Vertical microporous oil press and control device thereof

A technology of control device and oil press, applied in presses, manufacturing tools, etc., can solve the problems of high physical strength of operators, poor sanitary conditions, affecting oil yield, etc., and achieve the effect of thorough pressing, eliminating accidents and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] The present invention is described in detail again below in conjunction with accompanying drawing:

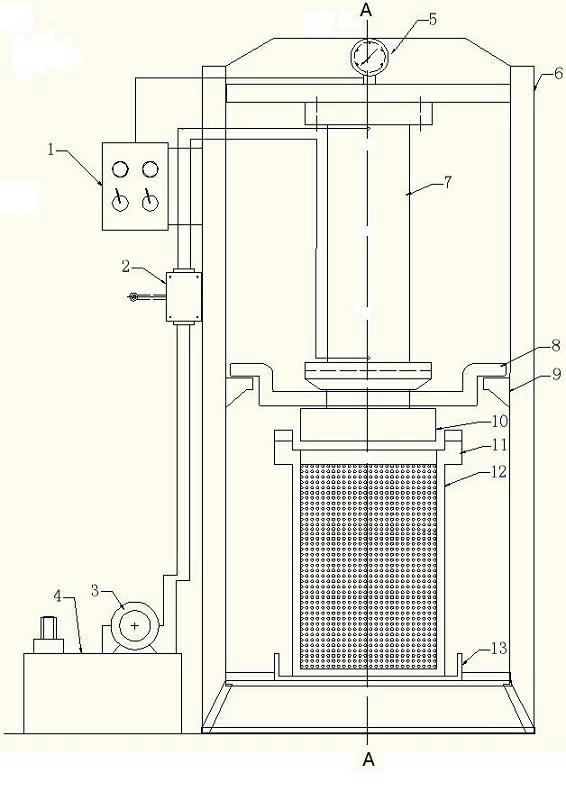

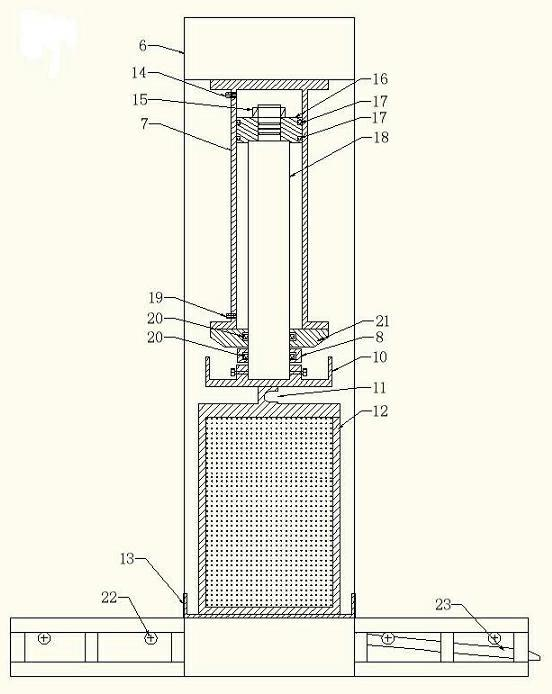

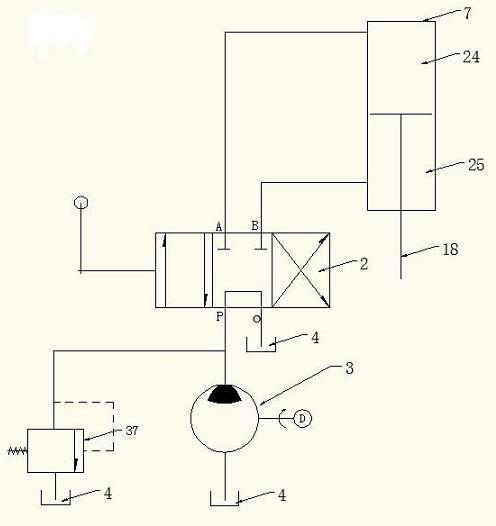

[0029] combined with figure 1 , 2 Explanation: This vertical oil press and its control device include a frame 6 erected on the horizontal ground, and an oil cylinder 7 is placed in the center of the frame. It is connected with the manual reversing valve 2, and an interface on the upper end of the oil cylinder 7 is equipped with an electric contact pressure gauge 5. The bracket 9 is fixed in the middle of both sides inside the frame, the hook lifting device 8 is set on the piston rod 18 on the upper part of the pressing plate 10 through the lower end of the piston, and the disc-shaped pressing plate 10 is installed on the lower end of the piston rod 18, and the pressing barrel 12 is A hollow drum with a wall thickness of 11mm, with a front and a reverse hook 11 welded on the mouth of the barrel, above 20mm at the bottom of the barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com