Manufacturing method of multilayer circuit board and laminated structure for multilayer circuit board

A technology of a multilayer circuit board and a manufacturing method, which is applied in the direction of manufacturing a multilayer circuit, etc., can solve the problems of high manufacturing cost, poor thickness uniformity of the insulating layer, lamination depression of the insulating layer, etc., so as to reduce the manufacturing cost and reduce the number of grindings. , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

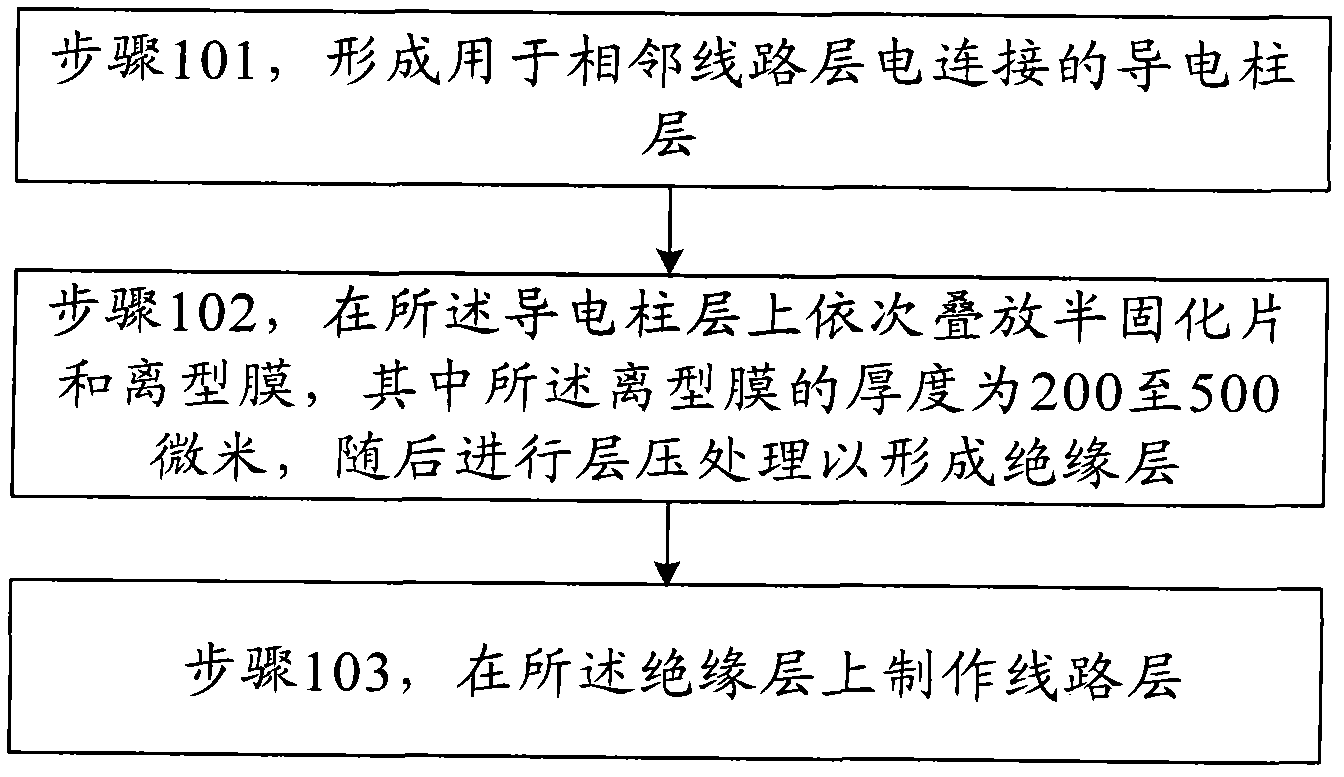

[0021] The present invention provides a kind of manufacturing method of multilayer circuit board, it is characterized in that, comprises the following steps:

[0022] forming a conductive column layer for electrical connection of adjacent circuit layers;

[0023] Laying a prepreg and a release film sequentially on the conductive post layer, wherein the release film has a thickness of 200 to 500 microns, followed by lamination to form an insulating layer;

[0024] A circuit layer is fabricated on the insulating layer.

[0025] Preferably, in each embodiment of the present invention,

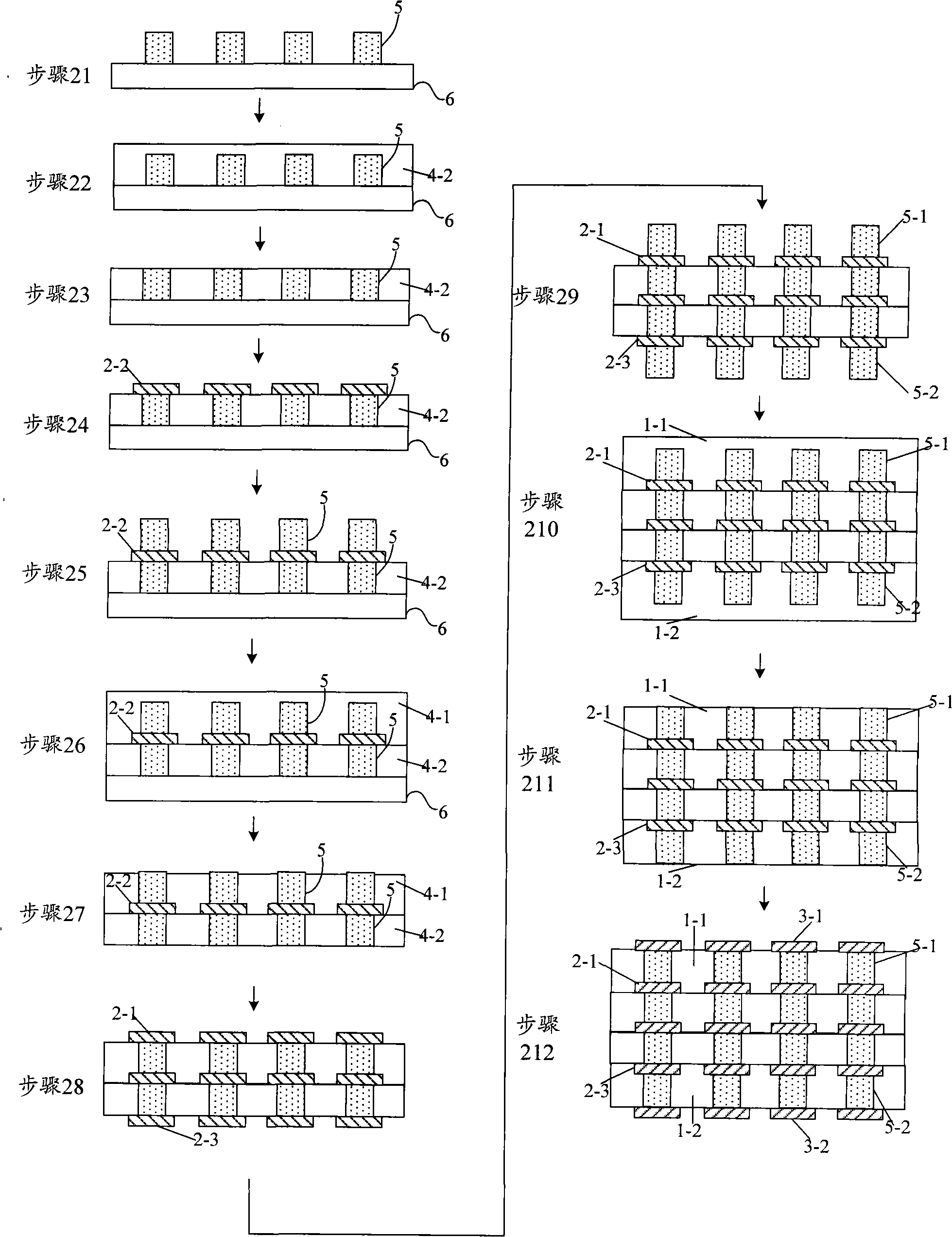

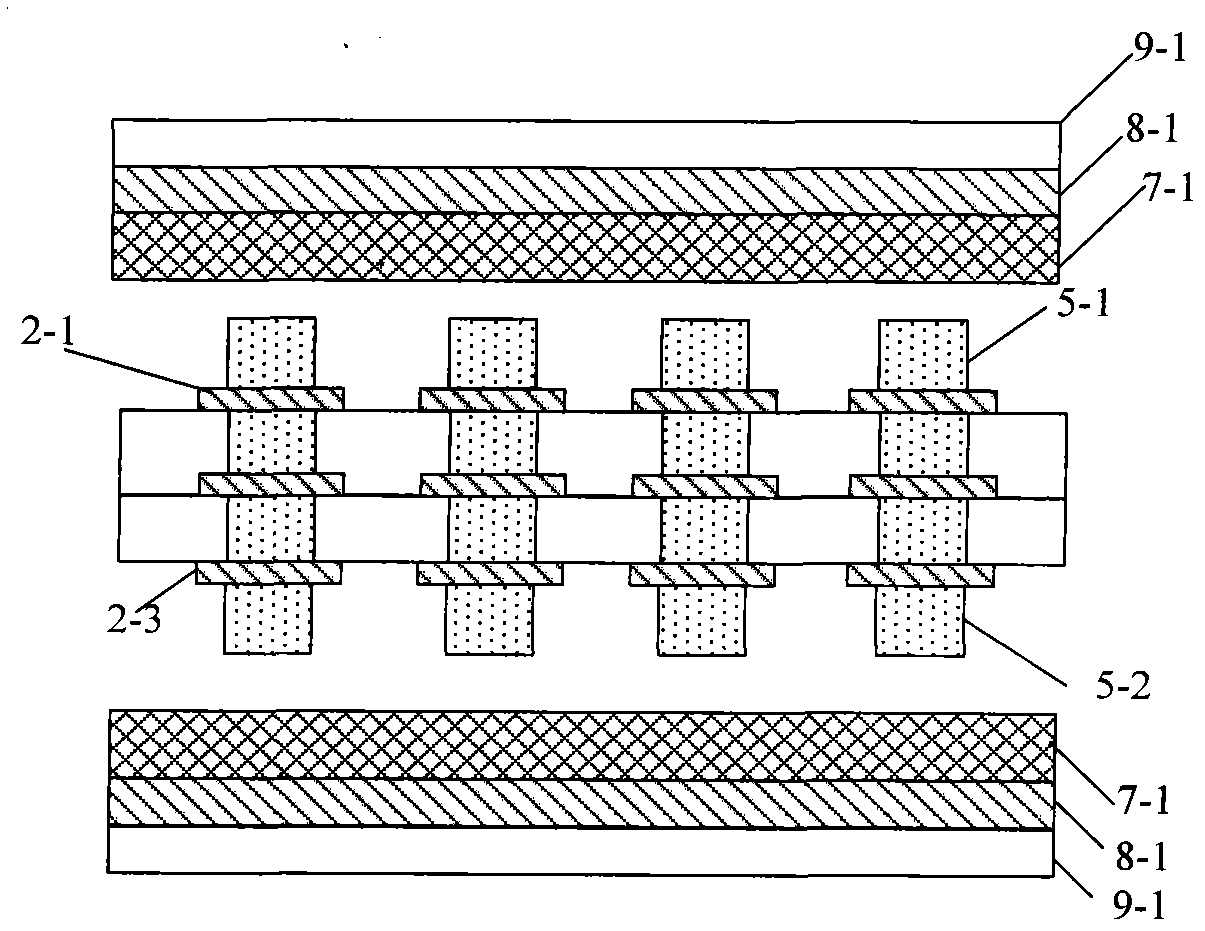

[0026] The forming of the conductive column layer for electrical connection of adjacent circuit layers includes: forming a first conductive column layer and a second conductive column layer;

[0027] The step of sequentially stacking a prepreg and a release film on the conductive column layer, followed by lamination to form an insulating layer includes: sequentially stacking a prepreg and a rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com