Method of barrel electroplating with aluminum or aluminum alloy

An aluminum alloy and barrel plating technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems such as the inability to fully ensure that the cathode and the object to be plated contact the object to be plated, and the poor electrification of the object to be plated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

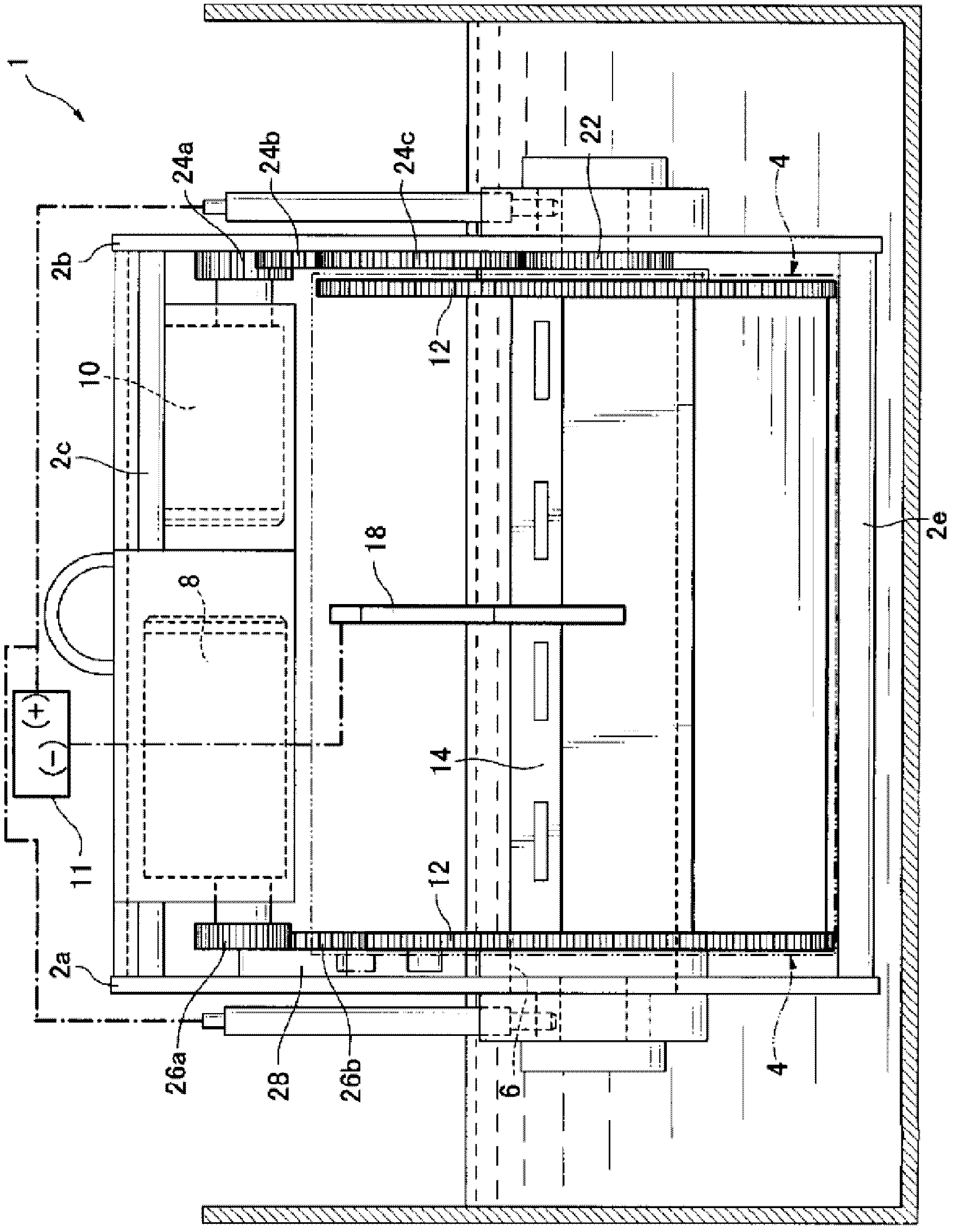

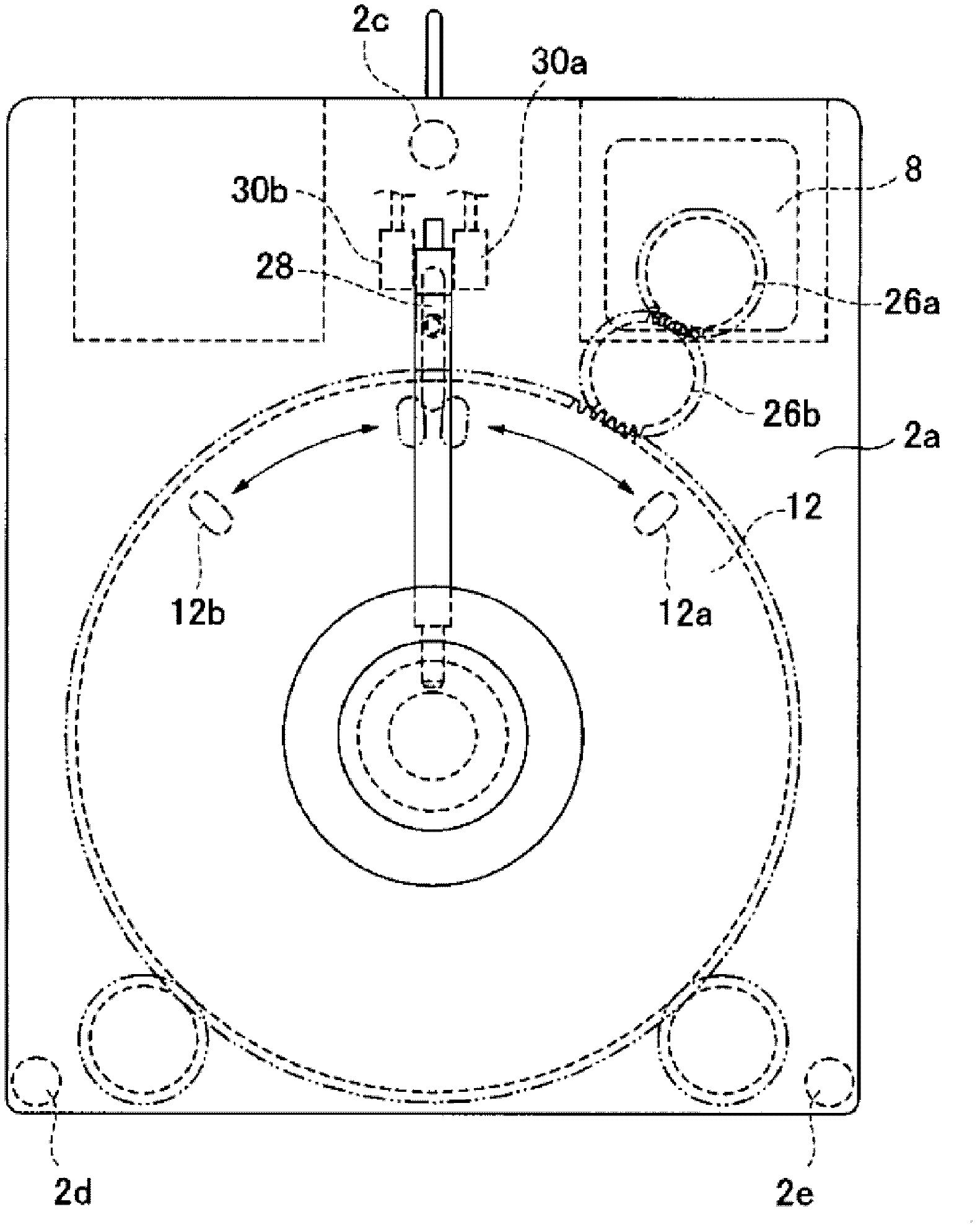

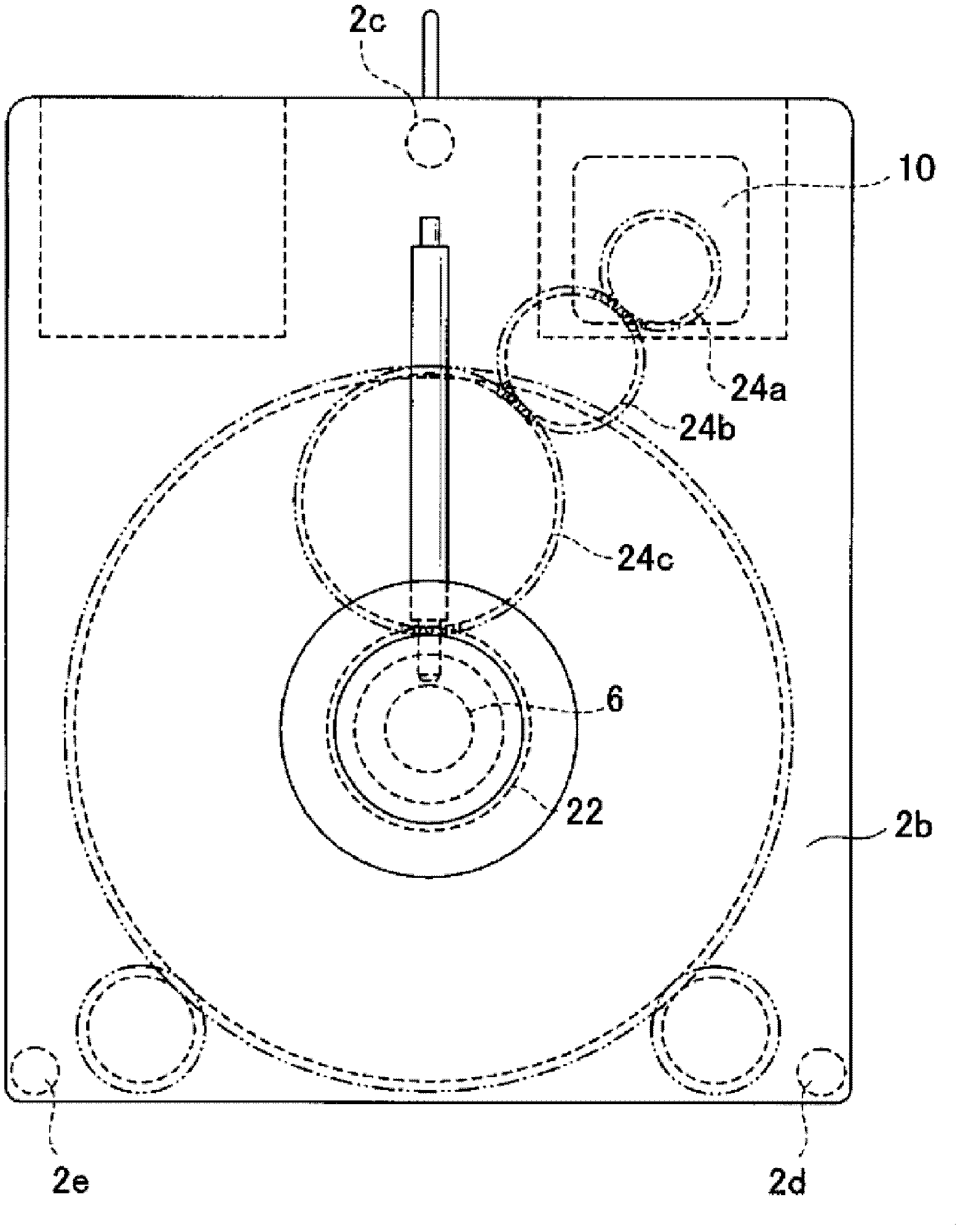

Method used

Image

Examples

Embodiment 1

[0107] An aluminum alloy was plated on an M8 bolt using a barrel plating apparatus 1 (5 kg barrel) having an Al plate as a cathode and an Al as an anode. The input amount of bolts is varied between 1 and 5kg. First, as a pretreatment, alkali degreasing, alkali electrolytic cleaning, and pickling are performed, Ni plating is performed, water washing is sufficient, and water is replaced with ethanol, followed by drying.

[0108] For the composition of the plating bath, to AlCl 3 Al-Zr-Mn was prepared by adding 10 g / L of manganese chloride and 1 g / l of zirconium chloride to a bath prepared by mixing and melting 1-methyl-3-propylimidazolium bromide at a molar ratio of 2:1. Alloy plating baths. In a dry nitrogen atmosphere, immerse in the aforementioned Al-Zr-Mn alloy plating bath maintained at 100°C for 5 minutes, and then use the same plating bath with a pulse current (duty ratio: 1 / 1, ON time: 10ms, OFF Time: 10ms) Plating Al-Zr-Mn alloy. The plating condition is set to a cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com