Pattern structure of bicycle pneumatic tire suitable for four seasons

A technology of pneumatic tires and pattern structure, applied in the direction of tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problems of loud noise and beating of stud tires, affecting riding comfort, increasing rolling resistance, etc. Achieve the effect of less irregular wear, improved tire grip and drainage performance, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

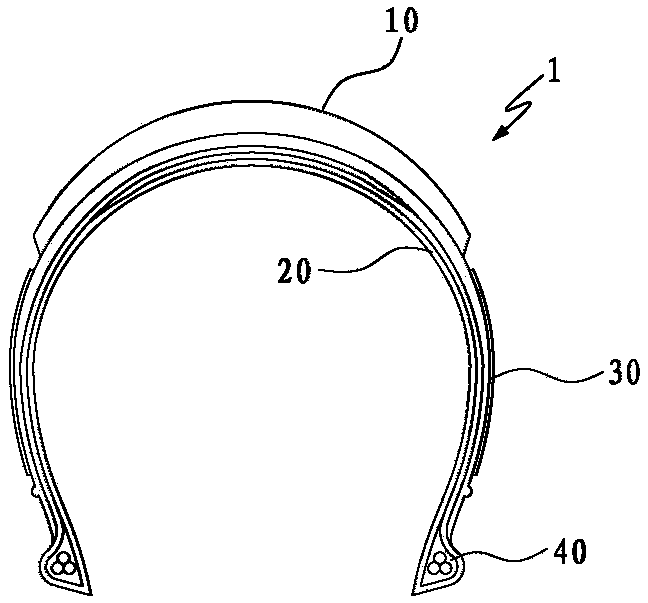

[0038] Such as Figure 1 to Figure 5 As shown, the present invention discloses a tread structure of a four-season bicycle pneumatic tire. exist figure 1 , the vertical direction is set as the tire radial direction, and the lateral direction is set as the tire axial direction; the tire 1 includes a tread portion 10 , a carcass layer 20 , side bead portions 30 and a pair of beads 40 .

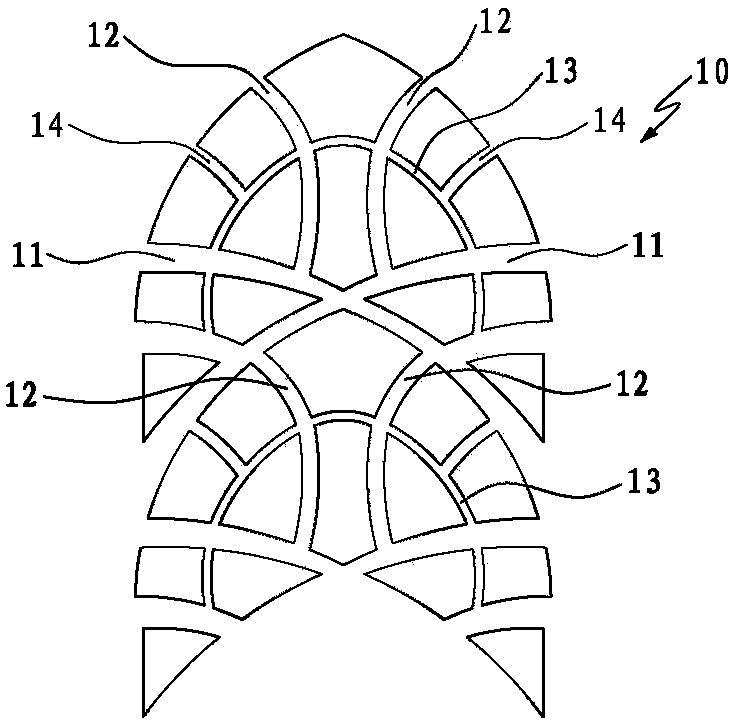

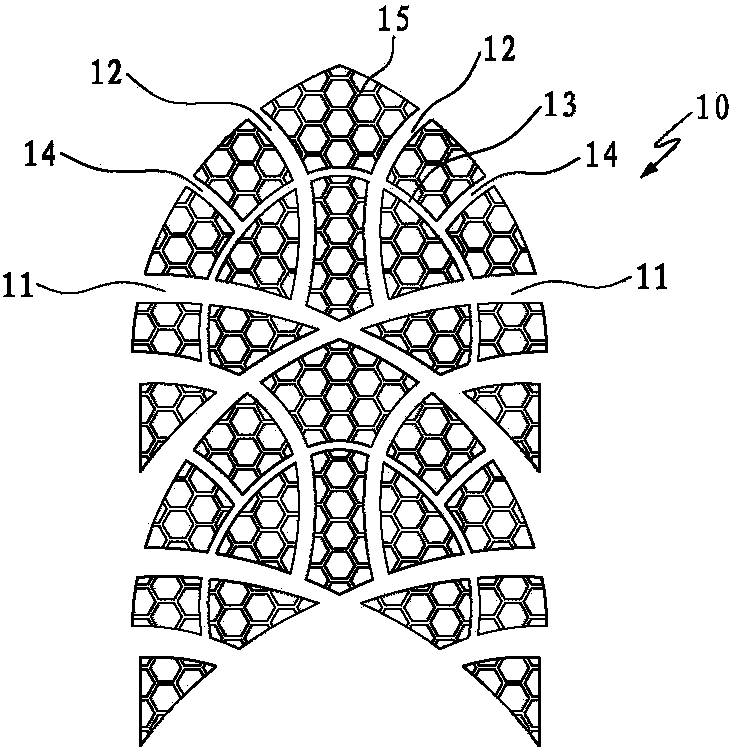

[0039] Such as figure 2 As shown, the tread portion 10 of the tire 1 is formed by a plurality of pattern units arranged continuously, and each pattern unit includes two intersecting pattern main grooves 11, two symmetrically arranged pattern circular arc main grooves 12 and one pattern arc secondary groove 13, Pattern blocks are formed between the pattern grooves; the two pattern main grooves 11 are respectively symmetrical and arc-shaped extending downward from one side of the tread portion 10 to the other side of the tread portion 10; and the two pattern arc main grooves 12 are respectively ...

Embodiment

[0047] Tire specification: 37-622 (28X1*5 / 8X1*3 / 8)

[0048] Vehicle used: install 28-inch city car front and rear wheels

[0049] Road conditions: winter roads, including dry asphalt roads and wet ice and snow roads.

[0050] Evaluation items: rolling resistance, grip performance, handling performance

[0051] Evaluation method: sensory evaluation by test drivers, 10-point method for evaluation, the larger the score, the better the performance.

[0052]

[0053] In summary, the present invention makes the overall tread pattern into a tortoise shell shape through the design of the main grooves 11, 12 and auxiliary grooves 13 on the tread portion 10 of the tire 1, forming an optimized land-to-sea ratio design, thereby improving tire grip and drainage performance. In addition, evenly distributed polygonal grooves 15 are arranged on the pattern blocks of the entire tread portion 10, and the grooves 15 are connected to each other and penetrate to the edges of the pattern bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com