Engineering bacterium for producing alkaline pectinase and application thereof

A pectinase and alkaline technology, applied in the field of engineering bacteria for alkaline pectinase production, can solve the problems of high energy consumption, long fermentation period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

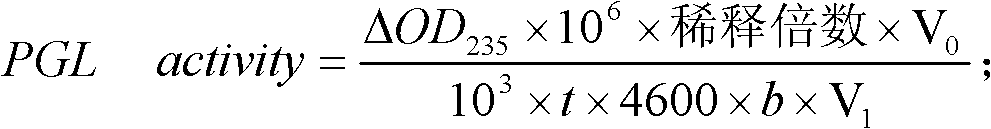

Method used

Image

Examples

Embodiment 1

[0025] Example 1. Acquisition and preservation of engineered bacteria

[0026] 1. The acquisition of engineering bacteria

[0027] 1. Extract the whole genome DNA of soil.

[0028] 2. Design degenerate primers based on the sequence of alkaline pectinase-related genes.

[0029] 3. Using whole genome DNA as a template, PCR amplification is performed with the degenerate primers designed in step 2 to obtain PCR amplification products.

[0030] 4. Sequencing the PCR amplified product of step 3 and discovering a new gene.

[0031] 5. Insert the new gene into the vector pET28b between the NcoI and XhoI restriction sites to obtain a recombinant plasmid.

[0032] 6. Transform the recombinant plasmid into Escherichia coli BL21(DE3) to obtain a recombinant strain (engineered strain), named BL21(DE3)PGL04.

[0033] 2. Preservation of engineered bacteria

[0034] BL21(DE3)PGL04 belongs to Escherichia coli. BL21(DE3)PGL04 has been deposited in the General Microbiology Center of the China Microbial Cultu...

Embodiment 2

[0035] Example 2: Production of alkaline pectinase using engineered bacteria

[0036] 1. Preparation of culture medium

[0037] Seed culture medium (pH7.0): Take 10g tryptone, 5g yeast extract and 5g sodium chloride, dissolve in water and dilute to 1L; sterilize at 121°C for 30min.

[0038] Fermentation medium (pH7.0): Take 10g tryptone, 15g yeast extract, 5g sodium chloride, 10g glycerol, 10mM potassium dihydrogen phosphate and 65mM dipotassium hydrogen phosphate, dissolve in water and dilute to 1L; kill at 121℃ Bacteria 30min.

[0039] 2. Application of engineering bacteria to produce alkaline pectinase

[0040] 1. Inoculate Escherichia coli BL21(DE3)PGL04 to the seed culture medium, and shake culture (100r / min) to OD at 35℃ 600nm = 3, which is the seed liquid.

[0041] 2. Inoculate the seed solution of step 1 into 40mL fermentation medium (using 250mL shake flask) to obtain OD 600nm The initial fermentation system with =0.1; the fermentation process is as follows (43 hours in total...

Embodiment 3

[0058] Example 3: Application of engineered bacteria to produce alkaline pectinase

[0059] 1. Preparation of culture medium

[0060] Seed culture medium (pH 7.2): Take 15g tryptone, 8g yeast extract and 10g sodium chloride, dissolve in water and dilute to 1L; sterilize at 121°C for 30min.

[0061] Fermentation medium (pH7.2): Take 15g tryptone, 23g yeast extract, 10g sodium chloride, 15g glycerol, 17mM potassium dihydrogen phosphate and 75mM dipotassium hydrogen phosphate, dissolve in water and dilute to 1L; kill at 121℃ Bacteria 30min.

[0062] 2. Application of engineering bacteria to produce alkaline pectinase

[0063] 1. Inoculate Escherichia coli BL21 (DE3) PGL04 to the seed medium, and shake culture (200r / min) at 37℃ to OD 600nm = 6, which is the seed liquid.

[0064] 2. Inoculate the seed solution of step 1 into 20mL fermentation medium (using 250mL shake flask) to obtain OD 600nm Fermentation initial system = 0.2; the fermentation process is as follows (53 hours in total): fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com