Heat insulation energy-saving new material WO3 nanometer powder and preparation method thereof

A technology of nano-powder and energy-saving material, which is applied in the preparation of heat-insulating and energy-saving WO3 nano-powder, and the field of heat-insulating and energy-saving WO3 nano-powder, can solve the problems of poor reflection and absorption ability, unsatisfactory transparent heat insulation performance of heat insulation film, etc. , to achieve the effect of good transparency, important social and economic value, and high thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

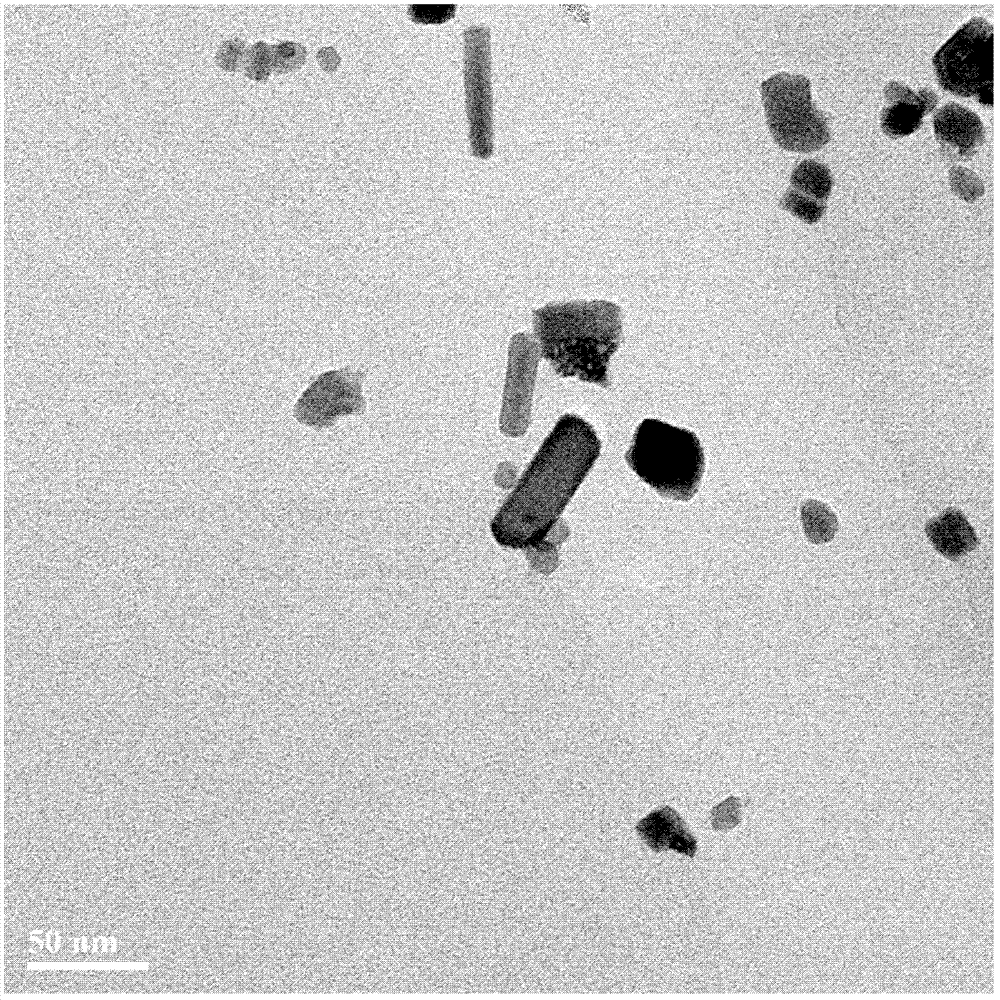

Image

Examples

Embodiment 1

[0023] Weigh 400gWO respectively 3 Powder, 200g tin hydroxide Sn(OH) 2 Powder, 20gSb(OH) 3 Powder, 200g Cs 2 O powder, 400g mixed solution and 400g ammonia water.

[0024] Add the above substances into the container one by one and stir with a shearing machine, adjust the speed to 1200 rpm, after 10 minutes, adjust the pH value of the mixed colloid in the container with hydrochloric acid, control the pH value to 5-5.5, and then stir for 20 minutes , and then take out the mixed colloid in the container and pour it into Al 2 o 3 Put the crucible into the drying box for drying, adjust the temperature to 90 degrees and dry for 6 hours, then raise the temperature to 180 degrees for 6 hours, and then put it into the muffle furnace for calcination after cooling, the temperature is controlled at 600 degrees, immediately Connect the nitrogen gas in the muffle furnace, adjust the nitrogen flow rate to 20 cubic meters per minute, control the heating time to 2 hours, and then cool nat...

Embodiment 2

[0028] Weigh 800gWO respectively 3 Powder, 300g tin hydroxide Sn(OH) 2 Powder, 80gSb(OH) 3 Powder, 400g Cs 2 O powder, 500g mixed solution and 550g ammonia water.

[0029] Add the above substances into the container one by one and stir with a shearing machine, adjust the speed to 1300 rpm, after 10 minutes, adjust the pH value of the mixed colloid in the container with hydrochloric acid, control the pH value to 5-5.5, and then stir for 40 minutes , and then take out the mixed colloid in the container and pour it into Al 2 o 3 Put the crucible into the drying box for drying, adjust the temperature to 85 degrees for 5 hours, then raise the temperature to 160 degrees for 8 hours, and then put it into the muffle furnace for calcination after cooling, the temperature is controlled at 630 degrees, and the Connect the nitrogen gas in the muffle furnace, adjust the nitrogen flow rate to 15 cubic meters per minute, control the heating time to 3 hours, and then cool naturally. You...

Embodiment 3

[0033] Weigh 600gWO respectively 3 Powder, 250g tin hydroxide Sn(OH) 2 Powder, 50gSb(OH) 3 Powder, 300g Cs 2 O powder, 450g mixed solution and 475g ammonia water.

[0034] Add the above substances into the container one by one and stir with a shearing machine, adjust the speed to 1400 rpm, after 10 minutes, adjust the pH value of the mixed colloid in the container with hydrochloric acid, control the pH value to 5-5.5, and then stir for 60 minutes , and then take out the mixed colloid in the container and pour it into Al 2 o 3Put the crucible into the drying box for drying, adjust the temperature to 95 degrees and dry for 6 hours, then increase the temperature to 200 degrees for 4 hours, and then put it into the muffle furnace for calcination after cooling, the temperature is controlled at 650 degrees, and the Connect the nitrogen gas in the muffle furnace, adjust the nitrogen flow rate to 25 cubic meters per minute, control the heating time to 3 hours, then cool naturally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com