Self-cleaning filter for cigarette factories

A self-cleaning filter, cigarette factory technology, applied in the direction of dispersed particle filtration, application, household heating, etc., can solve the problems of unsuitable for large air volume filtration, shorten the service life of filter materials, and cause great damage to filter materials, etc., to achieve Meet the requirements of large air volume purification and filtration, increase the cross-sectional area of the air inlet, and increase the effect of the filtering cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

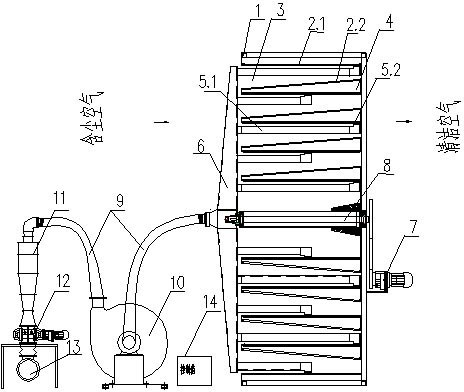

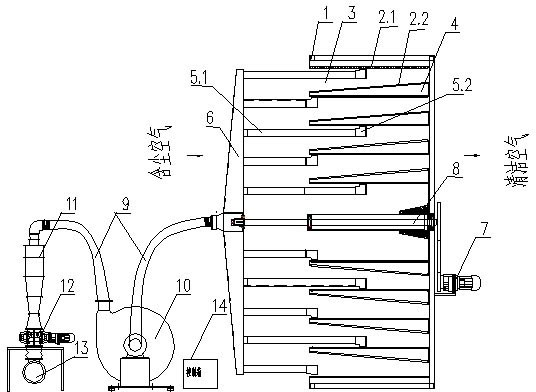

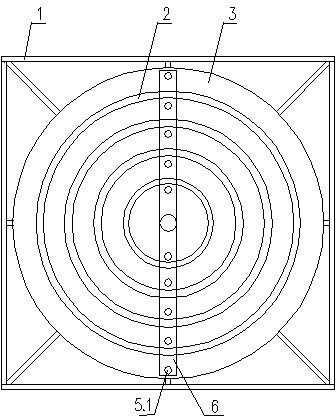

[0018]Embodiment 1: referring to accompanying drawing, the self-cleaning type filter for cigarette factory of the present invention, in square support 1, built-in several concentric single-slope transverse U-shaped filter rings 2 (cross-section is right-angled trapezoidal) that fit alternately, filter ring length 1.2 The U-shaped straight surface is provided with a filter screen 2.1 composed of a plurality of arc-shaped inserts adjacent to each other, and the inclined surface 2.2 and the bottom surface are closed, so that the adjacent filter ring 2 forms a tapered filter inlet 3 with a wide cross-section, and the reverse To the cone-shaped air outlet 4 (filtering on the filter surface side). The filter screen 2.1 is a film-coated filter material covered with a PTFE polyester porous membrane on the oil-repellent and water-repellent plush filter surface. Rotary suction device for the filter surface in each filter ring, screw / nut rotating shaft 8 driven by power 7, and a rotating...

Embodiment 2

[0020] Embodiment 2: As in Embodiment 1, in order to make full use of the four corners of the circumscribed square frame, it is also possible to place a triangular arc plate filter unit or a plate bag compound filter unit between the outermost filter ring and the four corners of the square support to further Increase the filter area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com