Magnesium alloy precision forging die and magnesium alloy precision forging process

A technology for forming molds and forming processes, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of uncontrollable slider movement, low production efficiency, difficult forming, etc., to eliminate adverse effects, Production efficiency assurance, the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

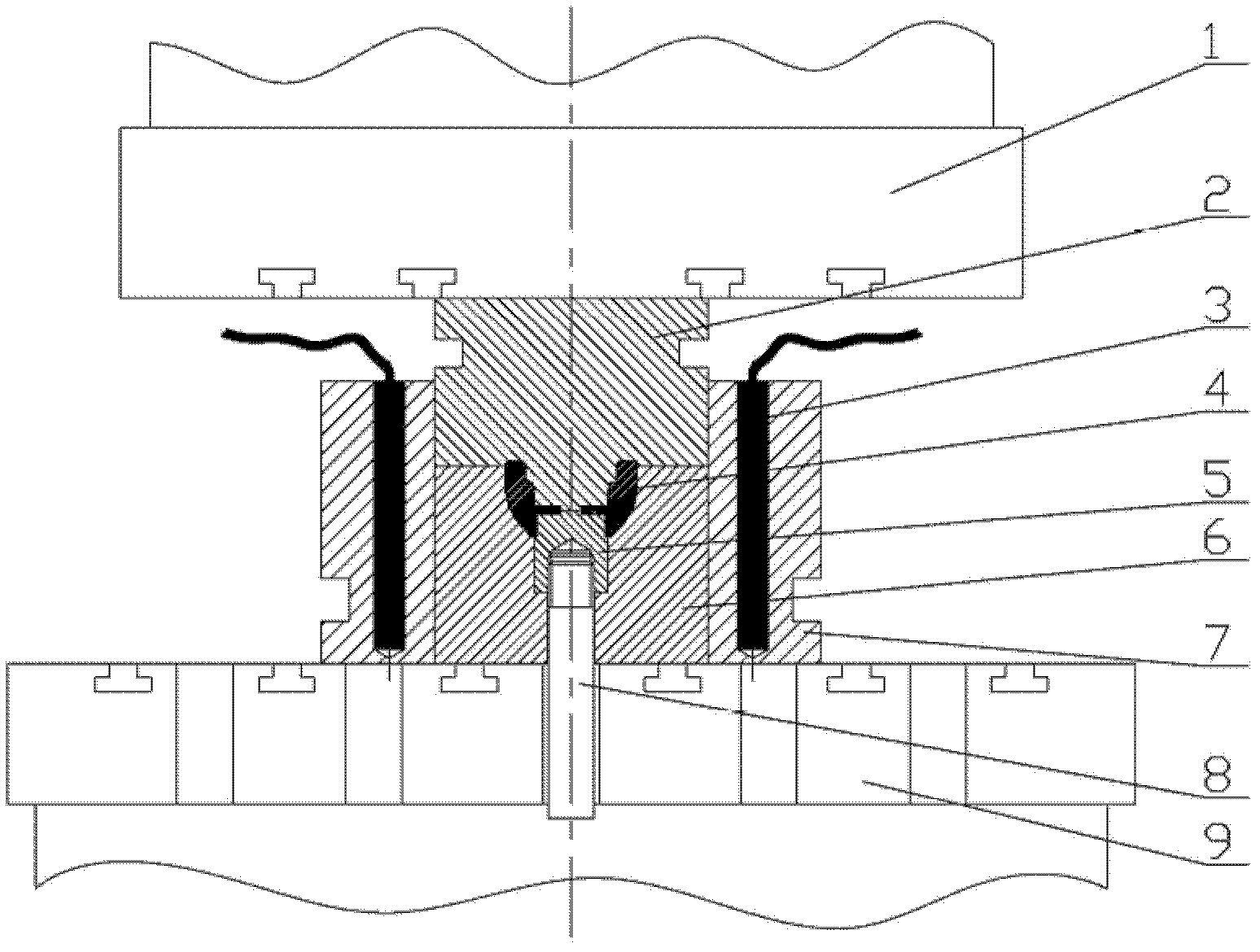

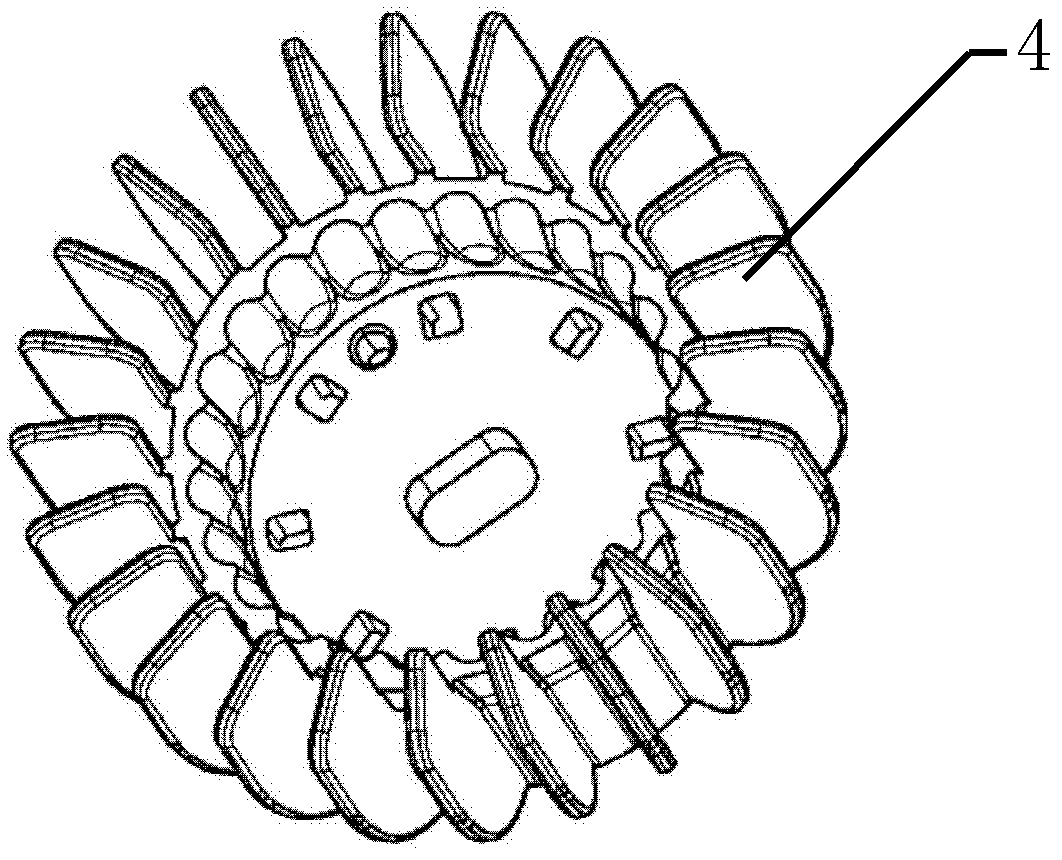

[0031] The structure diagram of the present invention is as figure 1 As shown, the magnesium alloy precision forging forming die of the present invention, the magnesium alloy precision forging forming die of the present invention includes a punch 2, a preheating device 3, a pusher block 5, a die 6, a mold base 7, and a push rod 8 , workbench 9, punch 2 is installed on the slider 1 of the servo press, preheating device 3 is installed in the mold base 7, the mold base 7 is fixed on the workbench 9 of the servo press, and the die 6 is fixed on the die On the seat 7, a push rod 8 is arranged between the die 6 and the die base 7, and the push rod 8 is provided with a push block 5, and the formed workpiece 4 is arranged between the push block 5 and the punch 2.

[0032] The above-mentioned preheating device 3 is an electric heating tube.

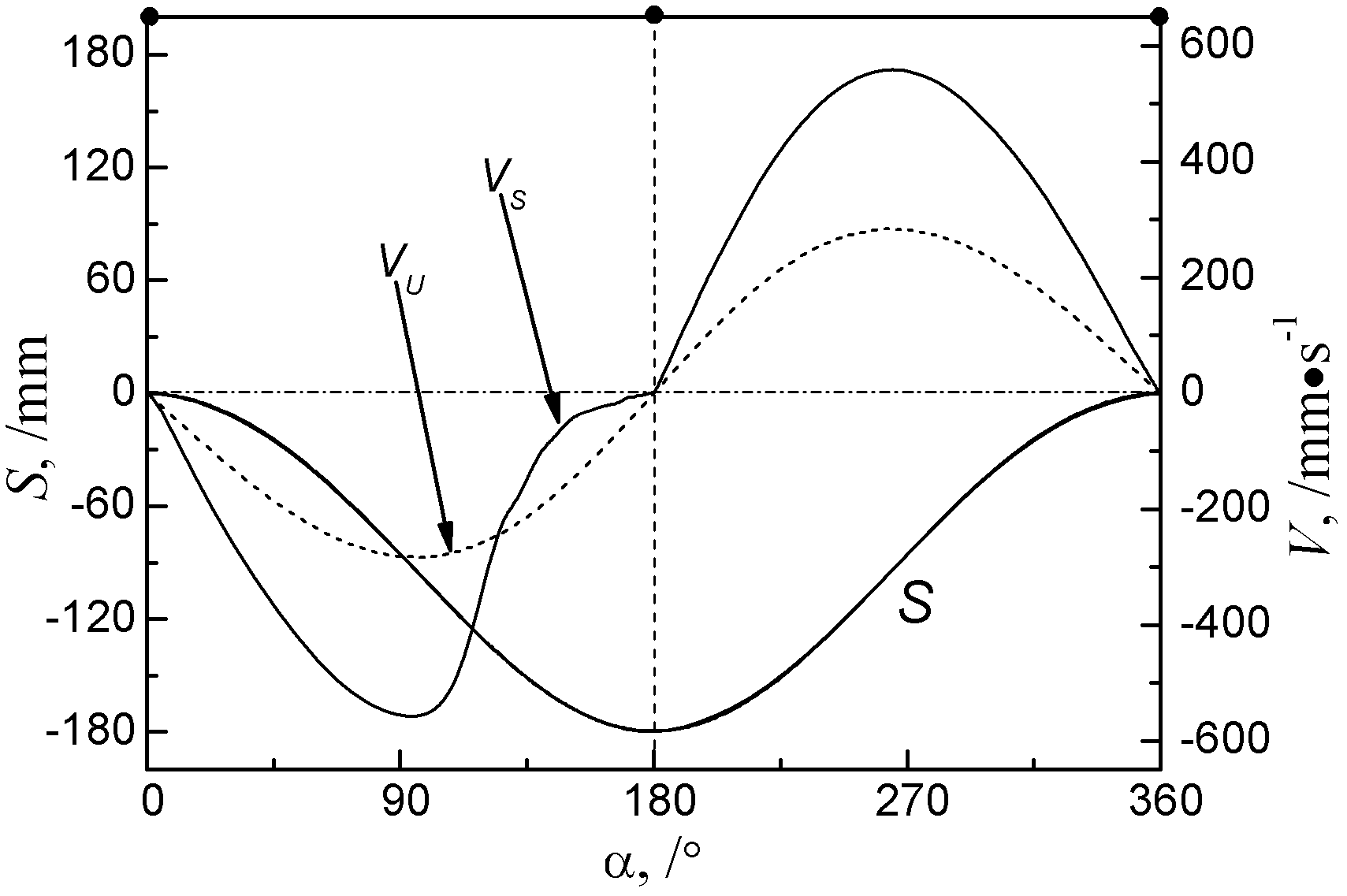

[0033] The above-mentioned servo press is a 1100kN servo mechanical press, the length coefficient of the connecting rod is 0.09-0.12, the nomina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com