Welder for automotive door bumper

A technology for automobile doors and anti-collision bars, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as workpiece deformation and poor weld seam consistency, improve weld flatness, reduce post-weld deformation, and eliminate The effect of substandard products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing implementation:

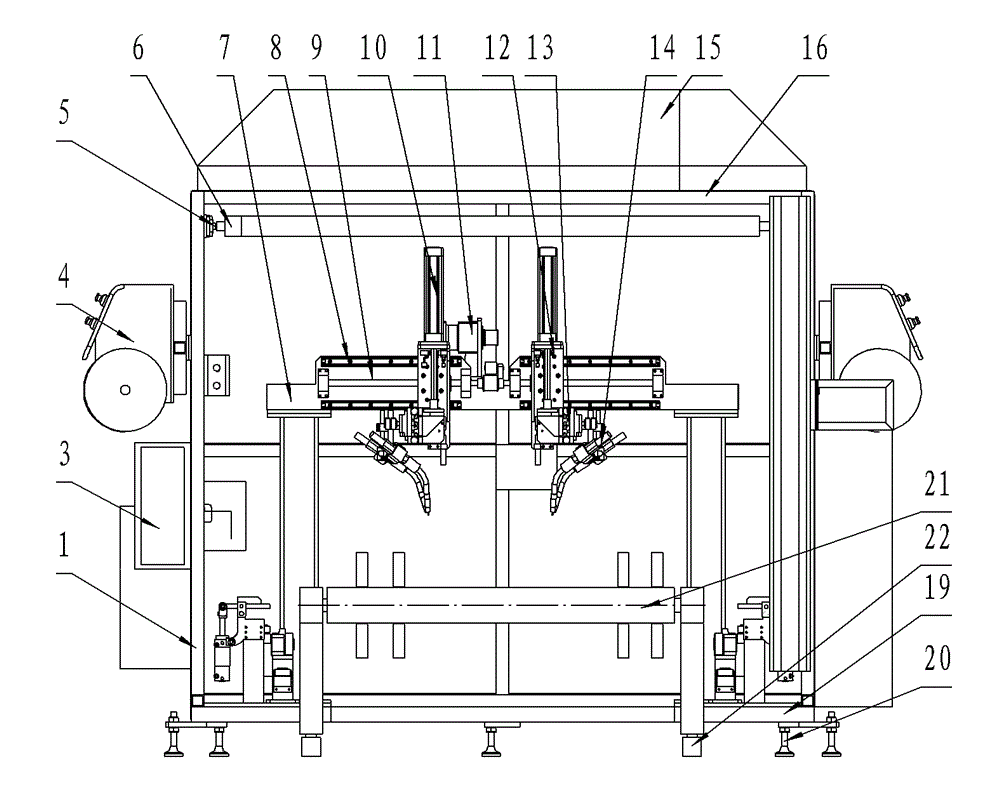

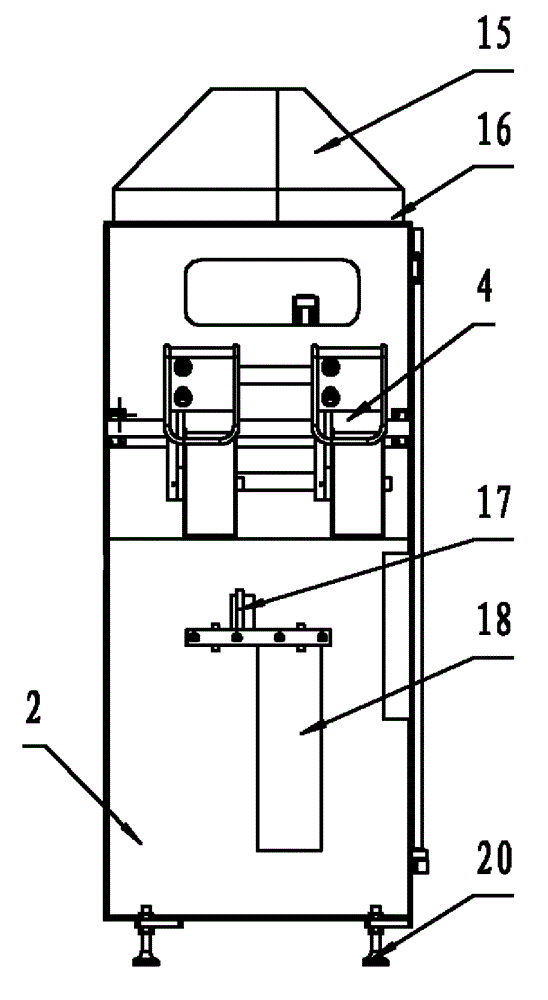

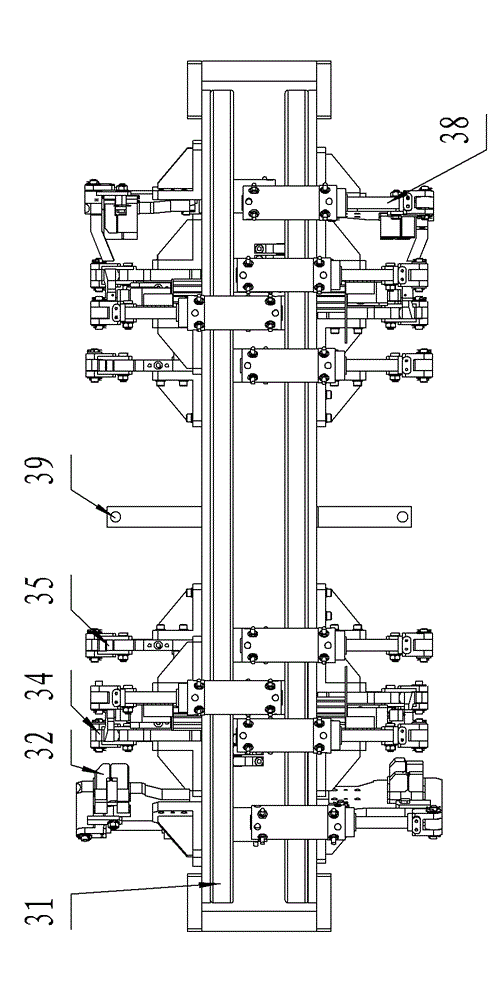

[0016] figure 1 , figure 2 The shown car door anti-collision rod welding machine has a welding frame 7, on which two sets of guide rails 8 arranged horizontally (set horizontally in the figure) are installed on the welding frame 7, and each set of transverse guide rails 8 is equipped with a welding torch intermediate connecting seat 12 , each welding torch intermediate connecting seat 12 is connected with its driving screw 9 through a screw nut, the screw rods of the two welding torch intermediate connecting seats 12 have opposite directions of rotation, they are connected by a coupling and driven by the same power transmission mechanism 11 are connected, each welding torch intermediate connecting seat 12 is equipped with a welding torch mounting frame 13 driven by an oil cylinder 10 through a guide rail arranged vertically (upright in the figure)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com