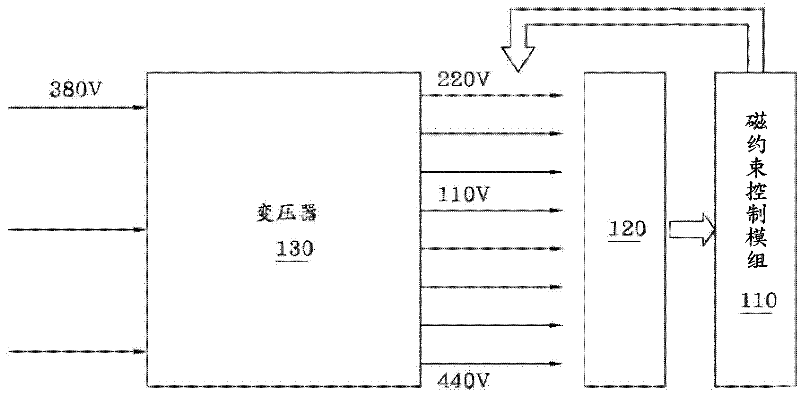

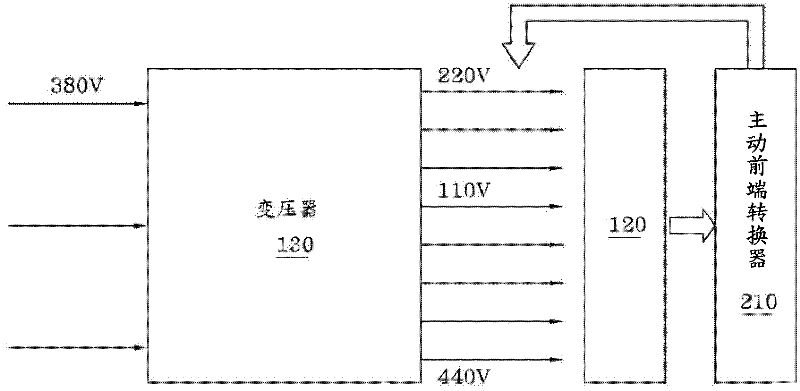

Product quality aging testing system

A technology for aging testing and product quality, which is applied in measuring electricity, measuring devices, and measuring electrical variables, etc. It can solve problems such as low feedback energy, frequency converter explosion, and high current harmonic content, so as to reduce transformer load and load cost. , Improve the effect of power quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

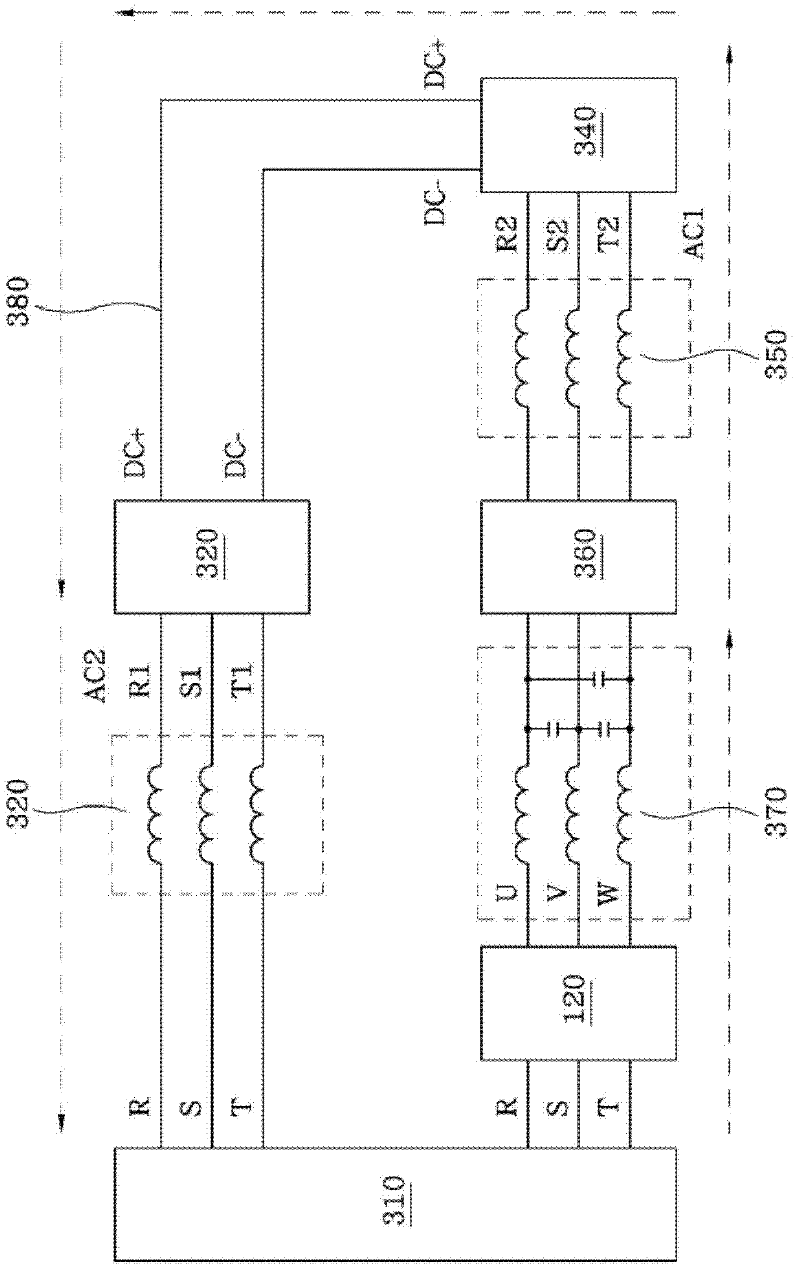

Embodiment Construction

[0035] In order to make the description of the present invention more detailed and complete, reference may be made to the accompanying drawings and various embodiments described below, and the same numbers in the drawings represent the same or similar elements. On the other hand, well-known elements and steps have not been described in the embodiments in order to avoid unnecessarily limiting the invention.

[0036] In the detailed description and the claims, the description of "coupled with" can generally refer to an element being indirectly connected to another element through other elements, or an element is connected without other elements. Connect directly to another component.

[0037] In the detailed description and claims, "a" and "the" can generally refer to a single or plural, unless there is a special limitation on the articles in the context.

[0038] As used herein, "about," "approximately," or "approximately" is used to modify any quantity that may vary slightly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com