Vertical annealing furnace for coated superconducting substrate

A technology of vertical annealing furnace and annealing furnace, which is applied to furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of difficult control of annealing quality, large span between the two fulcrums of the base belt, and the rigidity of the sinking strip. Effects of overstretching and sagging, maximizing productivity, reducing experience requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

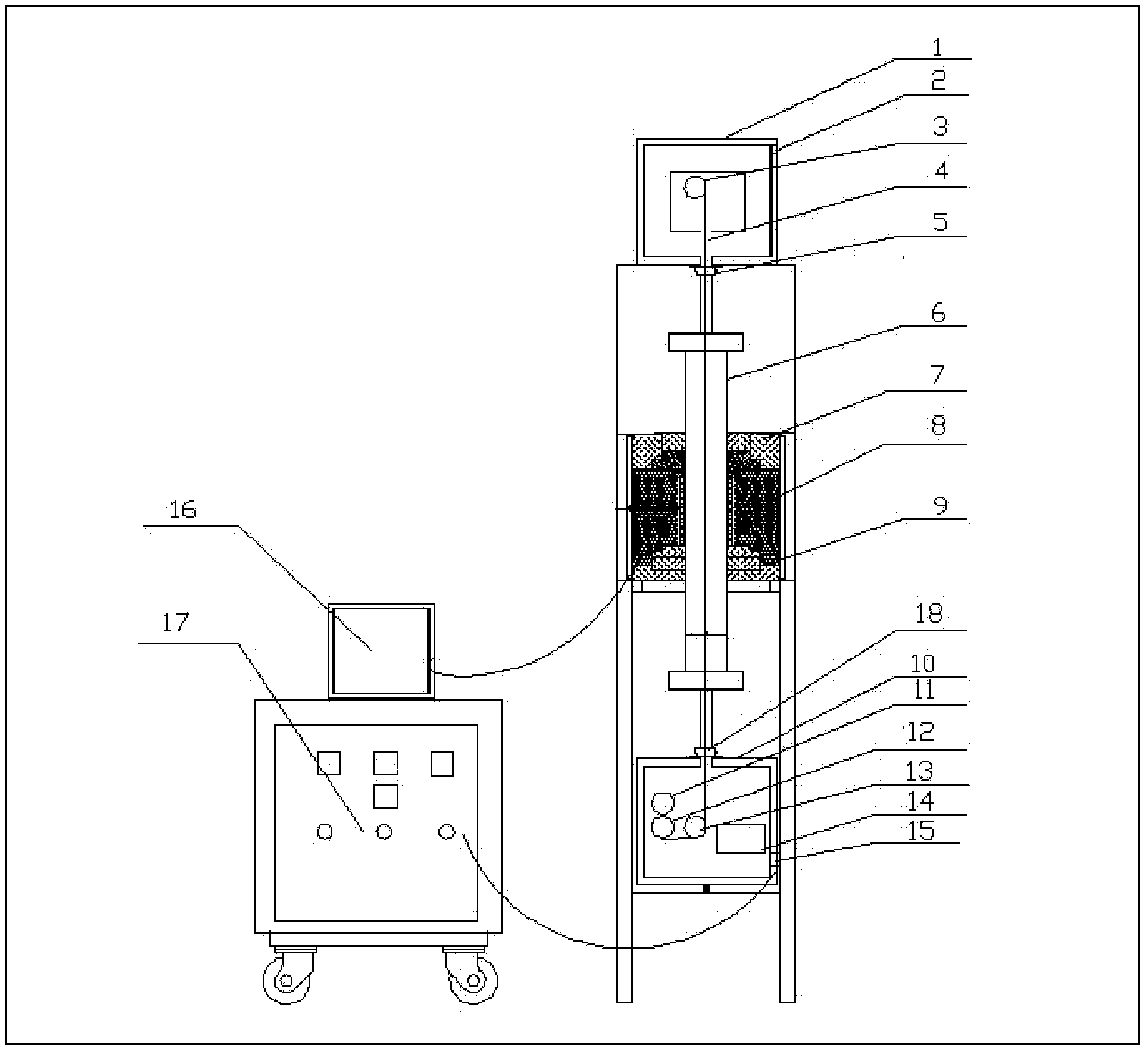

[0018] A kind of vertical annealing furnace, its structure is as figure 1 As shown, it includes retractable belt system, annealing furnace body, thermal system, temperature control system and industrial computer system. The take-up and unwinding system includes a tape release box 1, a tape take-up box 10, a tape release wheel 3, a take-up wheel 12, a paper roll 11, and a guide wheel 13; the thermal system includes insulation materials for protecting the annealing furnace body, and heating control elements 8; the temperature control system includes a temperature control element 9; the industrial computer system includes an industrial computer 16. The belt release wheel is placed in the belt release box, and the belt release box is provided with an air inlet 2. The belt release box is connected and communicated with one end of the annealing furnace body 6 through the entrance sealing device 5, and the belt release wheel is located between the entrance seal device and the anneali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com