Novel low-temperature phase-change thermal storage material and preparation method thereof

A technology of low-temperature phase change and heat storage materials, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as inappropriate phase change temperature of phase change heat storage materials, vacancy of phase change materials, and unstable performance. Achieve the effects of easy packaging, stable exothermic process, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

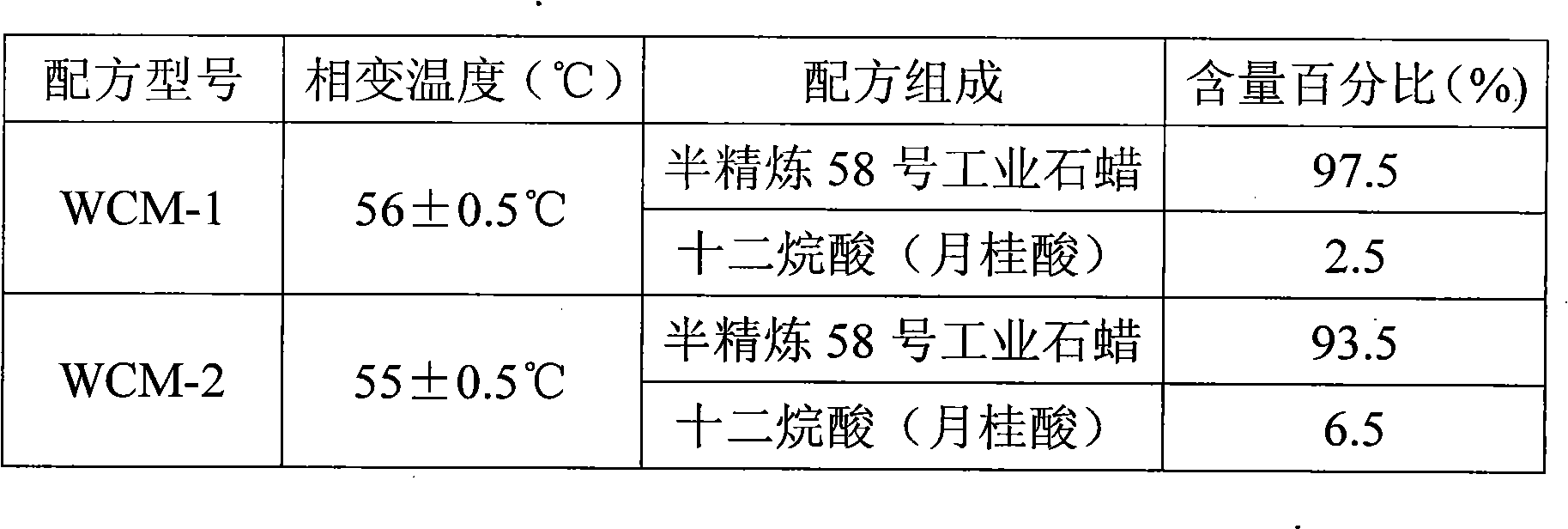

[0014] In order to better understand the present invention, further description is given below in conjunction with the preparation steps of the formula type phase change heat storage material of the embodiment shown in Table 1:

[0015]

[0016] Table 1

[0017] The preparation method of the above formula is as follows:

[0018] According to the ingredients, first put the main material semi-refined No. 58 industrial paraffin in the equipment of 56℃~68℃, heat and melt, add the additive dodecanoic acid (lauric acid) after complete melting, and stir evenly. During the stirring process The mixture is then heated up again to make it fully mixed into a white transparent liquid, and finally poured into a container for packaging.

[0019] The following matters should be paid attention to in the production process:

[0020] (1) The above chemical components need to be sealed and stored when they are in stock, especially dodecanoic acid (lauric acid) exposed to the air at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com