High-hydroscopicity polyvinyl chloride (PVC) material and preparation method

A high water absorption, granular material technology, applied in the field of plastic products, can solve problems such as poor water absorption, and achieve the effect of good mechanical properties and good water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

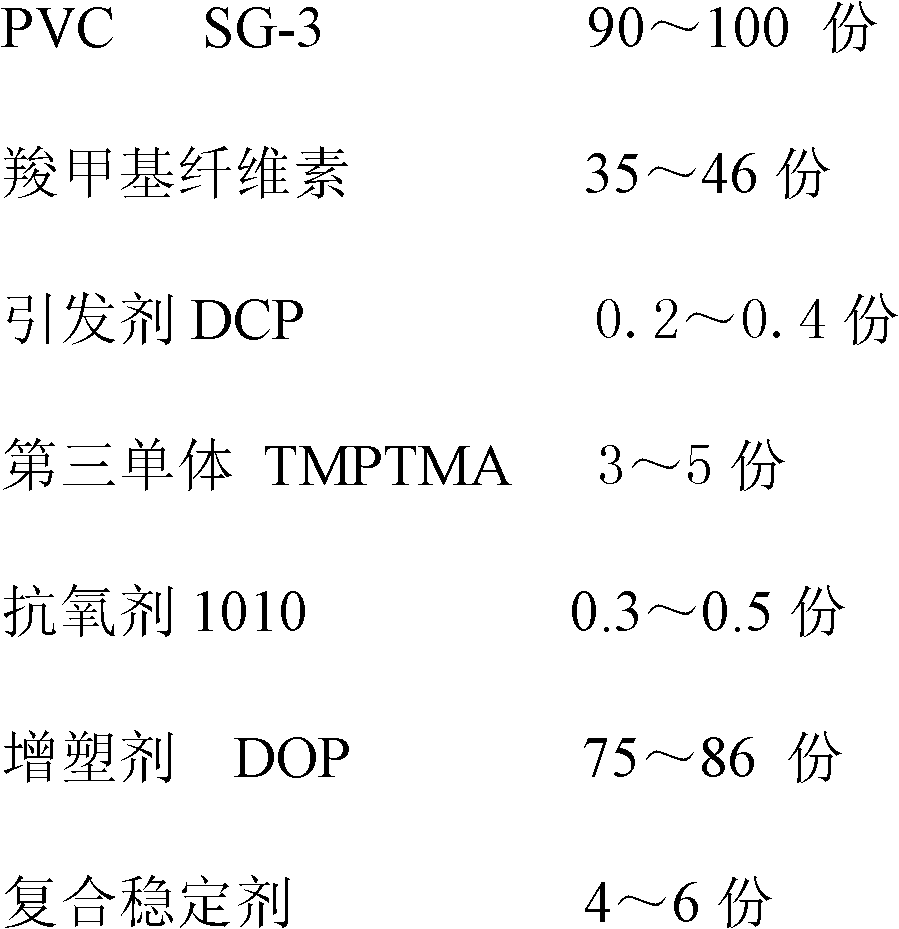

Method used

Image

Examples

Embodiment 1

[0024] First, stir PVC SG-3 90Kg, plasticizer DOP 75Kg, composite stabilizer 4Kg, antioxidant 1010 0.3Kg, third monomer TMPTMA 3Kg at a speed of 900 rpm until the temperature of the mixture is 50-56 ℃;

[0025] Then, add initiator DCP 0.2Kg, carboxymethyl cellulose 35Kg and stir at a speed of 900 rpm for 5-6 minutes, and stop stirring when the temperature of the mixture reaches 90-92°C;

[0026] Finally, extrude and granulate the above mixture in a twin-screw extruder, and the temperature of each section of the twin-screw extruder is 1#130°C, 2#140°C, 3#160°C, 4#165°C, 5#160°C , 6# 160°C, machine head 150°C, the PVC granular material with high water absorption performance is obtained.

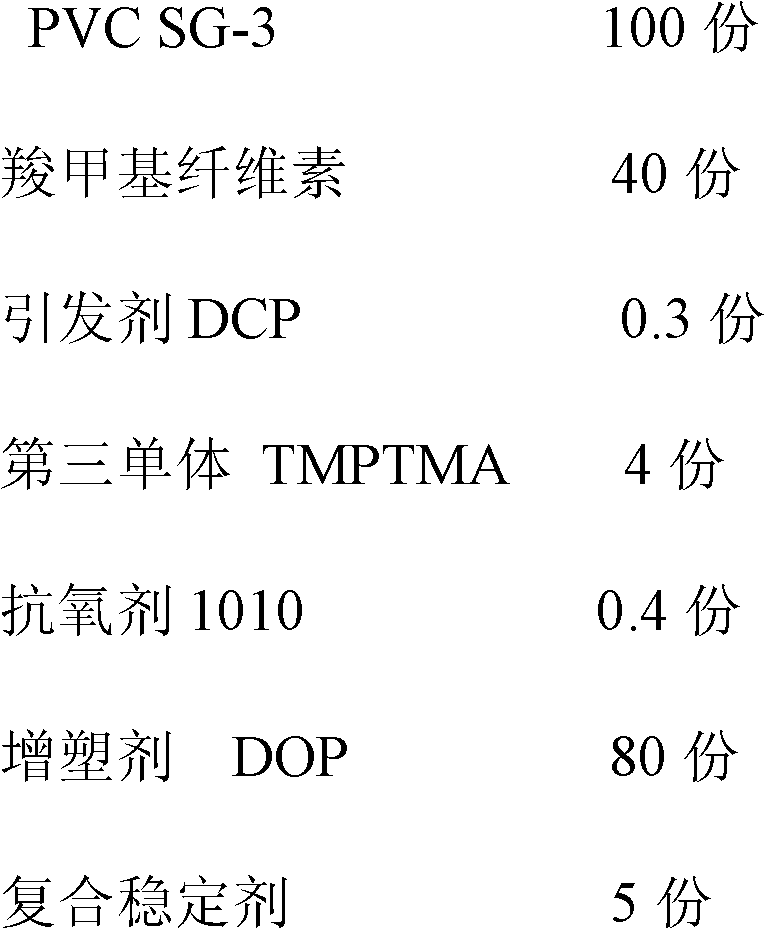

Embodiment 2

[0028] Same as the preparation steps in Example 1, with the following differences:

[0029] PVC SG-3 100Kg, plasticizer DOP 80Kg, aluminum salt composite stabilizer 5Kg, antioxidant 10100.4Kg, third monomer TMPTMA 4Kg, initiator DCP 0.3Kg, carboxymethyl cellulose 40Kg.

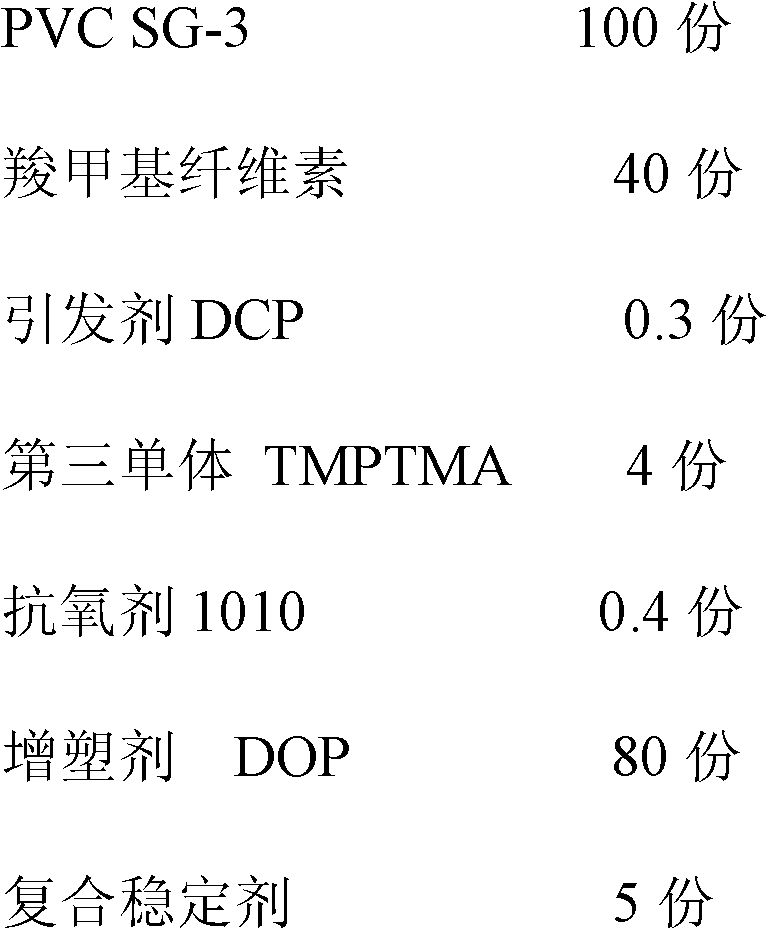

Embodiment 3

[0031] Same as the preparation steps in Example 1, with the following differences:

[0032] PVC SG-3 100Kg, plasticizer DOP 86Kg, aluminum salt composite stabilizer 6Kg, antioxidant 10100.5Kg, third monomer TMPTMA 5Kg, initiator DCP 0.4Kg, carboxymethyl cellulose 46Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com