Off-road reach stacker for freight container

A technology of reach stacker and container, which is applied in the direction of cranes, etc. It can solve the problems of no steering function, high vehicle height, and no ability to operate in field environments, so as to achieve the effect of convenient transportation and lower vehicle height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

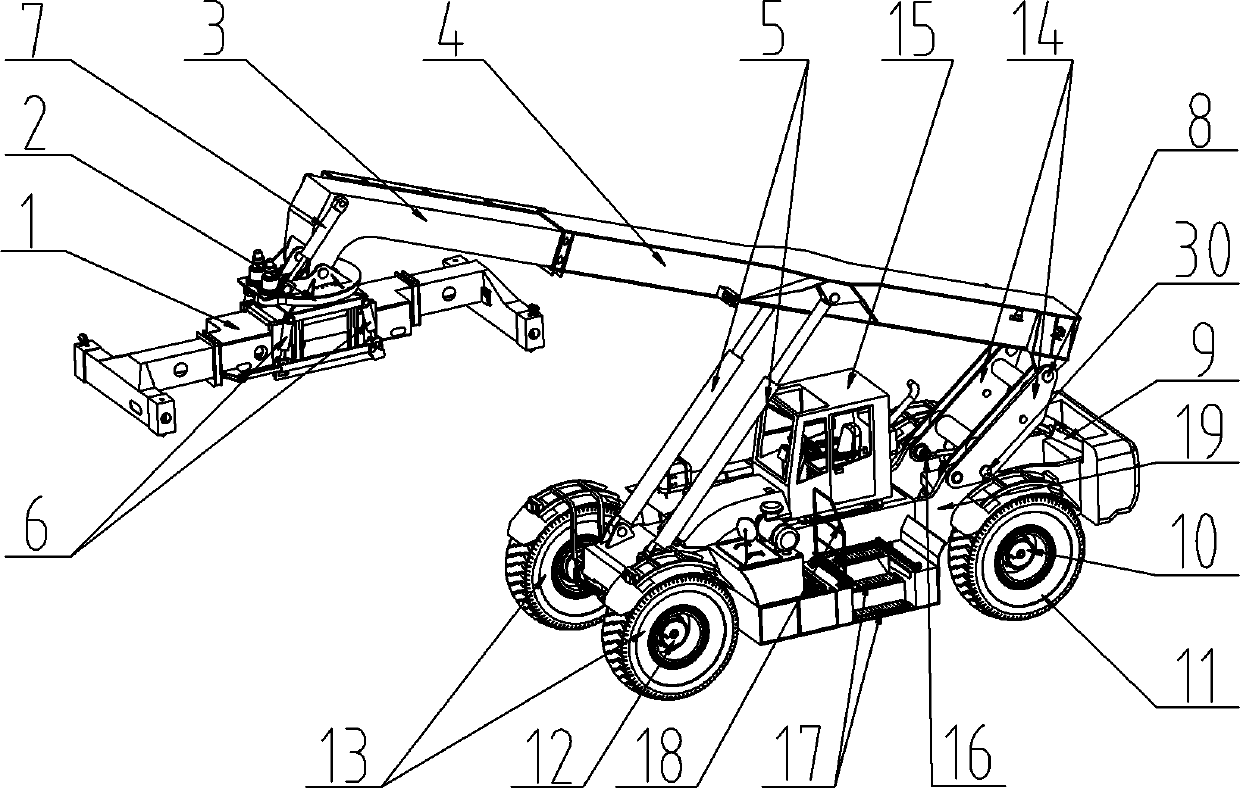

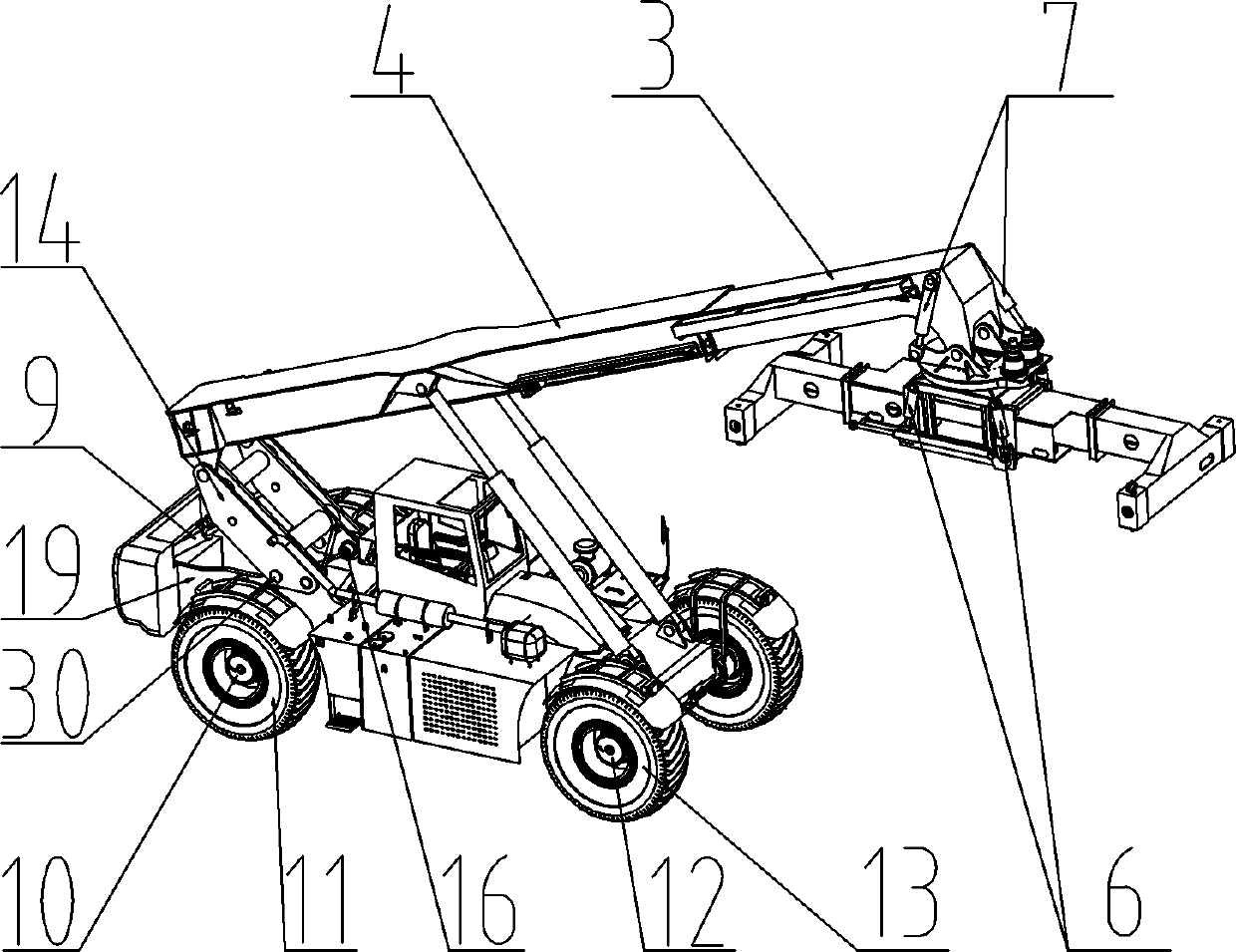

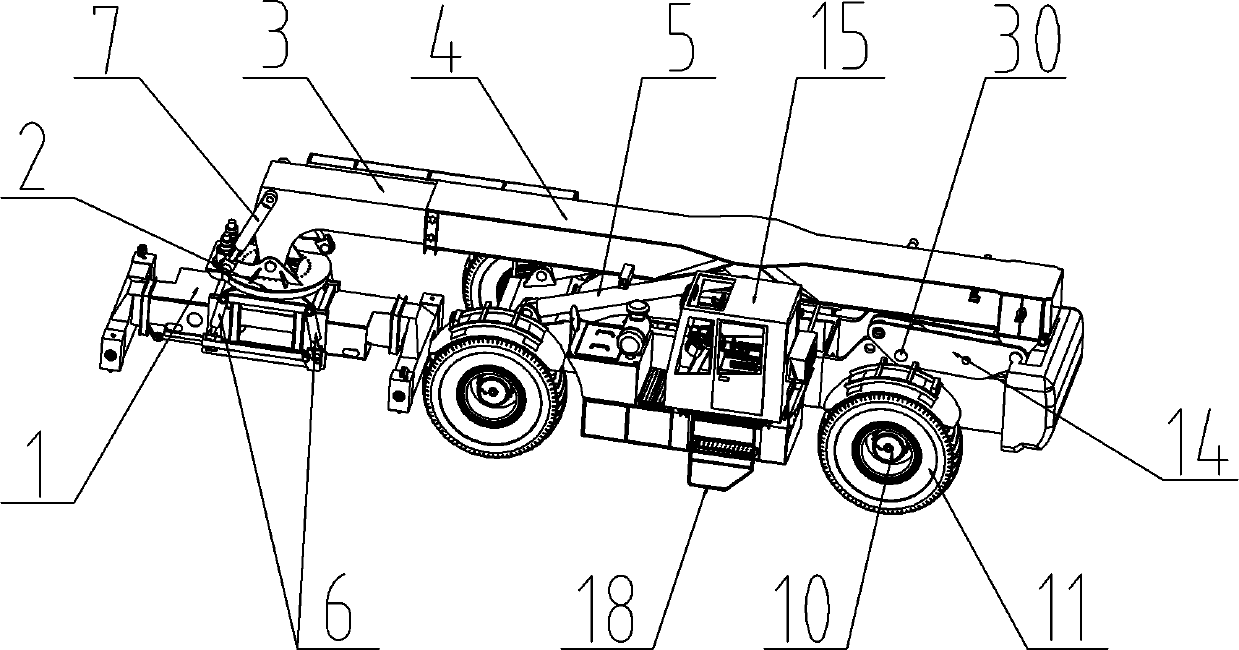

[0017] refer to figure 1 , 2 , shown in 3, the present invention comprises an integral vehicle frame chassis 19, front steering drive axle 12 is set on the vehicle frame 19, rear steering drive axle 10, front steering drive axle is equipped with front-wheel 13, rear steering drive axle is equipped with front-wheel 11. A closed floating cab 15 is set in the middle of the vehicle frame 19, a support mechanism 14 and a support cylinder 9 are provided at the rear end of the vehicle frame 19, and a limit oil cylinder 16 is provided in the support mechanism 14 to ensure that the support mechanism 14 in the working state of the whole vehicle can be reliably and The frame 19 is connected to meet the safety requirements; the limit oil cylinder 16 is pulled out, and under the action of the support cylinder 9, the support mechanism 14 can rotate around the frame 19 through the rotating shaft 30 to meet the transportation requirements of reducing the height of the vehicle; the support mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com