Manipulator, method for manufacturing same and application method of manipulator

A technology of manipulators and manipulators, applied in the field of manipulators, can solve the problems of unreasonable structural design of manipulators, high price of manipulators, and difficulty in flexible use, etc., and achieve the effect of simple and ingenious structure, small size, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

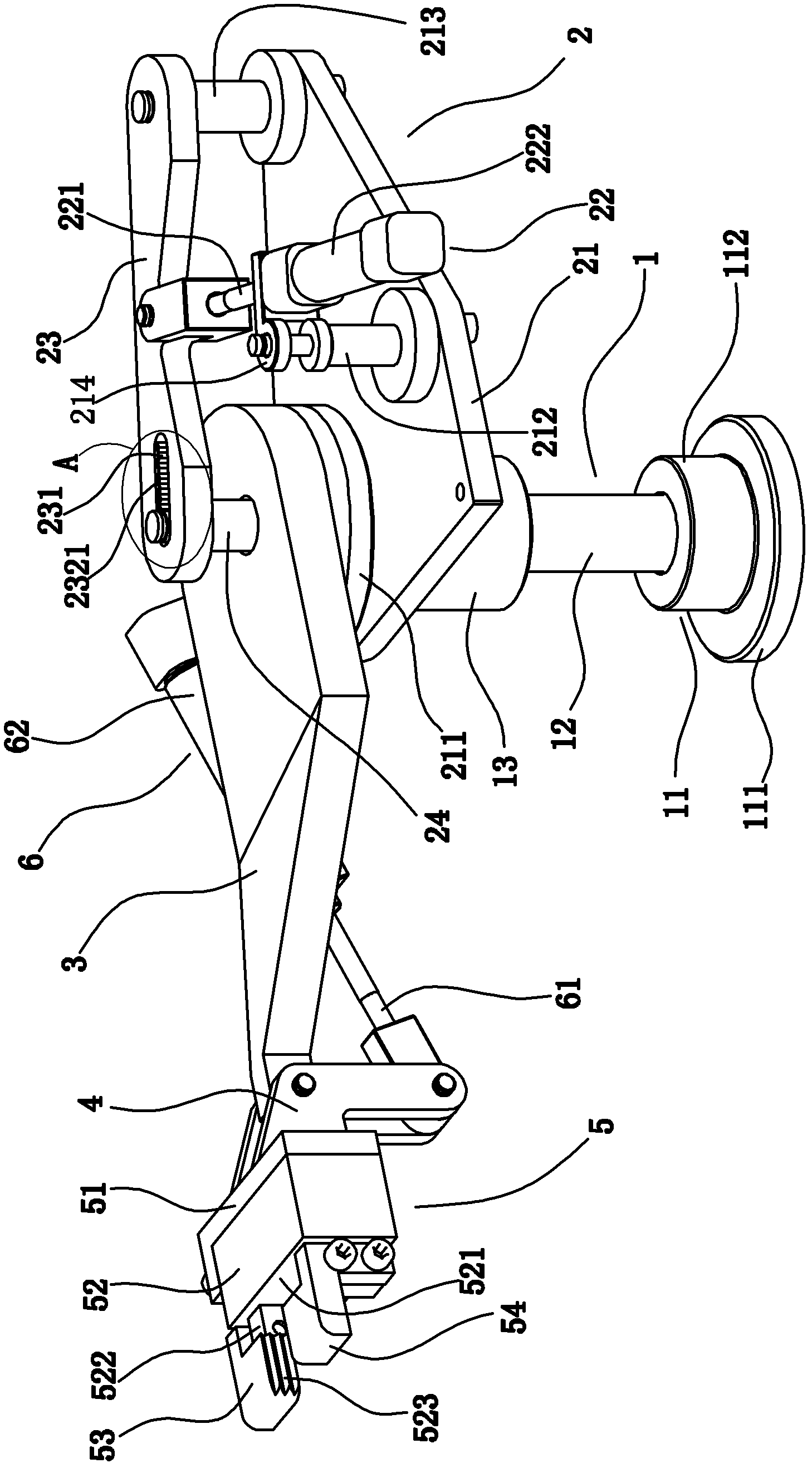

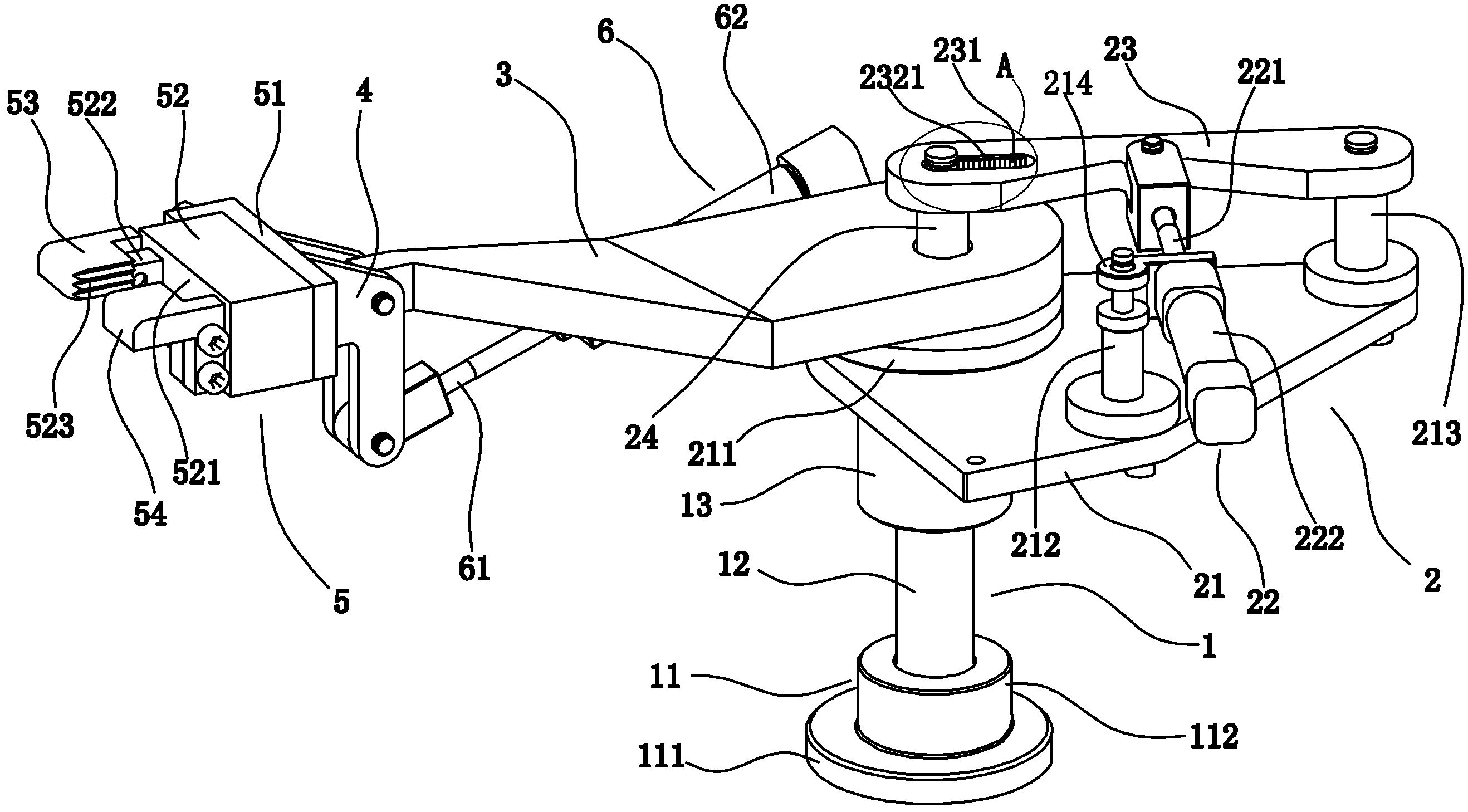

[0030] Example: see figure 1 with figure 2 , the preparation method of a kind of manipulator of the present invention, it comprises the following steps:

[0031] (1) Prepare a height adjustment device 1, including preparing a base 11, a column 12 and a rotating member 13 respectively, fixing the column 12 to the base 11, and setting the rotating member 13 on the base 13 so that it can rotate up and down. The upper end of the column 12 can adjust the vertical height of the manipulator through the height adjustment device 1;

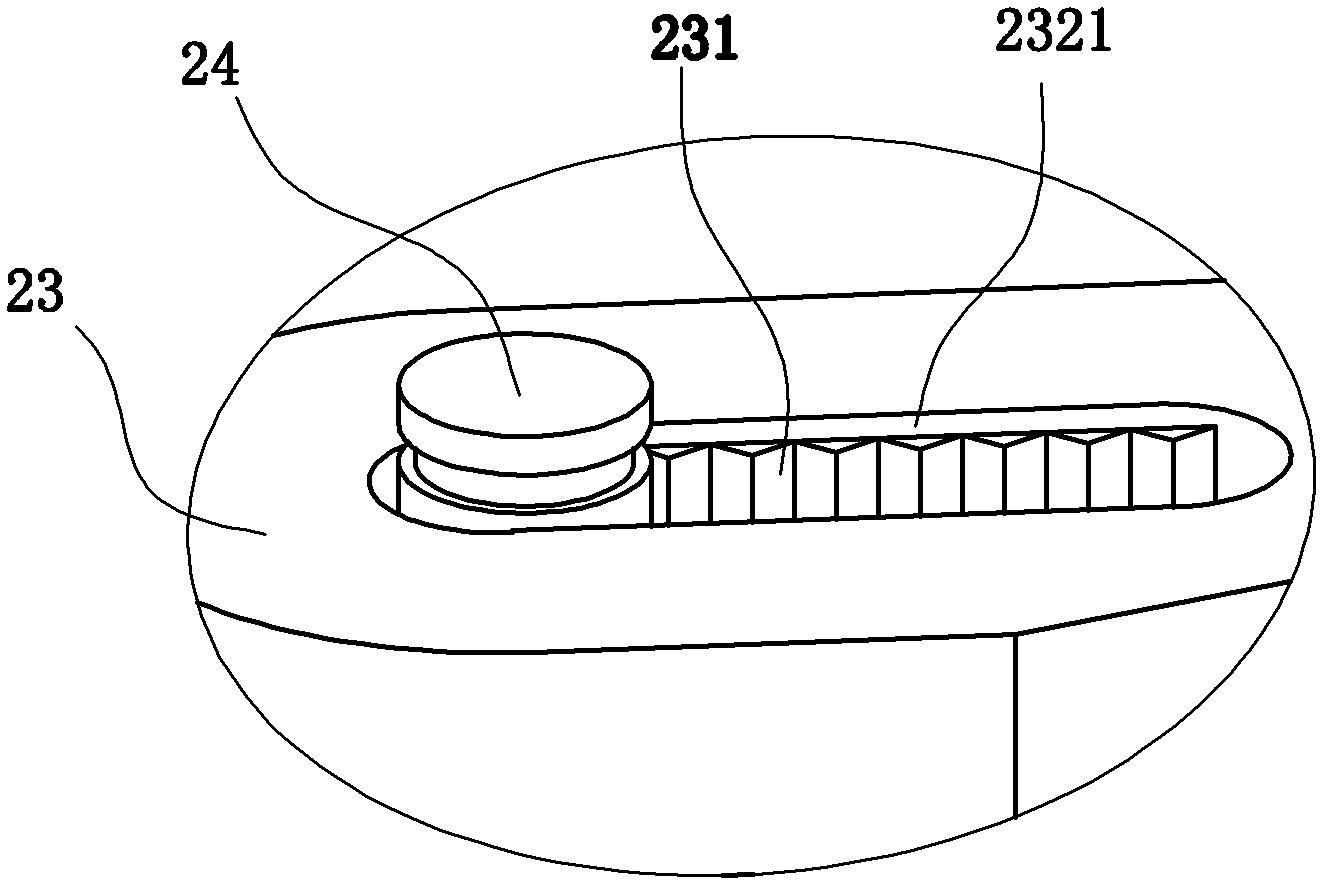

[0032] (2) Prepare a horizontal swing assembly 2, including preparing a bottom plate 21, a first cylinder 22, a first swing member 23 and a first rotating shaft 24 respectively, and the first rotating shaft 24 is rotatably arranged vertically on On the base plate 21, the first cylinder 22 and the first swinging member 23 are arranged on the base plate 21, the output shaft 221 of the first cylinder 22 is at the same level as the first swinging member 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com