Off-road type forklift with hydrostatic four-wheel drive and articulated frame

A four-wheel drive, hydrostatic technology, applied to vehicle components, fluid steering mechanisms, lifting devices, etc., can solve problems such as uneven forklifts, limited forklift use range, muddy and soft roads, and achieve small turning radius and extended use The effect of strong surface and off-road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

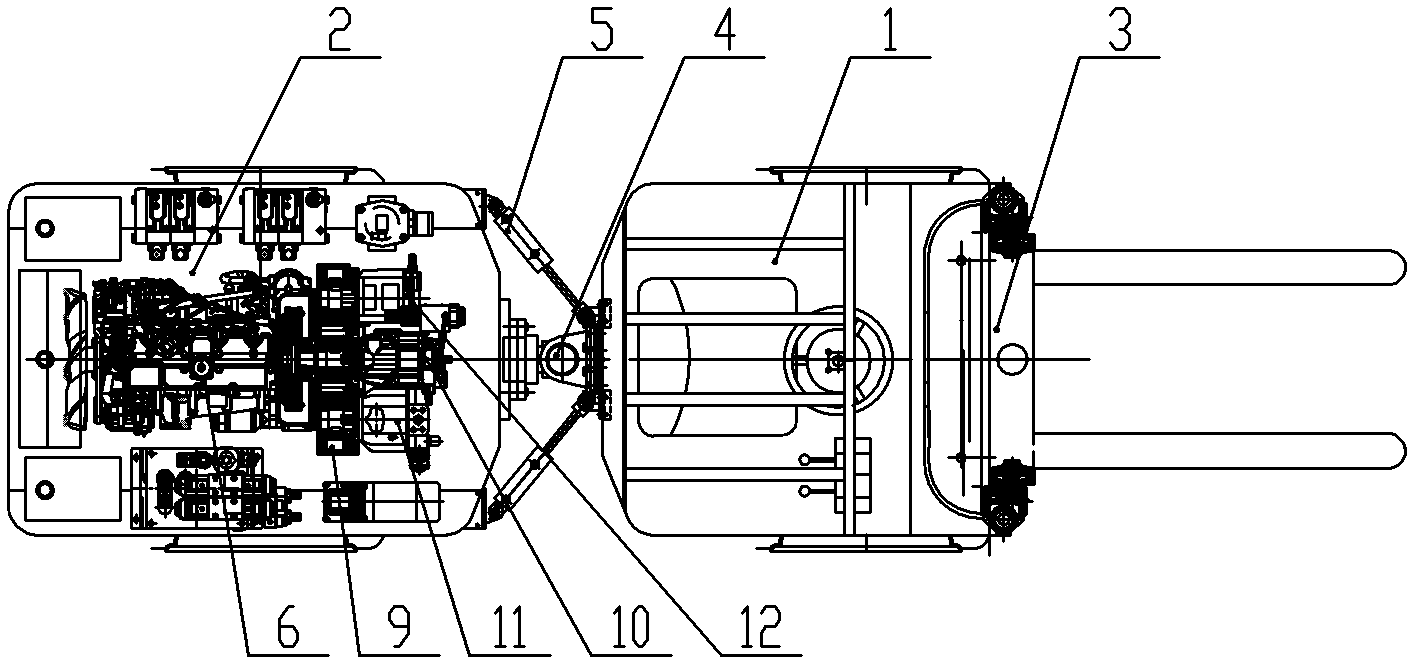

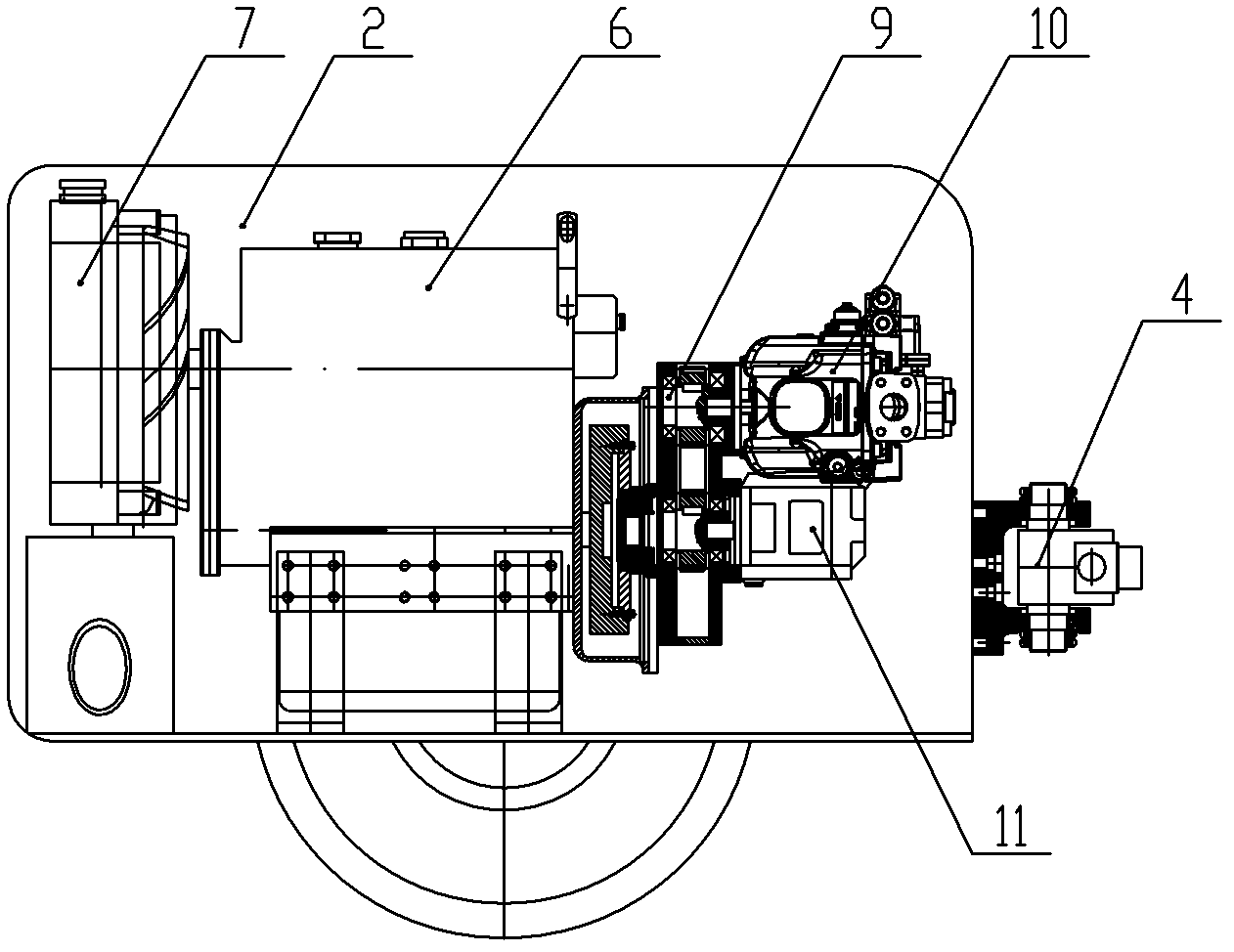

[0023] Figure 1~Figure 18 Including the front body 1, the rear body 2, the lifting mechanism 3, the hinge mechanism 4, the steering cylinder 5, the engine 6, the water tank 7, the fuel tank 8, the transfer case 9, the variable pump 10, and the first quantitative pump 11 , the second quantitative pump 12, hydraulic motor 13, wheel 14, box 19, input shaft 20, input gear 21, intermediate gear 22, bearing 23, intermediate gear shaft 24, output shaft 25, output gear 26, bolt 27, bolt 28. Cockpit 29, overhead guard 30, hydraulic steering gear 31, manual multi-way reversing valve 32, outer mast 33, inner mast 34, lifting cylinder 35, tilting cylinder 36, rotating arm 37, lifting chain 38 , carriage 39, cargo fork 40, upper bearing seat 41, lower bearing seat 42, rotating shaft mount 43, T-shaped shaft 44, bearing 45, front and rear bearing 46, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com