Direct twisting machine

A technology of direct twisting machine and frame, applied in spinning machine, continuous winding spinning machine, textile and papermaking, etc., can solve the problems of poor energy saving effect and large current load of machinery and equipment, and achieve obvious energy saving effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

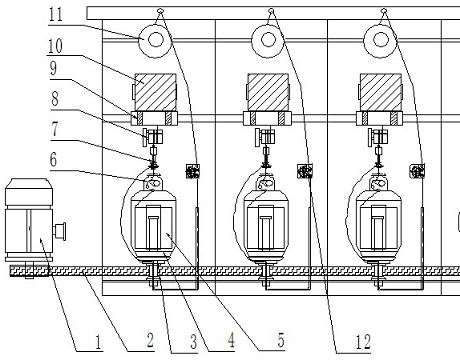

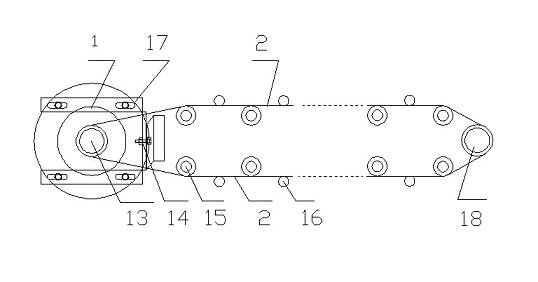

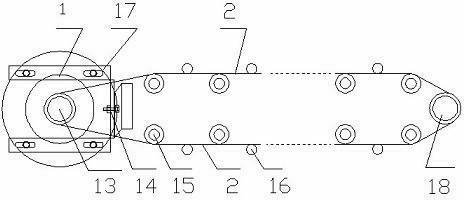

[0019] See attached figure 1 , 2 , the direct twisting machine shown in the embodiment of the present invention is symmetrically installed on the steel plate frame (not shown in the figure) by two rows of spindles 3, each row of spindles has multiple sections, each section has several spindles, and each spindle includes at least Finished package drum 10, winding roller 9, overfeed roller 8, twist leveler 7, spindle pot 4, yarn storage disc installed from top to bottom, and inner yarn package 5 and inner yarn tensioner in the spindle pot 4 6. It also includes an outer yarn creel installed on the steel plate frame, an outer yarn package 11, an outer yarn tensioner 12 and a wire guide tube, and the inner yarn is provided by the spindle yarn placed in the spindle pot 4, The outer yarn is provided by the outer yarn package 11 on the upper part of the machine through the outer yarn creel, passes through the outer yarn tensioner 12, the wire guide tube, enters from the hollow shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com