Flat cable extruder head free of deviation regulation

A flat cable, extrusion head technology, used in cable/conductor manufacturing, conductor/cable insulation, circuits, etc., can solve the problems of plastic extrusion that cannot be uniform, wasteful, and uneven extrusion pressure

Active Publication Date: 2013-08-14

ECHU SPECIAL WIRE & CABLE KUNSHAN CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to match the combination of the unit and the reinforcement of the control cable, the outer sheath is evenly extruded around the unit core, and the mold core is also processed from the original cone into a flat shape to match, so that the extruded The material flow space becomes extremely complicated. When the cone suddenly becomes flat, it forms a vortex with the space body. The vortex will make it difficult to grasp the design size of the shape model during the extrusion process. It takes multiple adjustments and trial production to achieve the desired effect.

The second is that the eddy current will also cause uneven extrusion pressure, which makes it difficult for the operator to control during the deviation adjustment process.

The third is that the traditional adjustable eccentric machine head is designed to meet the needs of a machine that can manufacture cables of various specifications. And it is convenient for the operator to disassemble. The center point is often shifted when the specification is changed, so that the plastic extrusion of the shape cannot be uniform. Uniformity, the adjustment needs to be carried out under the dynamic condition of extrusion while adjusting, which puts forward high requirements on the operation level, and also requires a certain adjustment process and time

Waste a lot of cable core semi-finished products and outer sheath materials, increase manufacturing energy consumption and cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

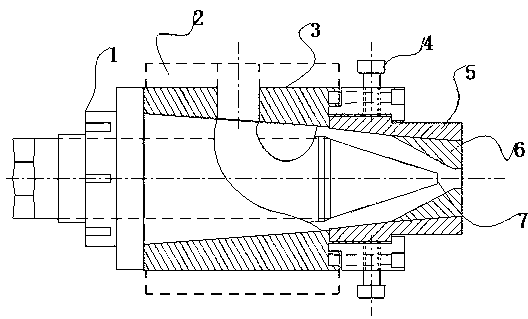

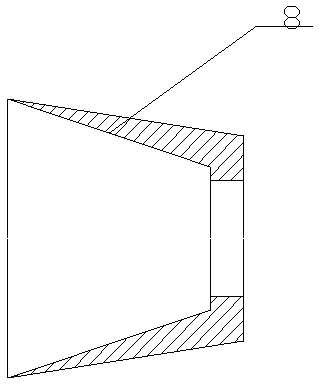

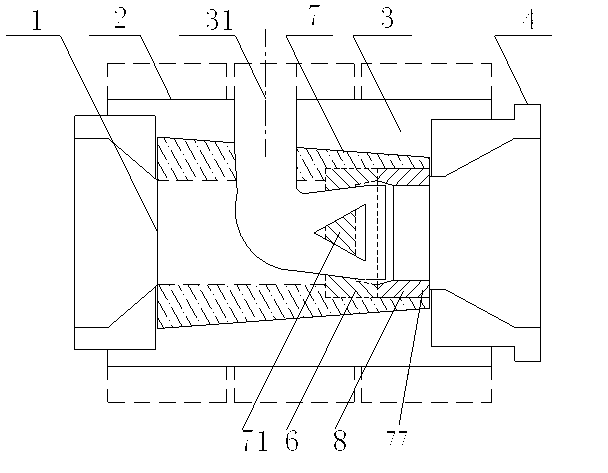

The invention relates to a cable extruder head, in particular to an extruder head for a flat cable. The invention aims to meet the control requirement on the comprehensive function of a modern power and information transmission control system and invent a flat extruder head which has high forming quality, simple design structure and strong operability and is free of deviation regulation. For fulfilling the aims, the extruder head comprises a front baffle, an outer heating die, a head main body, a machine core, an inner die, an outer die and a rear baffle; the heating die is coated around the head main body; the machine core is arranged in the head main body; the inner die is arranged in the machine core; the outer die is connected to the rear end of the inner die; the rear baffle is arranged behind the outer die; a double-sided symmetrical drainage groove is arranged on the surface of the machine core; die slots are arranged at the tail end of the machine core and are used for mounting the inner and outer dies; a convection port is formed at the end position of the double-sided symmetrical drainage groove; the convection port is connected with feed inlets on both upper and lower surfaces of the inner die; the lateral surface at one end of the inner die is provided with a core wire inlet; the other surface of the inner die is connected with the outer die; an inlet of the outer die is coincided with an outlet of the inner die; and the inlet of the outer die and the outlet of the inner die are arranged in the die slots at the tail end of the machine core.

Description

technical field [0001] The invention relates to a cable extrusion head, in particular to a flat cable extrusion head. Background technique [0002] At present, the wire and cable manufacturing and processing outer sheath extrusion process generally adopts such as figure 1 The extrusion head shown performs the extrusion process. Its structure and processing principle are: the main body of the machine head, with a heating system on the periphery, protects and fixes the position of the extrusion orientation core, so that the plastic can be kept plasticized and oriented during the continuous extrusion process. The plastic is extruded from the flow channel opening of the funnel into the flow channel connected to the core by the extruder. The flow channel is designed as a groove with a smooth and curved turn. The direction of the plastic along the flow channel changes from vertical to horizontal. The plastic At the same time, the flow is shunted by the middle part of the core ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B13/24H01B13/14

Inventor 李军杨黎歌

Owner ECHU SPECIAL WIRE & CABLE KUNSHAN CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com