Cement modifier

A conditioner and cement technology, applied in the field of cement conditioners, can solve the problems of high cost and incomplete functions of cement conditioners, and achieve the effects of reducing shrinkage cracks due to temperature differences, improving frost resistance, and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Based on 100kg product, it contains 1kg of cellulose ether, 6kg of fiber, 12kg of cross-linked polyacrylate, 8kg of montmorillonite, 12kg of ethoxylated sodium alkyl sulfide, and the rest is kaolin. The mortar formula is as follows: by mass: water: cement: sand: cement regulator = 0.48:1:3:0.01. Using the regulator of this formula, the delamination degree of the mortar can be reduced to less than 18mm, and the water retention rate is 80%, which improves the performance of the mortar. Frost resistance, reduce the shrinkage rate of mortar, 30d compressive strength 13MPa, 30d bond strength 0.4MPa, frost resistance: 30d mass loss 3%, strength loss 18%, 30d shrinkage rate 0.4%; setting time 5 hours; and The use of the preferred formula of the present invention greatly improves the performance of the mortar.

Embodiment 2

[0023] Based on 100kg product, it contains 1.2kg of cellulose ether, 8.8kg of fiber, 10kg of cross-linked polyacrylate, 10kg of montmorillonite, 10kg of ethoxylated sodium alkyl sulfide, 10kg of starch grafted acrylonitrile, and dibutyl tin dilaurate The remaining 10kg is kaolin. The mortar formula is as follows: by mass: water: cement: sand: cement conditioner = 0.45:1:3:0.01. Using the regulator of this formula, the delamination degree of the mortar can be reduced to 15mm, the water retention rate is above 85%, the frost resistance of the mortar is improved, and the shrinkage rate of the mortar is reduced. The 30d compressive strength is 15MPa, the 30d bond strength is 0.5MPa, and the freeze resistance Properties: 30d mass loss 2%, strength loss 15%, 30d shrinkage rate 0.3%; setting time 4 hours; and the use of the preferred formula of the present invention greatly improves the performance of the mortar.

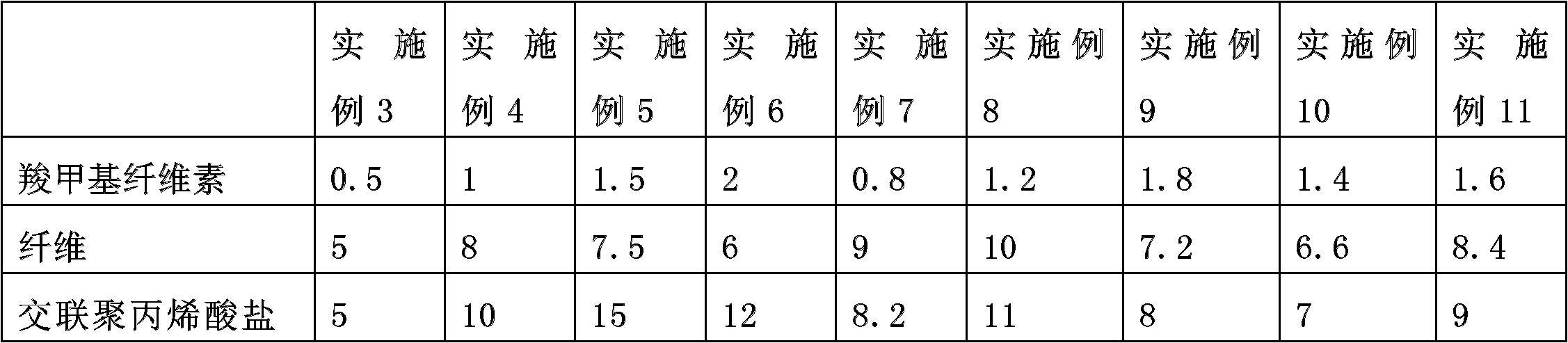

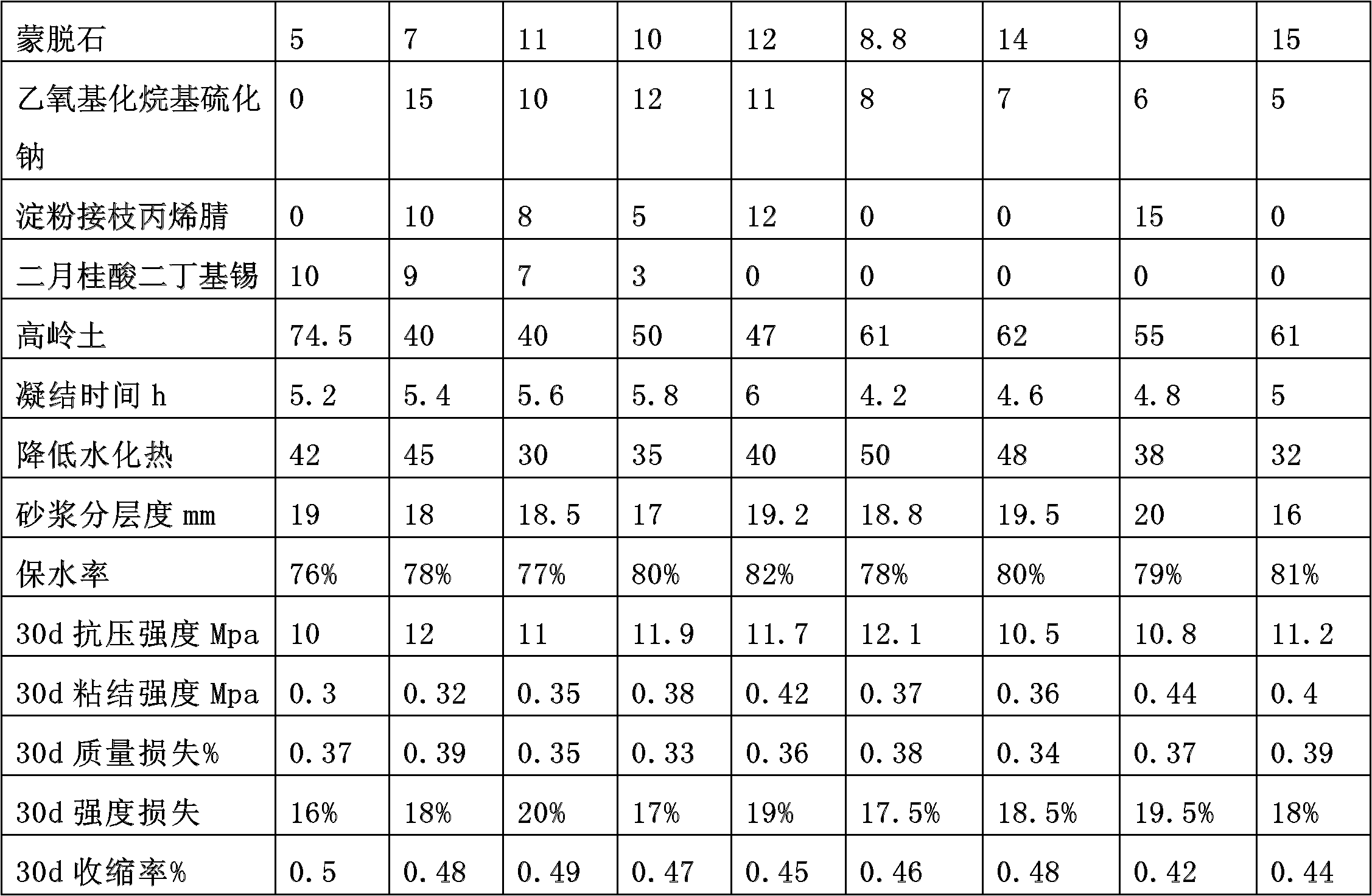

Embodiment 3-11

[0025] The mortar formula is as follows: by mass: water: cement: sand: cement conditioner = 0.5:1:3:0.01.

[0026] The formula of each example is as follows, and the measured data is as follows.

[0027]

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com