Printer carriage guiding mechanism

A guiding mechanism and printer technology, which is applied in the field of printer equipment, can solve problems such as unsatisfactory printing effects, achieve smooth lateral movement and ensure printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

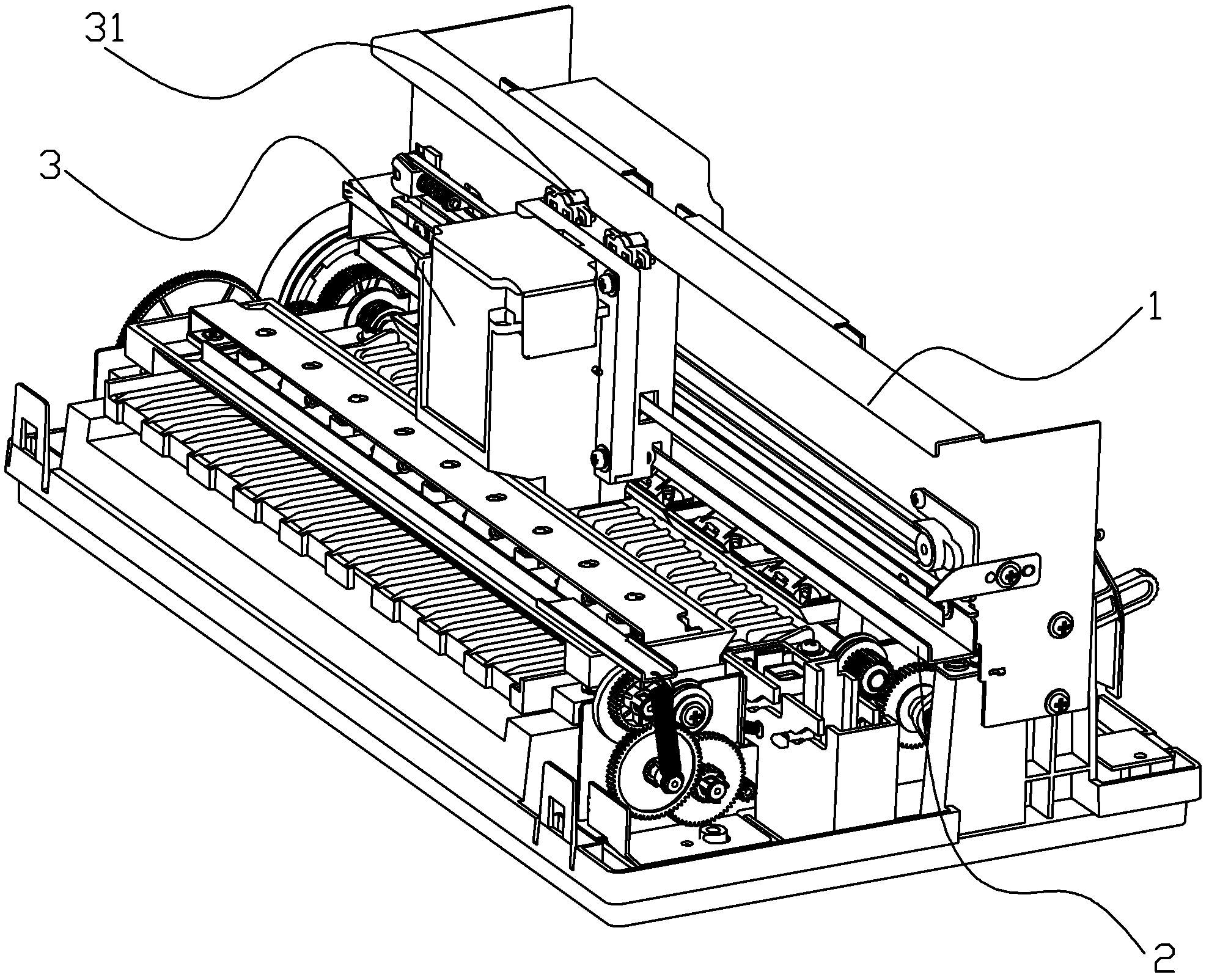

[0014] refer to Figure 1 to Figure 3 , a kind of printer word car guiding mechanism, at first fixedly installed on the printer, the upper and lower horizontal guide rails 1,2 of upper and lower parallel to each other.

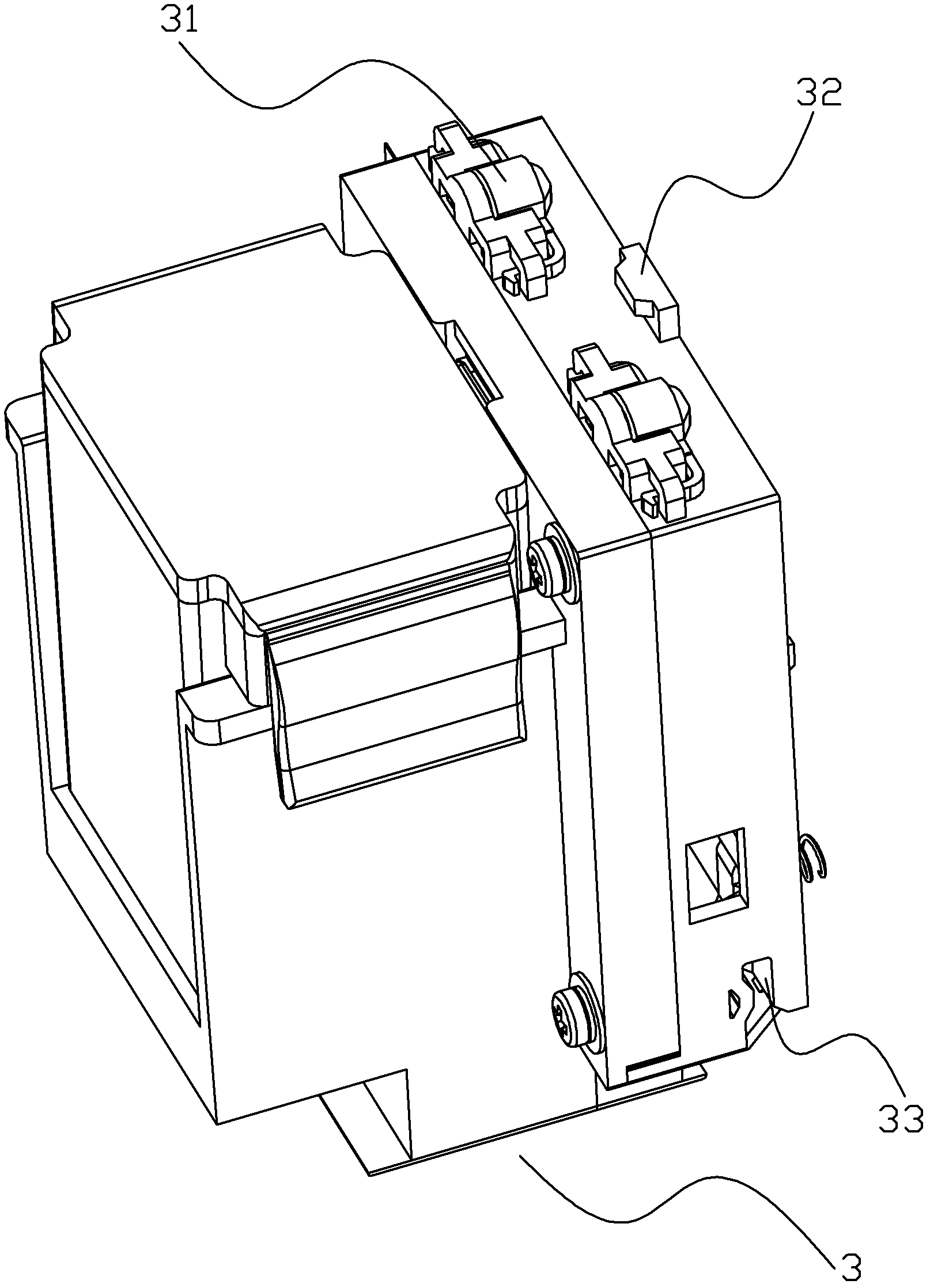

[0015] Further, process the character carriage 3 that can be connected and installed between the upper and lower crossbeam guide rails 1, 2, and then process the guide rail groove 33 used in conjunction with the lower transverse guide rail 2 at the bottom of the character carriage 3.

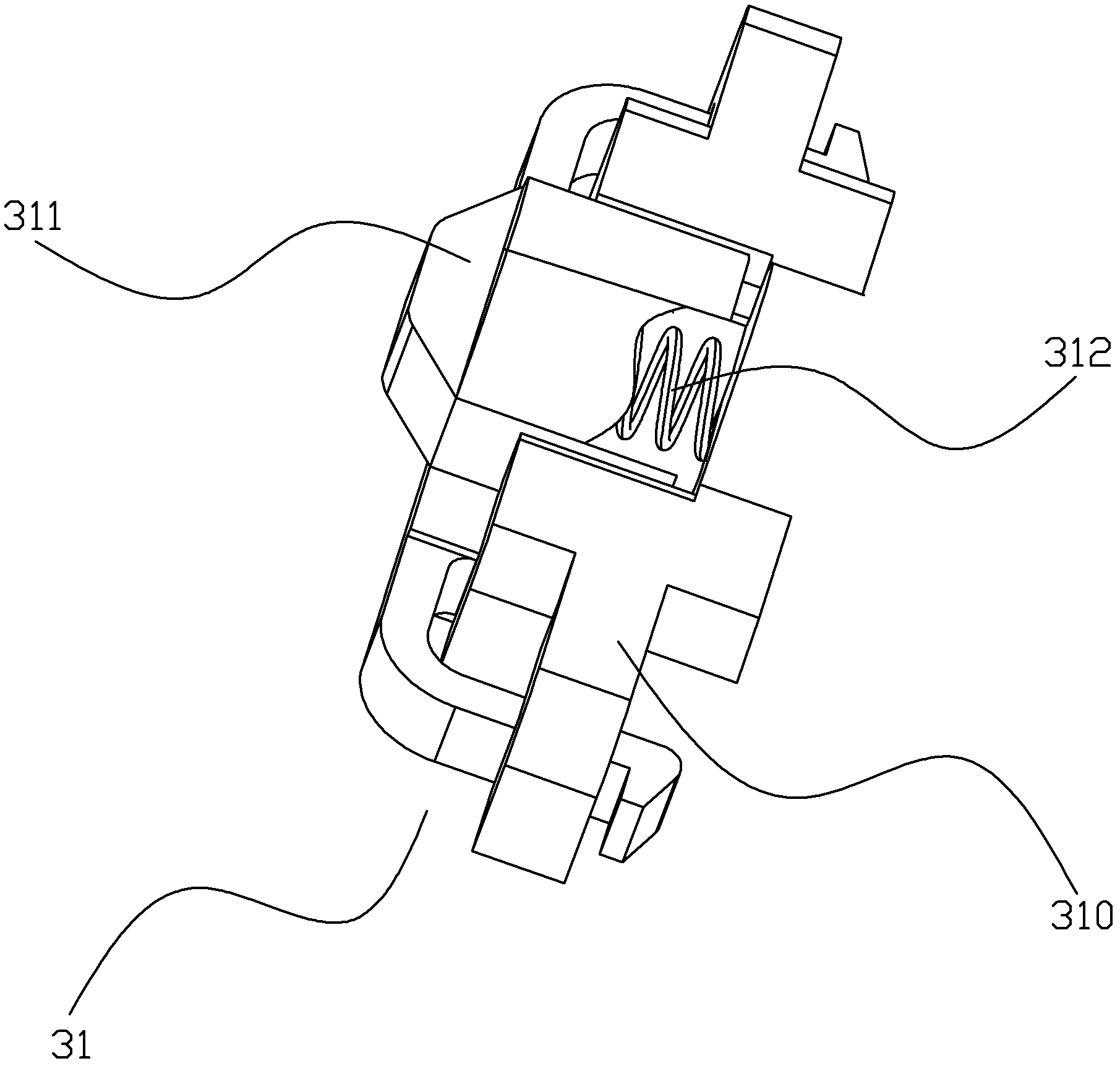

[0016] Further, two symmetrical fixed brackets 310 are processed on the left and right sides of the middle end of the top of the word cart 3, and then the guide slider 311 that can be inserted and buckled on the fixed bracket 310 is processed, and finally the compression spring 312 is installed on the fixed bracket. 310 and the guide slider 311 form a word car spring frame 31, and the compression spring 312 makes the guide slider 311 move forward and backward relative to the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com