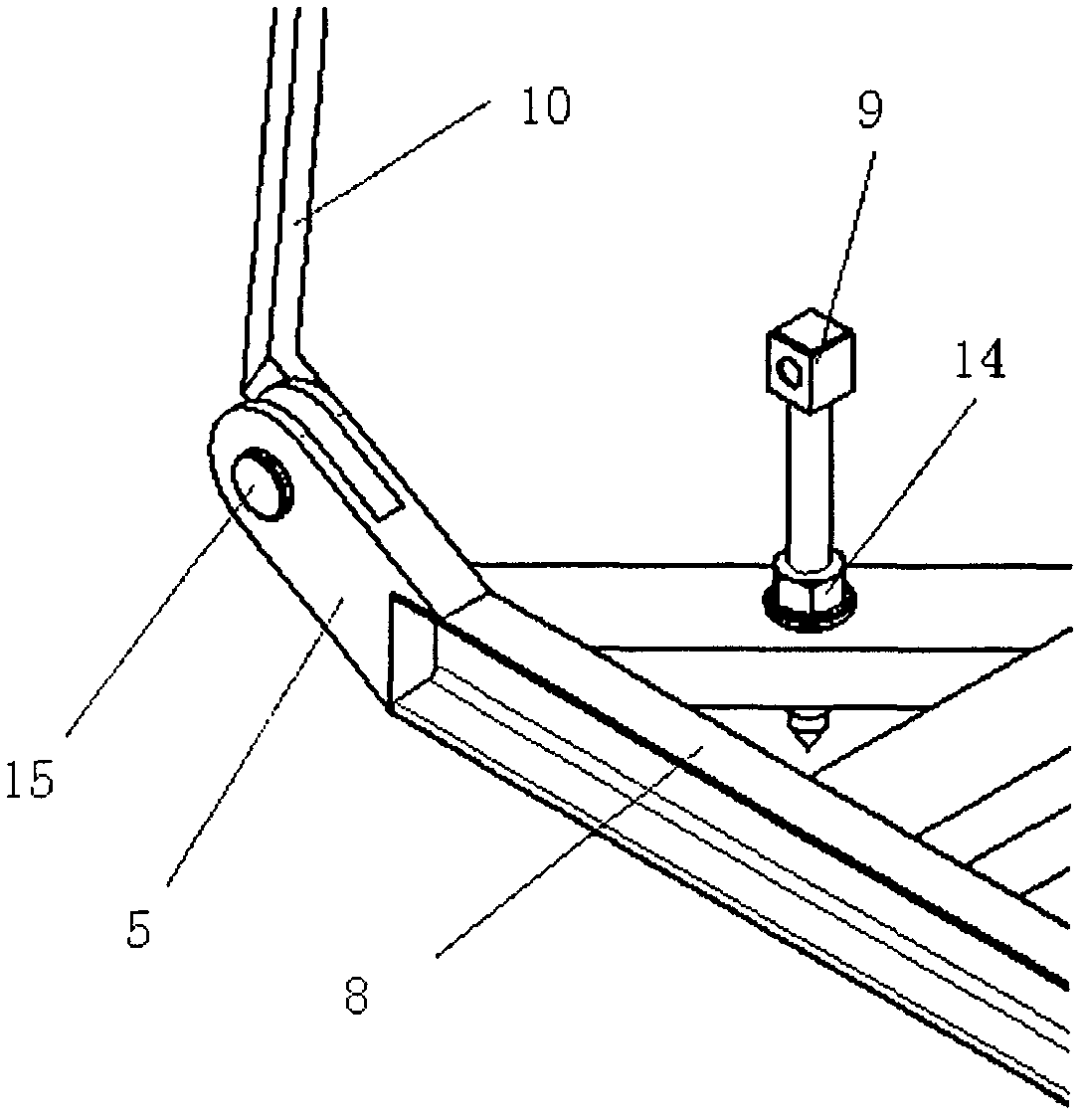

[0026] see figure 1 , figure 2 , the two front skid heads 5 of the front end of the sled frame 8 are hinged with the traction frame 10. One end of the steel cable 17 wound on the winch 16 is tied to the middle part of the traction frame 10 . The lower hinge base 7 is fixed on the middle front part of the frame 8, the upper hinge base 3 is fixed on the lower channel steel frame 1-1 of the drilling machine 1 with the drill rod 11, and the upper hinge base 3 and the lower hinge base 7 pass through the pins. The shaft 12 realizes the hinge connection. Back support 4 is fixed on the afterbody of frame 8. One end of the support rod 2 is supported on the rear portion of the drilling machine 1 channel steel frame in a hinged form. There is a support seat 4-1 containing a support hole 4-2 at the position relative to the support rod 2 on the rear bracket 4 at the rear of the frame, and the pin rod 3 is inserted into a certain positioning hole 2-1 of several positioning holes on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com