Method for realizing live cleaning of secondary equipment

A technology for secondary equipment and electrified cleaning, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. The effect of secondary pollution and solving safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for electrified cleaning of secondary equipment is described below by taking the cleaning of a power distribution cabinet as an example.

[0025] In the live operation of the power distribution cabinet, a mixture of 78.5 grams of surfactants, 13.2 grams of cleaning aids, 6.7 grams of antirust and corrosion inhibitors, 1.6 grams of defoamers and 0.8 grams of enzyme preparations is used as a charged cleaning agent. The power distribution cabinet is spray cleaned. Among them, the surfactant is a mixture of 25.4 grams of fatty alcohol polyoxyethylene ether, 21.3 grams of triethanolamine oleate, 18.5 grams of alkyl phosphoric acid ester, and 13.3 grams of amide phosphoric acid ester. Wetting, solubilizing and emulsifying abilities; the cleaning aid is sodium hydroxide, which has a synergistic effect with surfactants, strengthens the decontamination ability, prevents precipitation, clarifies the solution, prevents freezing, and prevents corrosion; the antirust and co...

Embodiment 2

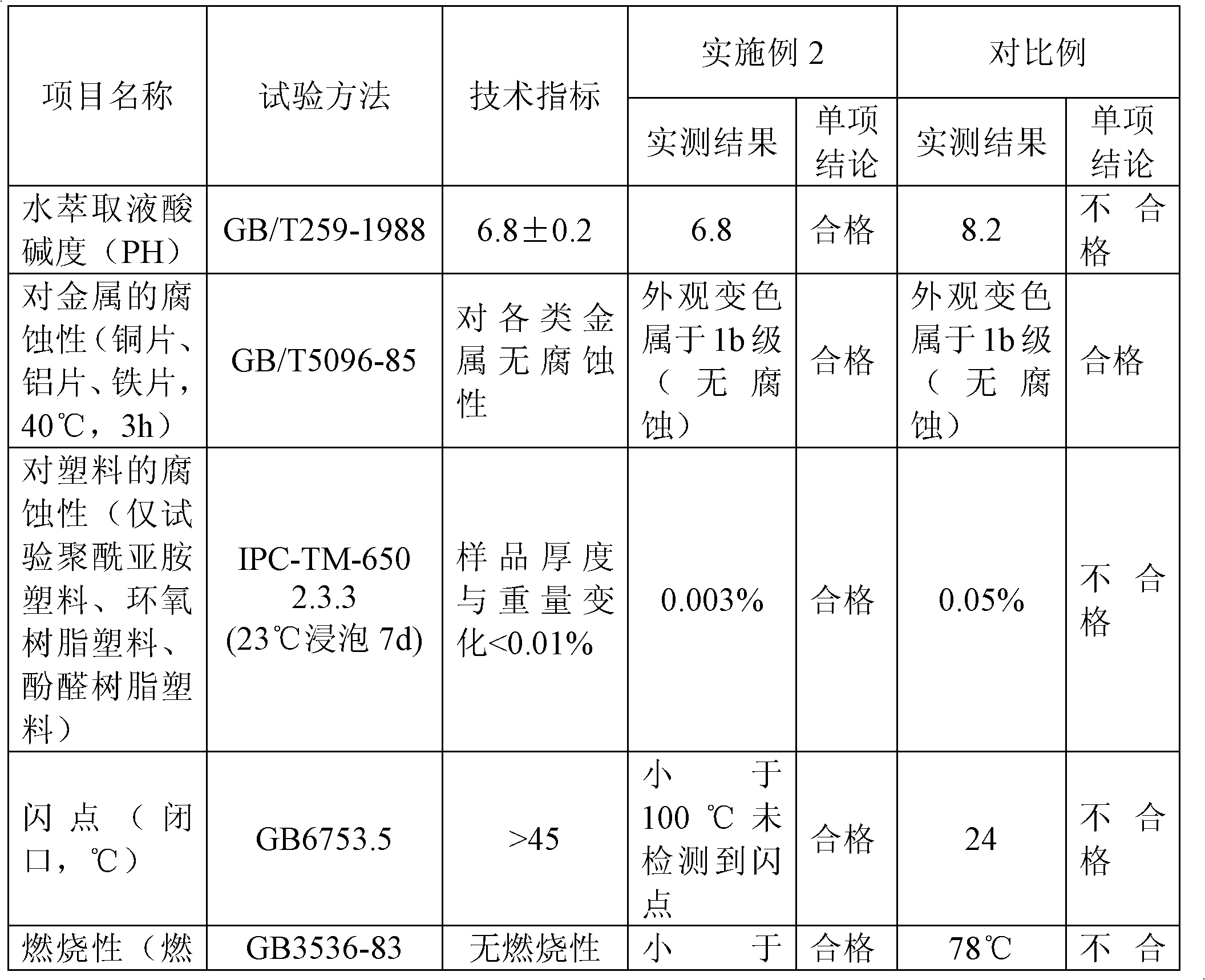

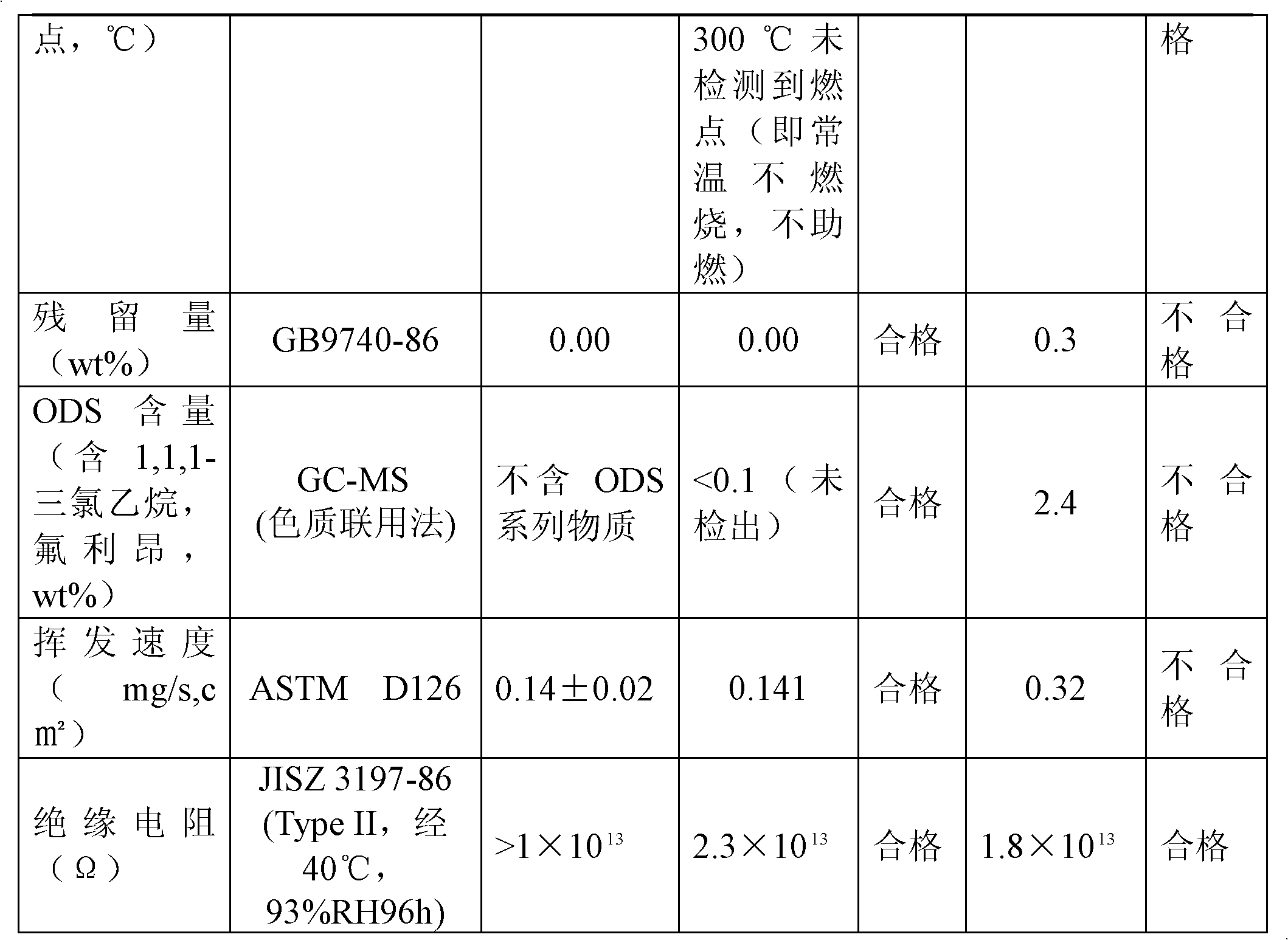

[0029] Use the mixture of 78.5 gram surfactants, 13.2 gram cleaning aids, 6.7 gram antirust and corrosion inhibitors, 1.6 gram defoamers and 0.8 gram enzyme preparation as charged cleaning agent, wherein, surfactant is 25.4 gram fatty alcohol polyoxygen A mixture of vinyl ether, 21.3 grams of triethanolamine oleate, 18.5 grams of alkyl phosphate, and 13.3 grams of amide phosphate, the cleaning aid is sodium hydroxide, the antirust and corrosion inhibitor is sodium tripolyphosphate, and the defoamer is 0.9 grams The mixture of organosiloxane and 0.7 g of nonylphenol polyoxyethylene ether, and the enzyme preparation is alkaline protease, which can be prepared by mixing evenly. Then, test the pH of the water extract of the charged cleaning agent, corrosion to metals, corrosion to plastics, flash point, flammability, residual content, ODS content, volatility, insulation resistance, the tests are listed in Table 1 result.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com