Box packing machine with upward opening cover

A technology of capping and box delivery, which is applied in packaging, packaging bottles, transportation and packaging, etc., and can solve problems such as low work efficiency, complex structure, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

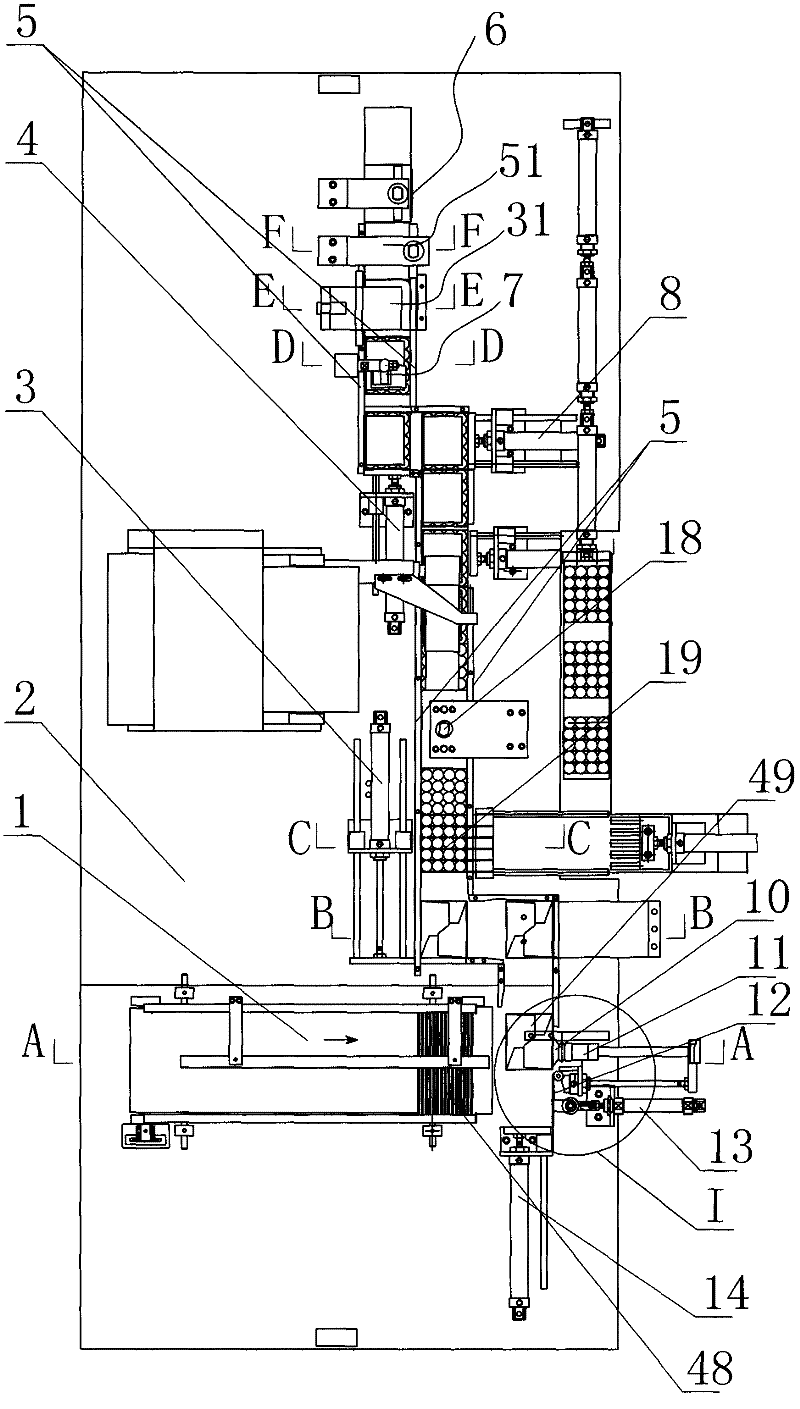

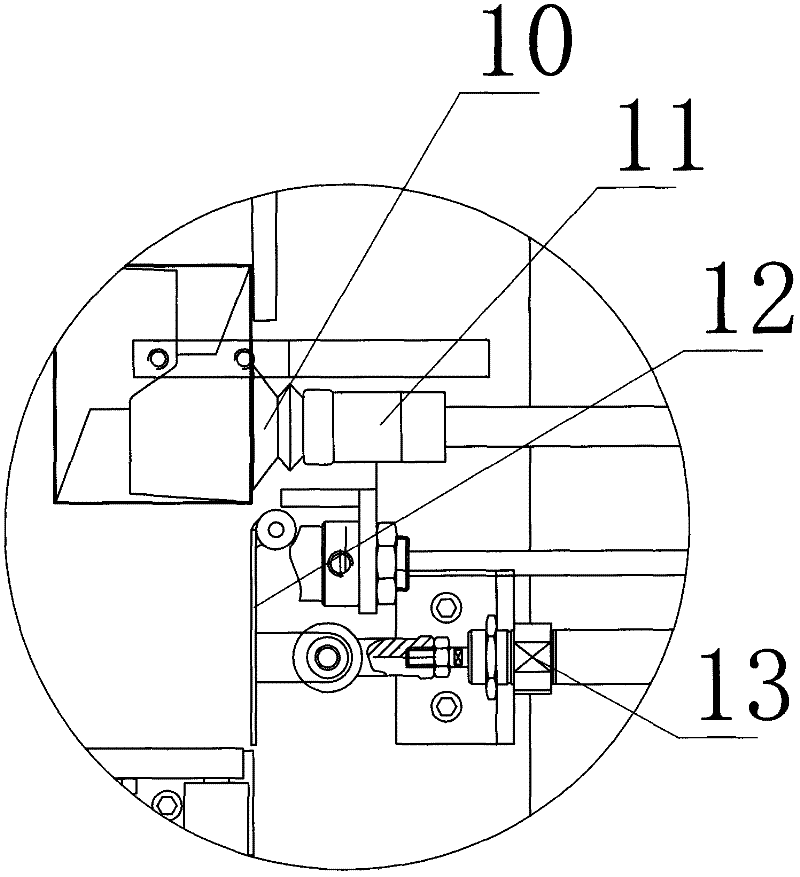

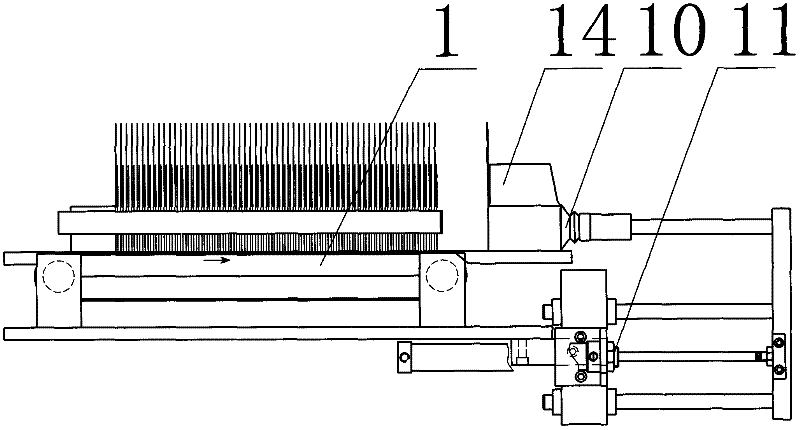

[0030] Embodiment one, with reference to Figure 1 to Figure 9, this top-opening cartoning machine includes a suction box forming mechanism, a box-feeding mechanism, a feeding mechanism and a tongue-inserting mechanism 6, and the box-feeding mechanism includes an operating platform 2, a baffle plate 5, and cylinders 14, 9, 3, 8 , 4, wherein the baffle plate 5 and the operating platform 2 constitute a flat-push box delivery track, wherein the cylinders 14, 9, 3, 8, and 4 are all arranged at right-angle turns of the box delivery track, and the suction box forming mechanism includes Suction cup 10, suction cup cylinder 11, push plate 12 and forming cylinder 13, its suction cup 10 is installed on the piston rod of suction cup cylinder 11, push plate 12 is hinged on the body, and is connected with the piston rod of forming cylinder 13, while sending box The baffle plate 5 of track is provided with the through hole (not shown) that sucker 10 passes through; Flat paper box 48, just ...

Embodiment 2

[0031] Embodiment two, refer to Figure 10 The means of the device for creating a gap between the tongue-inserting surface of the box body and the packaged object described in this embodiment are different, and the other structures are the same as the first embodiment. In this embodiment, the device for creating a gap between the tongue-inserting surface of the box body and the packaged object includes a suction nozzle 41 and a suction nozzle cylinder 42 , and the suction nozzle 41 is installed on the piston rod of the suction nozzle cylinder 42 . After the carton 49 is sent to the upper cover inward folding station 51 by the box delivery track, it moves to the next station tongue insertion mechanism 6. Surface 37 sucks, and then, the piston rod of suction nozzle cylinder 42 shrinks, and suction nozzle 41 leaves the package 19 in the carton 49 with box body tongue-inserting surface 37 and produces gap, then the cover box block of tongue-inserting mechanism 6 35 is pushed down...

Embodiment 3

[0032] Embodiment three, refer to Figure 11 ~ Figure 12 The means of the device for creating a gap between the tongue-inserting surface of the box body and the packaged object described in this embodiment are different, and the other structures and processes are also the same as in the first embodiment. In this embodiment, the device for creating a gap between the tongue-inserting surface of the box body and the packaged object includes an inner guide rod 40 , which is installed in the box feeding track and forms an angle with the baffle plate 5 . After the carton 49 was delivered to the loam cake folding station 51 by the box delivery track, the tongue 37 on the upper cover 29 was folded inward and was inserted into the carton 49 by a small part, and moved to the next station. When the tongue-inserting mechanism is at 6 places, due to the effect of the inner guide rod 40, and the inner guide rod 40 forms an included angle with the baffle plate 5, the tongue-inserting 50 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com