Blast rotary-wheel dehumidification device for blast furnace

A technology of dehumidification with a rotary wheel and blast furnace blast, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as high operating costs, larger floor space, and increased investment costs, so as to save operating costs and reduce refining costs. Iron-to-coke ratio and the effect of saving reheat energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

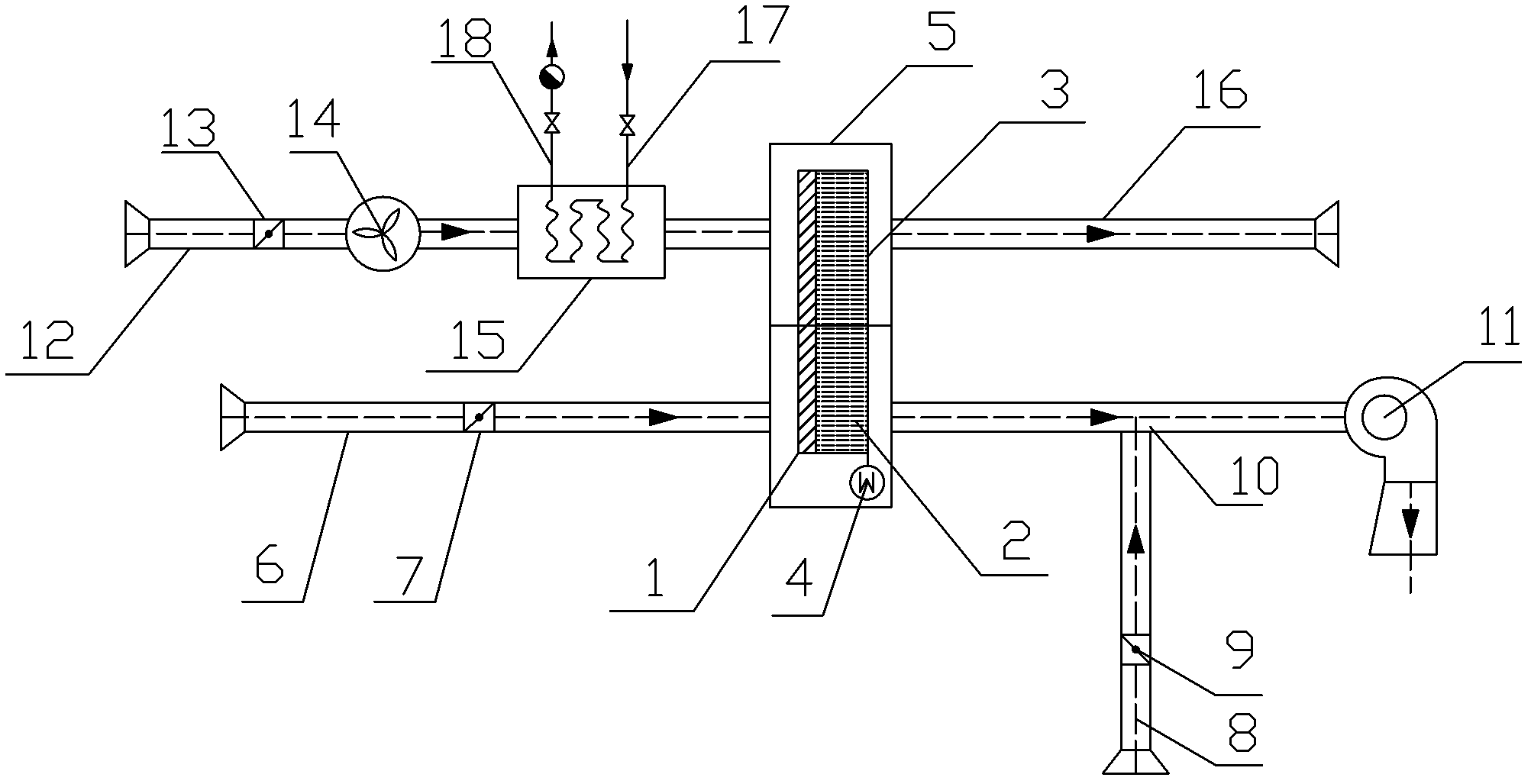

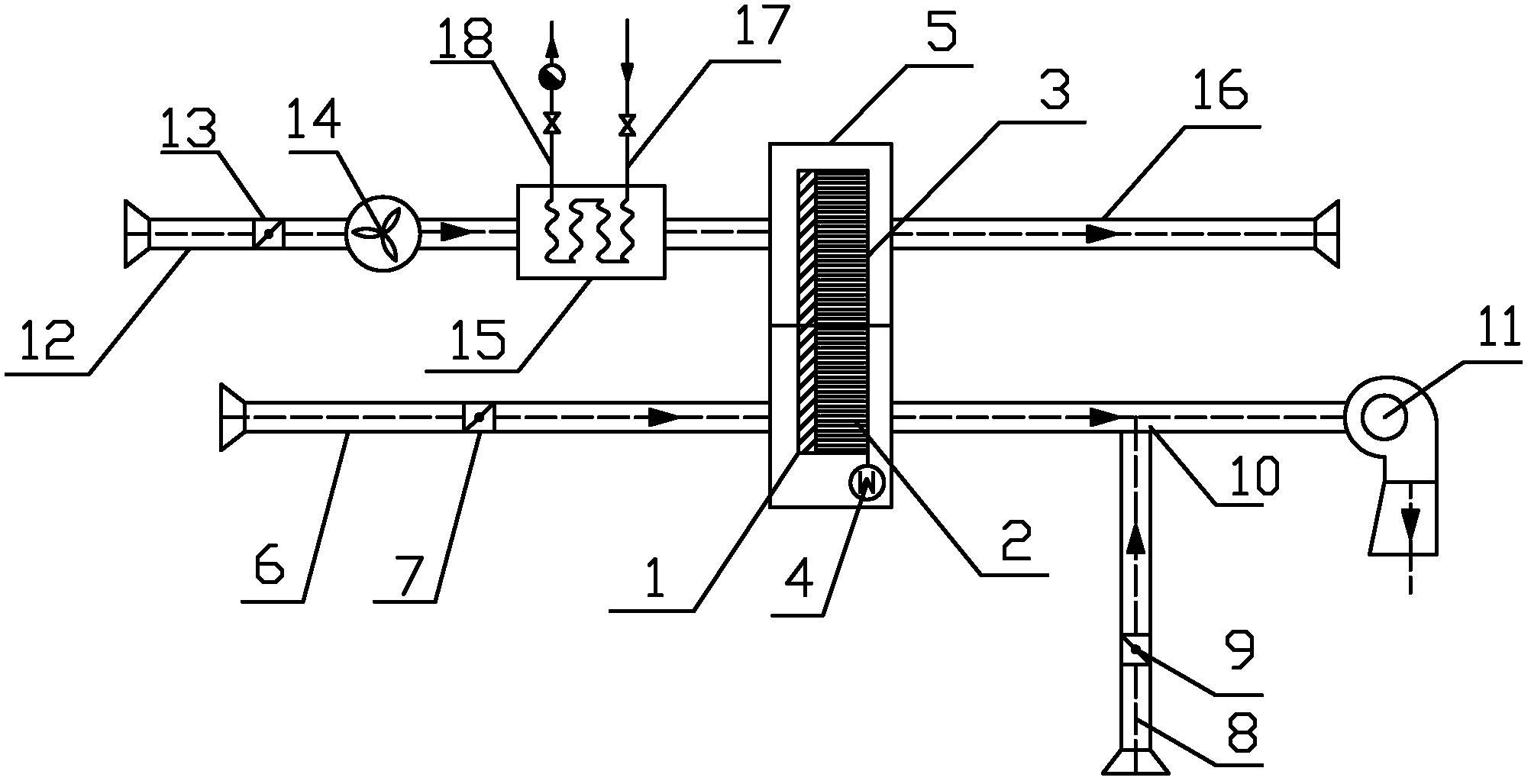

[0028] The following is attached figure 1 The examples and examples further illustrate the present invention, but do not limit the present invention.

[0029] The device of the present invention mainly includes the dehumidification link of the blast runner and the regeneration link of the runner, as well as the bypass link and the heat source steam link. In the wheel dehumidification process, one side of the wheel dehumidifier shell 5 is connected to the inlet air pipe 6, and the inlet air pipe 6 is equipped with an inlet air valve 7, and the wheel dehumidifier shell 5 is equipped with a filter 1, a dehumidification wheel 2 and a rotary The wheel motor 4, the other side of the wheel dehumidifier housing 5 is connected to the outlet air pipe 10, and the outlet air pipe 10 is connected to the blower 11; in the wheel regeneration link, one side of the wheel dehumidifier housing 5 is connected to the regeneration air inlet air pipe 12 Connected, the regeneration air inlet duct 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com