Textile dyeing machine

A technology for dyeing machines and fabrics, applied in the field of dyeing machines, which can solve the problems of low dyeing efficiency, inability to meet the needs of open-width fabric dyeing, and high energy consumption of dyeing machines, and achieve a wide range of bath ratios, high flatness, and improved washing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

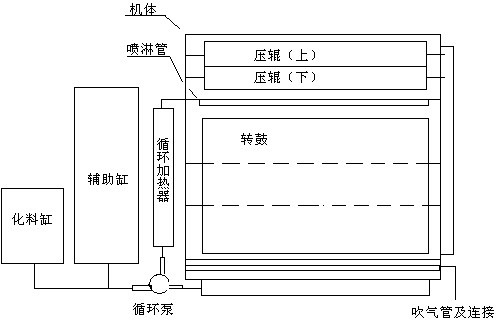

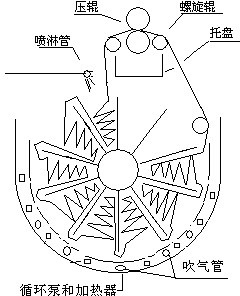

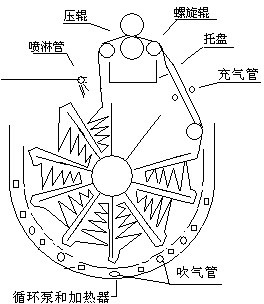

[0020] Such as figure 1 , 2 3. The novel fabric dyeing machine shown in 3 includes a cylindrical dyeing tank, a drum coaxial with the dyeing tank is arranged in the cylindrical dyeing tank, blades are evenly distributed on the drum, and a drum is arranged on the top of the cylindrical dyeing tank. A group of pressure rollers arranged up and down; the invention is also equipped with a dye liquor circulation pipeline, one end of the dye liquor circulation pipeline communicates with the bottom of the dye tank, and the other end communicates with the sprayer above the dye tank, and the dye liquor circulation pipeline is provided with heater and circulation pump.

[0021] An air blowing pipe is also arranged at the lower part of the above-mentioned dyeing tank, and the air blowing pipe is connected with an air source. The air blown out by the air blowing pipe has two functions: one is to increase the relative movement between the fabric and water (or dyeing liquor, washing liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com